- Surcotec (0.09 MB)

/ MEDIA STATEMENT / This content is not written by Creamer Media, but is a supplied media statement.

The marine industry is a notoriously harsh environment for equipment, parts and components due to accelerated corrosion in a seawater atmosphere and severe operating conditions. Leading thermal spray company, Surcotec, in partnership with Thermaspray, offers a range of high quality thermal spray coating solutions as corrosion preventative measures that provide long-term protection for subsequent extended equipment lifespan and reduced total life cost.

Surcotec Marketing and Sales Manager, Ian Walsh, gives an overview of the Western Cape marine market which is predominantly based in Cape Town and Saldanha Bay: “Cape Town, a general harbour with a thriving container operation, fishing, general cargo and a small oil terminal, is a hub for the oil & gas industry and presents a great potential. The deep draft Saldanha Bay port can accommodate large oil tankers and is one of the main iron ore export facilities. The surrounding areas boast a steel manufacturing plant and one of the country’s largest oil storage facilities.”

As Cape Town’s reputable and fully equipped thermal spray company, Surcotec is perfectly positioned to assist in marine applications. “It is difficult to predict market values due to marine repair being highly volatile with harbour usage sporadic at best but we claim the lion’s share of the thermal spray market.” Walsh affirms considerable growth over the past three years in their in-situ machining service.

“A ship in harbour is a very expensive commodity and downtime can be a massive cost making it a highly competitive market. Most of these types of repairs are done on a round-the-clock basis so fast, quality service at short notice is vital, a reputation that Surcotec has earned.”

Walsh explains that many components installed on ships such as power plants, pumping systems and environment control systems are designed for optimum performance in a land-based environment. “The harsh environment experienced at sea often puts these systems outside their designed capabilities, reducing lifespan.”

Highlighting parts reliability as another concern to marine operators, Walsh notes that the availability of spare parts can be a major issue at sea or in a foreign port. Reliable parts that perform correctly between scheduled repair opportunities are critical to a marine vessel’s efficient operation.

Failures can lead to downtime and unscheduled calls to port which can cost the operator vast amounts. Failures at sea can also have severe consequences from a crew safety point of view and is thus taken very seriously by ship operators and insurers.

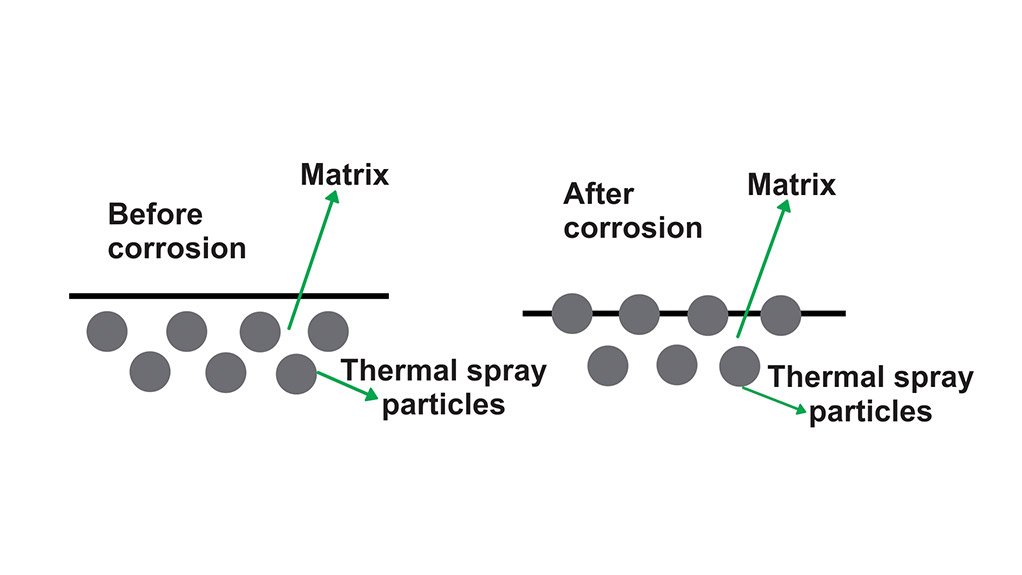

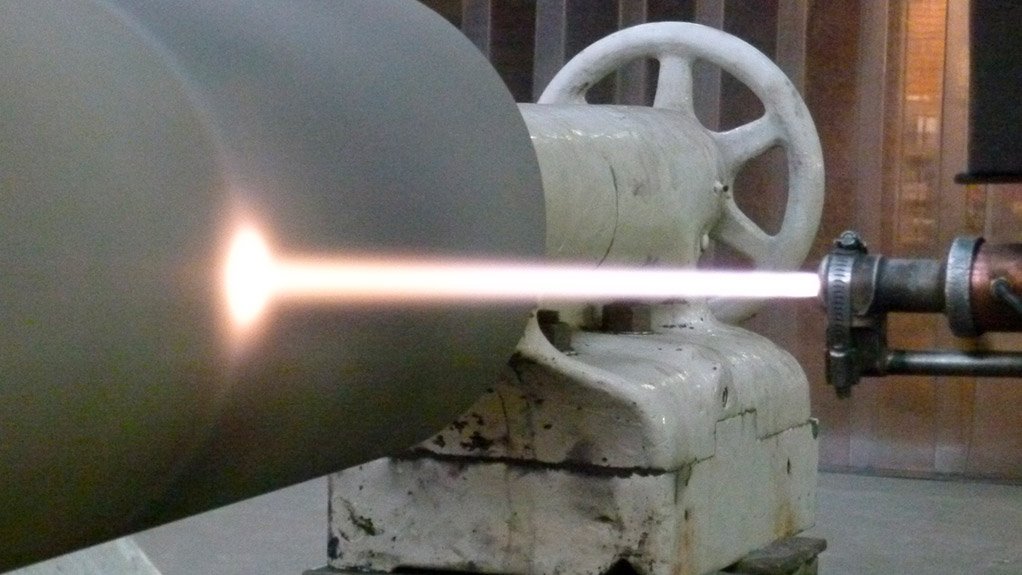

The application of specialised coatings offers a highly cost effective solution by providing a protective barrier to the corrosive attack to help extend the lifespan of equipment, parts and components. While most thermal spraying technologies are suited to shipping, Plasma, HVOF (High Velocity Oxy-Fuel) and Arc Wire Spraying applications are fast becoming the leading technologies.

Walsh explains that the type of coatings and processes used in the marine industry are determined by the specific application. On sea water-exposed parts for example, we see a large portion of HVOF applications employed on critical valve and wear parts. HVOF is increasing being used as a replacement for hard chrome on parts such as hydraulic shafts, pumps and seals. HVOF’s dense coatings reduce the possibility of sea water penetrating through to base material and causing premature failure.

Plasma offers a full range of ceramic coatings including hard wearing, insulation type and chemical attack-preventative coatings which are used extensively as a corrosion barrier. Due to the ability to operate for extended periods without lubrication, they can also serve as a low maintenance coating.

Walsh recommends arc sprayed coatings as a repair solution for worn parts. This technology is the most cost effective thermal spraying process for large objects and is suitable for large build ups and large scale corrosion protection on ocean-going shipping containers.

Surcotec undertakes both repairs of worn components as well as coating of new parts. Repairs form the majority of the scope of work on equipment including pumps (shafts, impellers, volutes), valves (spindles, gates, balls, casings and seats), hydraulic rods, winches (shafts, drums, hydraulic motors, hydraulic rods), propulsion (tail shafts, bow thruster parts), engine parts (cylinder heads, pistons, water jackets, governor parts, fuel pump, turbo parts). “We also do in situ line boring on stern tubes, winches, etc.,” adds Walsh.

“Many equipment manufacturers now offer a piece of equipment with the option of coatings being applied at manufacture for an added premium, and the equipment operators are becoming better acquainted with the benefits of coatings.”

Thermal spray coating technology is also becoming an increasingly viable corrosion preventative measure to provide long-term protection against corrosion on coastal infrastructures such as port facilities, bridges, pipelines, and highways.

Walsh affirms that Surcotec’s two-year partnership with Thermaspray has without any doubt had a positive impact on the business. “The partnership has added value through an increase in capital equipment such as the Plasma system and manipulating robots. We have access to Thermaspray technical back up and laboratory and have the added advantage of being able to forward repairs that are too big for our facility to handle to Thermaspray and maintain our high service levels and customer loyalty.”

Edited by: Creamer Media Reporter

EMAIL THIS ARTICLE SAVE THIS ARTICLE

ARTICLE ENQUIRY

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here