- Thermaspray (0.09 MB)

/ MEDIA STATEMENT / This content is not written by Creamer Media, but is a supplied media statement.

Thermally sprayed coating solutions, as provided by coating technology specialist, Thermaspray, ensures protection from wear, erosion and corrosion for a wide range of components found in the turbomachinery and rotating equipment industries. The application of a thermally sprayed coating leads to extended service life, reduced maintenance, increased uptime and production, and ultimately lower operational and ownership costs.

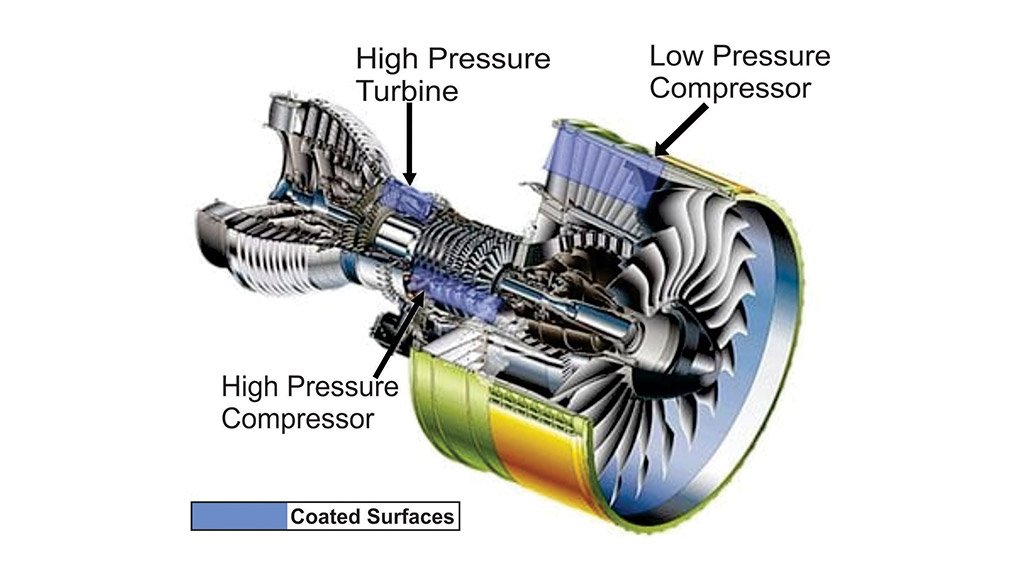

Corrosion and erosion of components affect a wide range of industrial applications and products in the processing and manufacturing industries, including the turbomachinery and rotating sectors. These types of wear result in a reduction in component service life, eventual failure of components, increased maintenance frequency with associated costs, costly downtime and subsequent production losses. Thermally sprayed coatings offer a solution; providing excellent protection against abrasion, corrosion and erosion, thermal degradation and high temperature oxidation on components including turbines and compressor rotors (figure 1), spindles, shafts, impellers, sleeves, bushes and pistons just to mention a few.

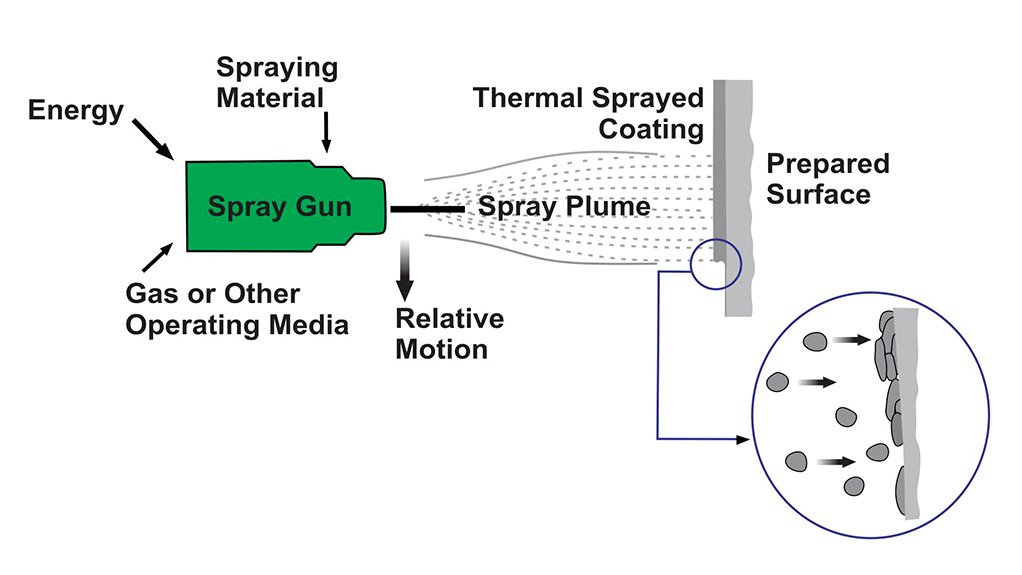

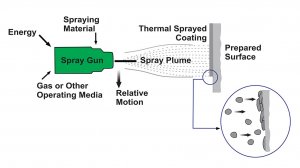

Thermal spraying comprises of various procedures, such as HVOF (High Velocity Oxy-Fuel), Flame- or Wire-Arc and Plasma. In these processes (figure 2), a fine powder – usually metallic, non- metallic powders such as ceramics is fed through a chamber by a gaseous carrier, which is then ignited. The powder is melted, and is then deposited onto the surface of the component being coated.

Thermal spray coatings for the turbomachinery industry includes thermal barrier coatings, wear control coatings, corrosion prevention coatings, high temperature environment coatings, oxidation resistant coatings and solid-particle erosion resistant coatings. Control technologies such as these coatings are essential to modern high performance, high quality industrial turbines.

The ability to ‘tailor design’ thermal spray powders and spray them to a designated hardness range using carefully monitored microstructural control has had a revolutionary impact on the service-life of turbomachinery.

Abradable thermal spray coatings, also known as clearance control/seal coatings, are successfully used in steam turbines and various other types of turbomachinery applications to reduce leakage gaps between stationary and rotating parts.

The abradable thermal spray coatings readily and sacrificially wear away when in contact with a rotating part; the resulting debris created by the abraded coating is soft (relative to the rotating surface) and fine enough to exit the system without causing erosion on other components of the engine. Abradable coatings can be applied by the flame (combustion) spray process or the plasma spray process.

The key performance criteria for abradable seal coating systems include:

• Rub compatibility against blades, knife fins or labyrinth seals under various conditions;

• Coating cohesive strength;

• Oxidation resistance at high temperatures;

• Corrosion resistance in aqueous or chemical fluid or gases;

• Resistance to corrosive attack at elevated temperatures;

• Sintering resistance at elevated temperatures;

• Thermal shock resistance, and;

• Resistance to solid particle erosion.

Applied to components such as labyrinth seals, impeller eyes, boss landings and balance drums, abradable coatings can be tailored to provide the required resistance to temperature (oxidation) and corrosion while adding clearance control for optimised efficiency.

Abradable thermal spray coatings are highly effective in reducing emissions and fuel consumption in turbomachinery. These coatings must satisfy two conflicting requirements; they must be abradable (i.e. porous), but equally mechanically stable in the harsh operating conditions of a gas turbine. Therefore, the ideal solution for gas turbines (figure 3) (and more recently steam turbines) is abradable coatings, which allow rotating compressor- or turbine blades to cut their own gas seal inside their casings, minimising losses and improving fuel efficiency.

Thermal barrier coatings can significantly increase turbine efficiency by allowing higher firing temperatures while reducing component thermal fatigue, warpage, oxidation and cracking. Wear control coatings can prolong the life of critical turbomachinery parts up to ten-fold, and corrosion prevention coatings can dramatically reduce corrosion damage while providing a smooth aerodynamic surface on compressor blades and stator assemblies.

Turbine components exposed to corrosion at high temperatures (+ 1,000 °F) not only degrade faster than at lower temperatures, but are also subjected to cracking due to thermal fatigue and cycling. High temperature-resistant coatings diffuse into the substrate, creating a nearly impenetrable surface which can reduce scaling and cracks due to thermal cycling. High temperature oxidation, a typical condition found in gas turbines, is mostly responsible for premature failure of ‘hot section’ components.

Oxidation resistant coatings impede oxygen penetration of the component surface while providing a sacrificial layer capable of protecting the part between overhauls. Solid particle erosion is most responsible for premature turbine failure and solid particle erosion coatings are specifically designed and tested for this environment and have proven effective in extending the life of critical steam turbine parts.

The full range of these coatings is available from Thermaspray’s well-equipped facilities in Olifantsfontein, Johannesburg, and joint venture company, Surcotec in Cape Town. Thermaspray’s large top-loading spray booth has the capacity to handle shafts of up to 5,500 mm in length and up to 6,000kg in weight.

“Thermaspray has enjoyed significant growth in the turbomachinery and rotating equipment market over the past six years and today these sectors make up almost a quarter of our business,” affirms Thermaspray’s Managing Director, Dr. Jan Lourens. “Thermaspray’s proven reputation of quality solutions and expertise has established strong business relationships with our customers who trust our precision-engineering capabilities and skillset to provide optimum solutions tailored to their individual requirements.”

Thermaspray, in a joint venture with Cape Town-based Surcotec, offers an extensive portfolio of engineering and thermal spray coating solutions that extend component lifecycles to assist OEM and end-user clients across southern Africa in reducing costs and increasing production.

The companies’ world-class quality wear- and corrosion-resistant thermal spray coatings, Plasma Transferred Arc (PTA) cladding and Polymer coatings (in partnership with Plasma Coatings USA and Diamant Metallplastic Germany) are augmented by a host of specialised allied services.

Captions to photographs

- Areas in a gas turbine that is coated with thermally sprayed abradable materials

- Thermal spray process

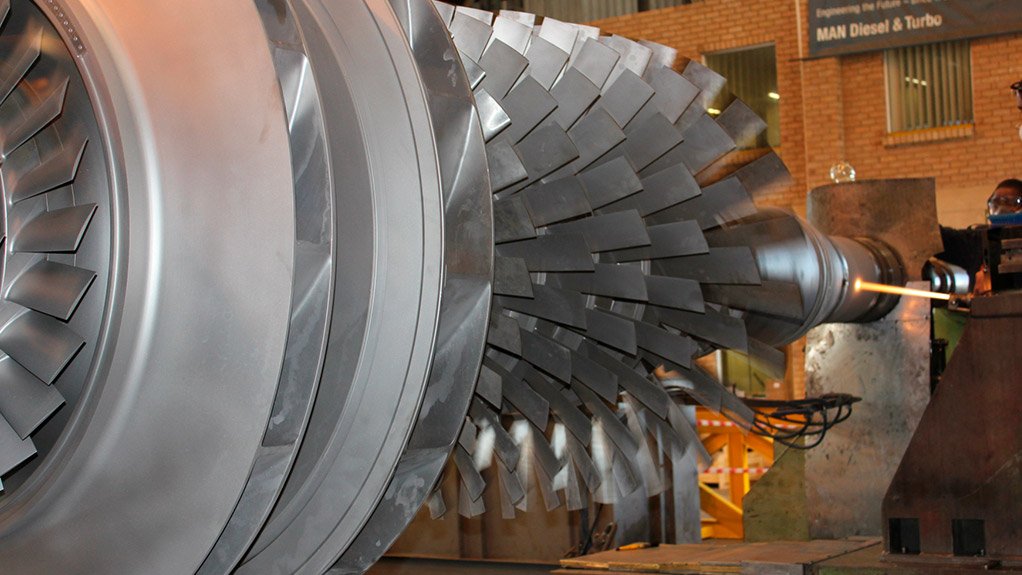

- Thermally sprayed coatings provide excellent protection against abrasion, corrosion, erosion, thermal degradation & high temperature oxidation on components eg compressor rotors.

Edited by: Creamer Media Reporter

EMAIL THIS ARTICLE SAVE THIS ARTICLE

ARTICLE ENQUIRY

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here