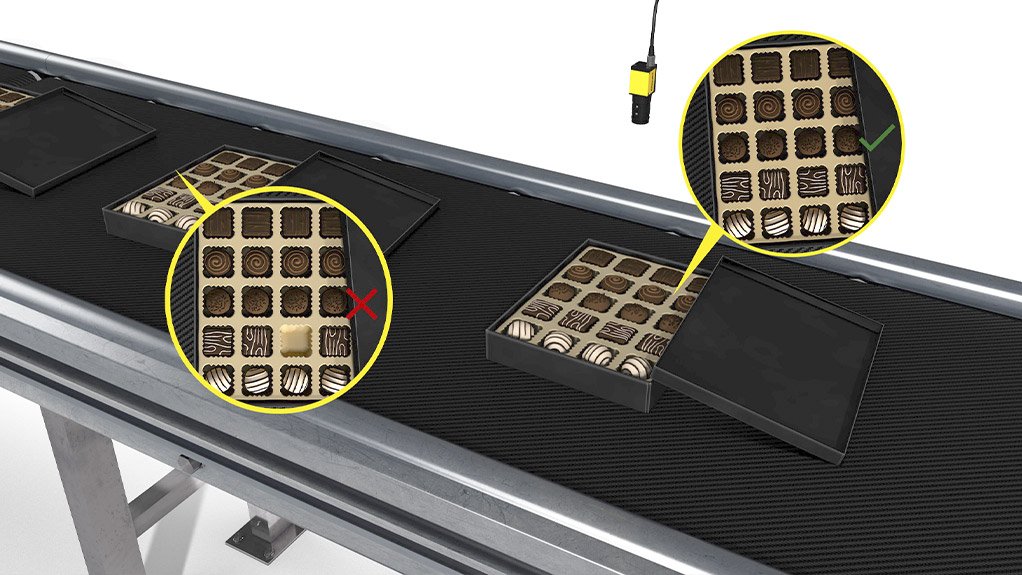

Embracing innovation in product-quality inspection, packaging inspection, assembly verification, allergen management, traceability, and food safety to minimise downtime are important for running a successful food and beverage operation. Delivering consistently high quality, safe products with fewer defects and less waste is essential, says industrial marking and coding equipment supplier Tracepack.

“Our machine vision systems and industrial barcode readers offer solutions to protect product quality and safety, ensure package integrity, manage allergens, and maintain traceability.”

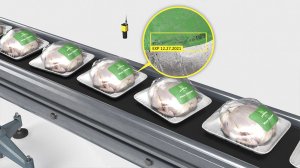

Date and lot codes, batch codes, and expiration dates are required on food and beverage products to identify when and where a product was made. These codes often combine 1D symbologies and plain text to encode the batch and manufacturing date information.

Optical character recognition (OCR) is used for reliable process control, helping manufacturers meet labelling requirements and ensure consumer safety. Quality inspections must verify that the codes are present and printed correctly to ensure traceability and more easily manage product recalls.

In-Sight vision systems with OCRMax technology detect the presence or absence of date and lot codes and verify that its chain of numbers and letters is correct. Deep learning solutions ensure that codes are accurately read and verified and that deformed, skewed, and poorly etched characters are decoded using OCR and optical character verification (OCV).

The pretrained, omni-font library identifies most text without additional programming or font training. The In-Sight 7000 series is a full-featured, powerful vision system that performs fast, accurate inspections of a wide range of parts across all industries. Its compact footprint easily fits into space-constrained production lines, and the unique, modular design is highly field-customisable to your application requirements, he boasts.

Along with the internal and external power/control lighting options, the In-Sight 7000 series also has a highly visible pass/fail light emitting device indicator light ring around the camera body, making it easy to see the inspection status no matter where the system is installed.

OCRMax is a font-trainable OCR and OCV tool that offers 99% accuracy on difficult-to-read characters. It prevents misreads, handles process variations, and provides easy font management with minimal training.

“OCRMax achieves unprecedented read rates for OCR and OCV applications even under the most challenging conditions while giving the customer the flexibility to optimise their system for speed, read rate, or a combination of both. This gives users the chance to optimise the OCR/OCV for millisecond character reads, 99.99% read rates, or anywhere in between.”

Unlike other OCR reading tools, OCRMax technology includes an auto-tune capability. With a few clicks, auto-tune dramatically decreases the time it takes to set up the device by acquiring a sample image, automatically training fonts, and adjusting the tool to its optimal segmentation parameters.

Packaging traceability is critically important for the overall safety of food and beverage products, which must be continuously monitored and occasionally recalled. It is also important for the security of products increasingly threatened by counterfeiting and theft.

Additionally, there are global regulations that must be met to provide a trail of information that follows each item through the supply chain. To ensure proper packaging traceability, food and beverage producers must quickly identify and locate products in the supply chain. To achieve this, many companies use two dimension barcodes, vision systems, and image-based barcode readers as key components in a simple yet robust traceability system.

Data Matrix codes have been adopted as the standard in many applications because they allow the storage of information such as manufacturer, product ID, lot number, expiry, and even a unique serial number. Track and trace solutions assure full compliance with food safety and traceability laws by capturing an image of a code at each scan point and storing its encoded data in a central database.

Cognex barcode readers reliably read one-dimension and two-dimension codes at read rates of 99.9% regardless of barcode quality or orientation. Image-based barcode readers have the speed and accuracy to ensure packages of all shapes and sizes are properly sorted, picked, stored or shipped and can be easily identified and located in the event of a product recall. In-Sight vision systems with OCRMax technology read alphanumeric date/lot codes and store the information in a central database to track and trace goods throughout the supply chain.

Industries increasingly turn to product security solutions to safeguard their products and meet industry requirements. “Our industrial barcode readers and machine vision systems address these concerns head-on by delivering the industry’s highest read rates, superior quality and assembly inspections, and supply chain protection. Our technology reads, inspects and authenticates products at the unit- and package level, easily exchanging security data with third-party software and hardware systems to verify products’ safe and accurate movement.

”

Edited by: Zandile Mavuso

Creamer Media Senior Deputy Editor: Features

EMAIL THIS ARTICLE SAVE THIS ARTICLE

ARTICLE ENQUIRY

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here