- Thermaspray (1.36 MB)

/ MEDIA STATEMENT / This content is not written by Creamer Media, but is a supplied media statement.

Thermaspray leads the South African market in the supply of thermal spray coatings that contribute to the extension of critical industrial component life cycles through protection against corrosion, erosion and other adverse conditions.

The use of thermal spray coatings to address an ever-increasing variety of surfacing needs, demands adherence to strict quality standards. Coating quality depends on spray process variables such as part temperature control, gun and substrate motion, spray pattern, deposition efficiency and deposition rate. Coating quality is further enhanced by post-coating operations which include finishing treatments such as grinding, polishing and densification treatments (fusion), testing and inspection.

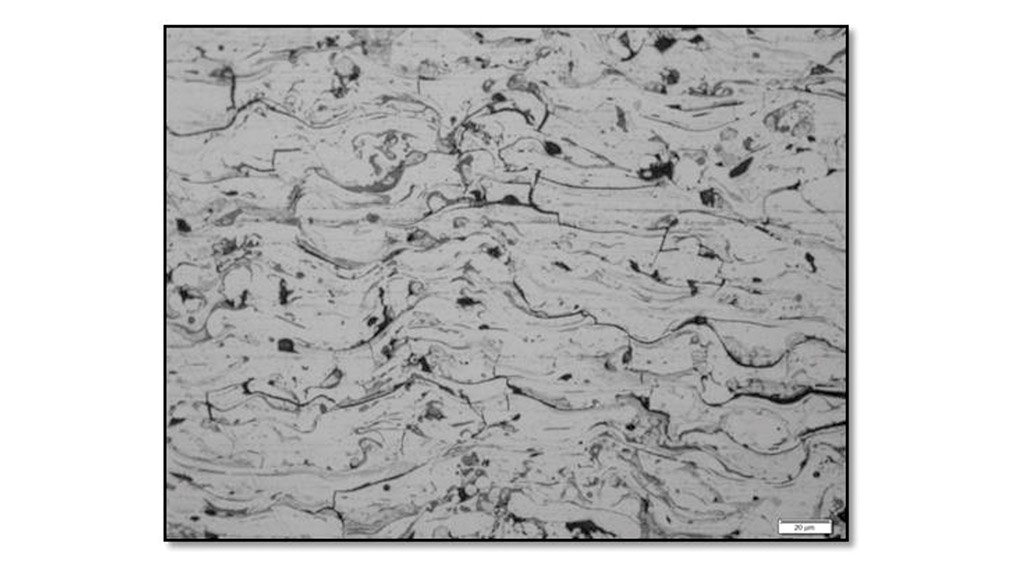

Good quality coatings (figure 1), contribute to extended component life, reduced costs and improved productivity. “Conversely, the application of bad quality coatings can lead to unplanned downtime, a drop in production and high repair costs,” warns Dr. Jan Lourens, Managing Director of Thermaspray.

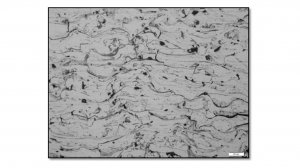

Dr. Lourens points out that poor quality coating can lead to delamination, cracking or even spalling of components during operation. “Coatings with lack of adhesion and cohesion or with foreign particles entrapped in the coating itself can cause flaking and peeling during in-service operations. Furthermore, coatings with oxide inclusions (figure 2) cause added coating hardness which in turn can lead to brittle coatings due to the fact that oxides fracture easily.”

Thermaspray boasts the only metallurgical laboratory in Southern Africa dedicated to the evaluation of thermal sprayed coatings. “We have developed techniques specifically tailored to evaluate the quality of thermally sprayed coatings in partnership with Oerlikon Metco (formerly Sulzer Metco), adds Dr. Lourens.

Adherence to the strictest standards in coating processes and quality evaluation to ensure coatings of the highest standards and quality available on the market positions Thermaspray at the forefront of the thermal spray coating industry in South Africa.

Thermaspray, in a joint venture with Cape Town-based Surcotec, offers an extensive portfolio of engineering and thermal spray coating solutions that extend component life cycles to assist OEM and end-user clients across southern Africa in reducing costs and increasing production. The companies’ world-class quality wear- and corrosion-resistant thermal spray coatings, Plasma Transferred Arc (PTA) cladding and Polymer coatings (in partnership with Plasma Coatings USA and Diamant Metalplastic Germany) are augmented by a host of specialised allied services.

Edited by: Creamer Media Reporter

EMAIL THIS ARTICLE SAVE THIS ARTICLE

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here