Maintenance of plant and equipment very often goes hand-in-hand with the need for refurbishment of worn components owing to damage caused by wear. Higher levels of maintenance often reduce the need for refurbishment, but if the need arises, experts in wear protection Welding Alloys South Africa has what it takes to keep plant and equipment running for longer.

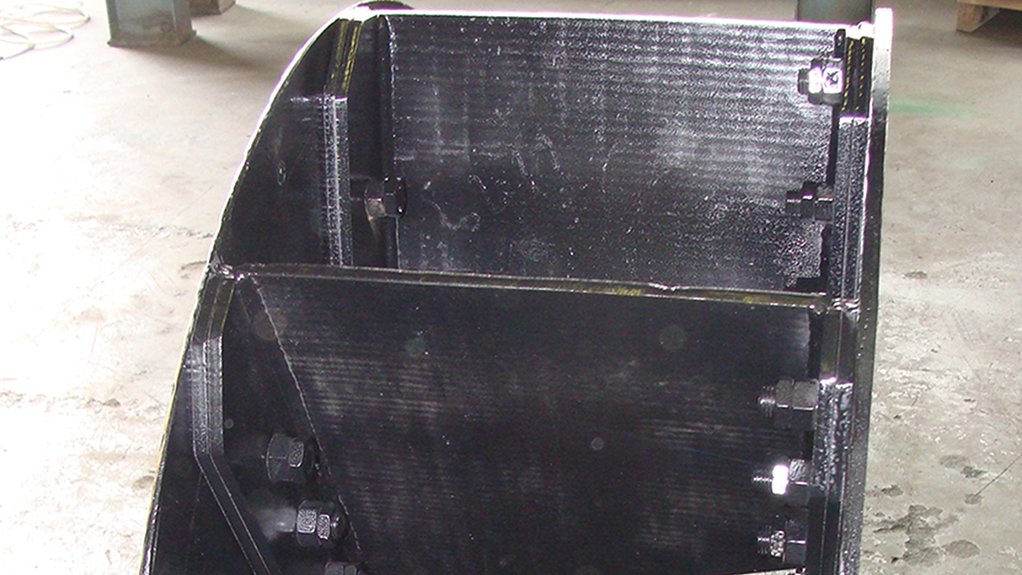

Its technical ability and vast range of hardfacing, cladding, build-up and repair consumables allow many customers to salvage and repair worn equipment, often to higher standards than the original item, instead of having to replace them at a much higher cost and often extensive lead times.

Examples of these refurbished parts are mill grinding components, crusher hammers, sugar cane rollers and steel mill components, allowing them to be used very successfully way beyond their initial design life.

The company’s solutions for wear protection in transportation systems, chemical environments, storage systems, truck trays and loading equipment have assisted many a customer to decrease cost, increase productivity, save time and keep equipment running for longer at peak performance.

The Welding Alloys philosophy of providing wear solutions instead of mere products, distinguishes the company from the competition in that it works with its customers to derive the best possible solution to the problem.

“Our technical spark solves your industrial challenges,” says Welding Alloys.

Edited by: Creamer Media Reporter

EMAIL THIS ARTICLE SAVE THIS ARTICLE

ARTICLE ENQUIRY

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here