While competitive pricing may attract attention, it is the combination of robust warranties and strong aftermarket support that truly defines operational efficiency, longevity and total cost of ownership of equipment, says crushing and screening equipment supplier Pilot Crushtec sales and marketing director Francois Marais.

Considering that high-stakes industries, such as mining, quarrying and construction, face many challenges and myriad considerations, a robust warranty can be key in defining the life span of equipment, consequently shaping its overall operational efficiency and cost-effectiveness.

Robust warranties play a “pivotal role” in risk mitigation, absorbing the costs associated with “unexpected technical failures or manufacturing defects”.

Marais adds that warranties provide predictability in financial planning, as they allow for efficient budget management and effective contingency planning.

A warranty is also testament to a manufacturer’s confidence in its product, indicating that the product has met rigorous quality-control standards and that the manufacturer is willing to stand by its reliability, he states.

For example, Finnish industrial company Metso – the equipment of which Pilot Crushtec is the Southern African regional distributor – extends a five-year warranty to its tracked and fixed range of material crushers, fixed crushers and screens.

Machinery, such as the Lokotrack mobile series and the C-Series heavy-duty jaw crushers, are purpose-built for demanding mining and hard-rock applications, consequently falling under the umbrella of a more comprehensive five-year/10 000-hours warranty, whichever occurs first.

Robust aftermarket support is also vital for equipment longevity and operational efficiency, emphasises Marais.

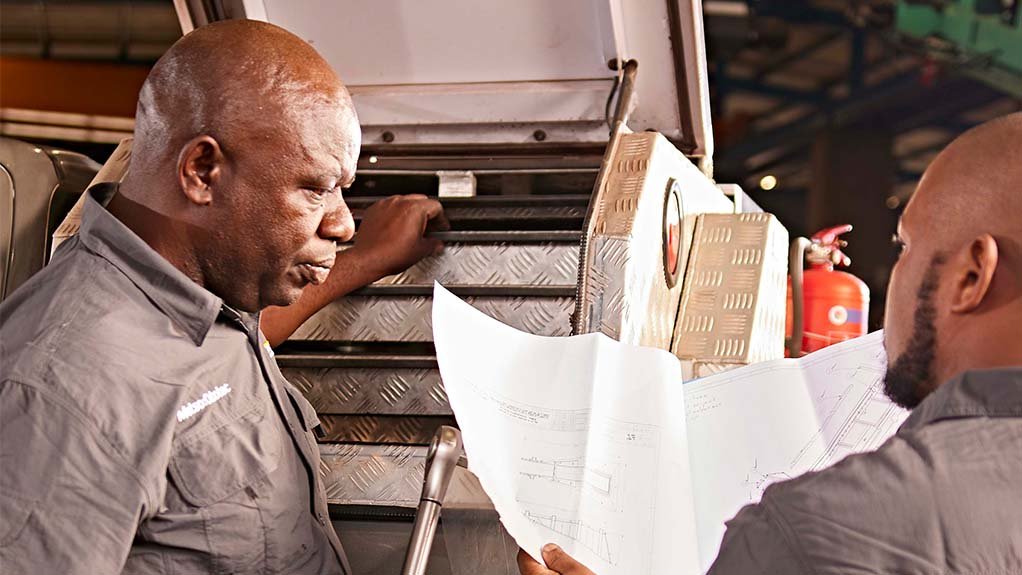

Pilot Crushtec’s comprehensive support in this regard encompasses fully equipped repair and maintenance facilities, access to skilled technical experts, readily available spare parts and highly capable field service teams.

“Aftermarket support forms the backbone of equipment sales and helps customers to minimise operational downtime. We provide solutions to complex issues, and ensure optimal equipment performance throughout the machine’s lifespan,” Marais notes.

However, when investing in crushing and screening equipment, he urges businesses to evaluate the robustness of warranty policies and the strength of aftermarket support, as these factors directly impact on operational efficiency, cost management, as well as the overall performance, reliability and longevity of equipment.

“Manufacturers understand the profound impact of warranties and aftermarket support on customer satisfaction and equipment performance. Quality-conscious manufacturers like Metso understand that a robust warranty signifies their commitment to the product’s durability and performance,” he explains.

Having faith in their products enables manufacturers to build a strong relationship of trust, and a partnership with their customers.

“This connection goes beyond mere transactions; it represents a commitment to customer success and operational efficiency. Warranty claims become opportunities to demonstrate reliability and integrity, fostering lasting relationships that extend far beyond the initial purchase,” he adds.

As such, when evaluating warranty options, Marais suggests that customers should delve beyond the terms and conditions and ask pertinent operational questions, as understanding the claims procedure, support mechanisms and turnaround times is crucial.

Manufacturers with well-established, transparent procedures are better equipped to handle warranty claims efficiently, enabling customers to focus on getting their operations back on track, he concludes.

Edited by: Donna Slater

Features Deputy Editor and Chief Photographer

EMAIL THIS ARTICLE SAVE THIS ARTICLE

ARTICLE ENQUIRY

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here