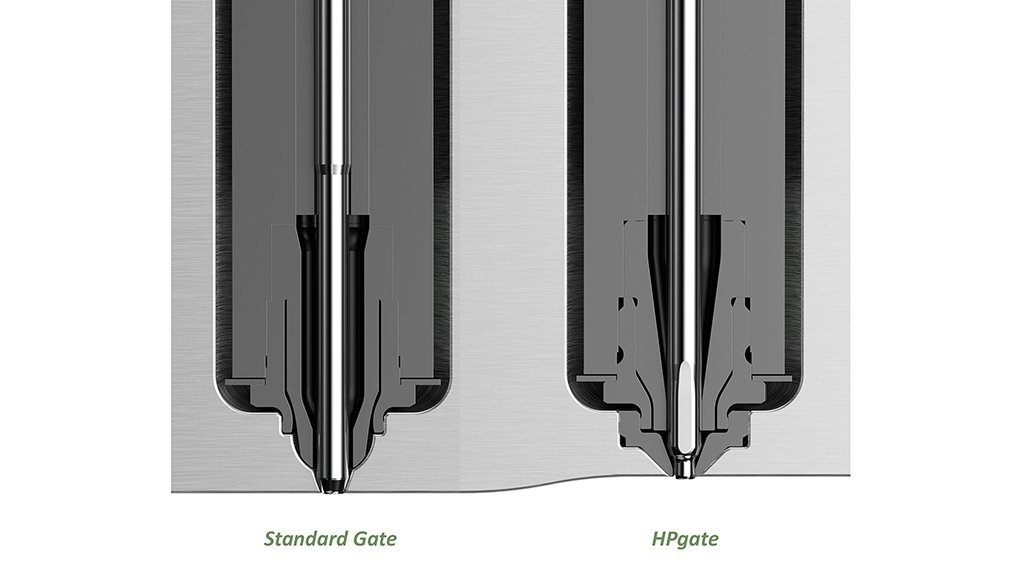

With its HPgate, Italian hot runner specialist HRSflow presents a new, quality-enhancing, cost-saving valve gate solution for the manufacture of high-quality parts without flash.

Compared with the conventional versions, the gate is machined on a hardened metal insert produced by HRSflow.

The insert is simply screwed into the mould, which is easy to replace in the event of wear.

This solution saves the mouldmaker the time- consuming and complex machining of the standard cylindrical gate.

Equally beneficial for the mouldmaker is the outstanding hardness of the insert; a less hard steel could also be chosen for the mould plates, says HRSflow.

Another advantage comes from the special needle geometry in which the conical contact surface allows better thermal control of the needle temperature, while the precisely aligned cylindrical needle closure assumes the task of sealing, explains HRSflow.

“An even higher gate quality can be obtained by combining the HPgate technology with HRSflow’s FLEXflow technology. Here, the needle position can be precisely controlled, thereby reducing the influence of the process conditions even further,” HRSflow says.

Contact: Erica Gaggiato

Company: HRSflow

Tel: +39 0422 750 111

Email: erica.gaggiato@inglass.it

EMAIL THIS ARTICLE SAVE THIS ARTICLE

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here