Industrial equipment supplier BMG reports that the reduced life of V-belts operating in the heating, ventilation and air-conditioning (HVAC) sector is a major concern to the industry, despite users implementing rigorous system inspection programmes in an effort to counter this trend.

BMG specialists recommend that replacing conventional rubber V-belts used on air-handling units (AHUs) with Fenner high-performance composite (HPC) V-belts, is a dependable solution that offers many benefits, including higher drive efficiency, greater comfort, reduced downtime and extended service life.

“BMG’s Fenner HPC V-belts have been proven to maintain 100% of their belt life at 80 °C, in comparison with only 25% belt life from a rubber belt at the same temperature,” explains BMG Power Transmission product manager Westnar van der Westhuizen.

He notes that when the internal operating temperature of a rubber V-belt surpasses 30 °C, adhesion between the rubber and reinforcing cords starts to break down, with delamination and flex fatigue occurring as a result. This leads to the rubber compound deteriorating, forming cracks and leading to premature belt failure.

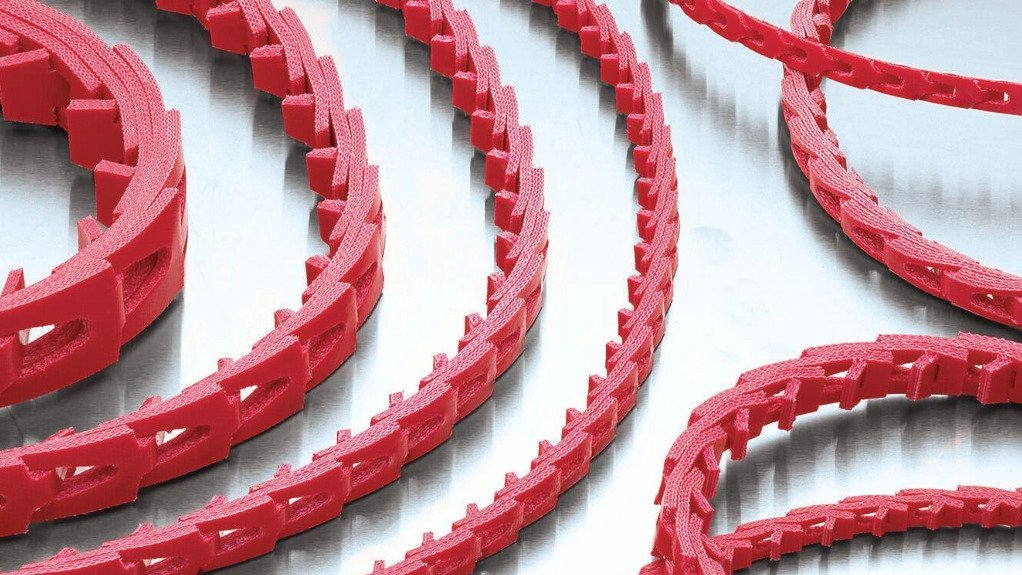

Van der Westhuizen states that BMG’s range of Fenner HPC V-belts includes the PowerTwist Plus and NuTLink V-belts for classical section drives, and SuperTLink V-belts for applications using metric wedge SP-rated belts.

While simple in concept, these composite V-belts deliver improved performance, solving many of the field problems associated with conventional rubber V-belts.

“This range is manufactured from custom reinforced polyurethane elastomers, with multiple plies of polyester fabric, that offer excellent resistance to high operating temperatures,” he says.

When compared with a solid construction rubber V-belt, the effective link design of BMG’s range of Fenner HPC V-belts results in belt constructions limiting flex induced heat build-up and ensures a greater surface area that dissipates any heat generated more effectively.

“Another important benefit of upgrading from rubber to HPC V-belts, is reduced belt installation time,” says Van der Westhuizen.

Further BMG’s range of Fenner HPC V-belts makes it easy for users to make a V-belt to the required size by hand and roll it onto an AHU drive, just like a bicycle chain, with no tools required.

PowerTwist Plus drive belts, which do not require retensioning after the initial run-in, combine extremely high-strength with low-stretch capabilities, and have the same power ratings as conventional V-belts.

The elasticity of woven polyurethane fabric enables these belts to be stretched over a pulley drive without any damage.

This series is designed for decreased drive vibration, resulting in increased bearing life.

Fenner PowerTwist Plus belts are easily made up to the required length in seconds and there is no longer the need to move or dismantle any drive component, making it easy for users to always hold the correct inventory.

Fenner NuTLink V-belts, with a quick connect T-Link design, are suitable for heavier, shock-loaded applications and reciprocating engine-powered drives.

SuperTLink SP wedge V-belts also have a quick connect T-Link design, with suitability to replace metric V-belts of SPZ, SPA, SPB and SPC cross sections.

Van der Westhuizen concludes that other Fenner products available from BMG include synchronous transmission belts, pulleys and accessories, as well as shaft fixings, chain drives and couplings, as well as Fenner shaft-mounted speed reducers.

Edited by: Donna Slater

Features Deputy Editor and Chief Photographer

EMAIL THIS ARTICLE SAVE THIS ARTICLE

ARTICLE ENQUIRY

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here