Engineering solutions supplier Bearing Man Group (BMG) GM Carlos Beukes states that Timken Quick-Flex couplings, along with Vulkan GBM heavy industrial couplings, are designed for efficient performance in a diverse range of applications to transmit torque from a driving shaft to a driven shaft while accommodating shaft misalignment within the drive.

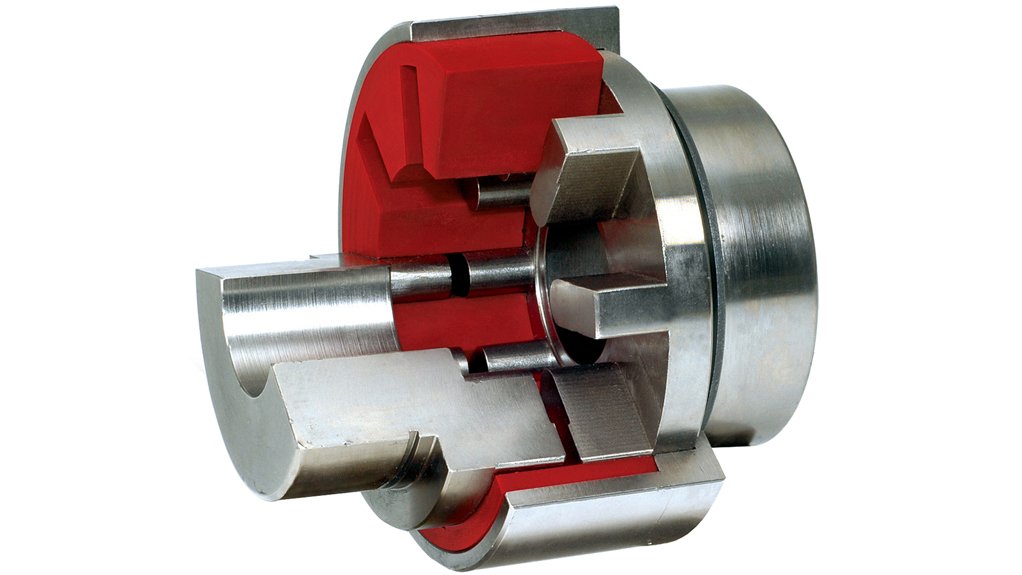

The Timken Quick-Flex couplings are made up of two steel coupling hubs which are attached to the drive and the driven shaft. An element made of urethane wraps around the two hubs and provides a simple, yet effective, drive mechanism that negates the need for spare parts, barring a standby element that can be changed quickly when necessary.

The Timken Quick-Flex couplings are aided by a range of inserts which are resistant to chemicals and manufactured from varying grades of urethane to ensure that couplings can handle the demands of the different industries and applications.

The red inserts are suitable for speed applications with high levels of vibration, the stiffer blue inserts are designed for higher torque applications and the black insert is capable of withstanding extremely high torque requirements, replacing grid and gear couplings.

Another benefit provided by the couplings, which is not apparent on conventional units, is direct replacement with virtually all comparable sized couplings. The Timken Quick-Flex couplings do not require lubricants and are easy for users to install and maintain.

Owing to the high torque capacity of this range, the selected Quick-Flex solution is often smaller than the replaced coupling, leading to a major weight reduction on the drive as well as stress reduction on other components.

Three different elements are available in each of the different sizes of coupling. Each coupling has a different torque rating. The flexibility of this design makes the range suitable for many applications, from high speed/low torque/excessive vibration drives, to a low speed/high torque application.

Important features include excellent balance, allowing for high-speed applications of up to 12 000 rpm, angular misalignment up to 2° accepted by the couplings and parallel shaft displacement up to 7.92 mm.

Once the two coupling hubs, the insert and cover have been installed and aligned for the first time, the coupling hubs do not need to be moved again for the life of the equipment. Unlike standard jaw-type or gear couplings, no metal-to-metal contact occurs between the hubs.

This prevents any possible damage to the ironware during an element failure. The urethane insert can easily be changed without moving the hubs or shafts and no realignment of components is necessary.

The compact couplings allow for compensating axial, radial and angular misalignments and also protect the drivetrain from shock loads.

The Quick-Flex solutions range is designed to be modular, enabling the integration of brake discs, pulleys, shear devices and spacer shafts within the coupling. The possibility for radial removability of the coupling elements without the need to move the connected machinery has been introduced. No lubrication is required during assembly or disassembly.

These torsional flexible couplings have a maximum torque of 1 288 800 Nm and shaft diameters of up to 600 mm. This range is equipped with elastic elements that are specially designed to work in compression, allowing for maximum torque transfer and heat dissipation, which allow for greater product longevity.

Vulkan Flexomax GBN couplings, available in 16 sizes, with nine designs, have customisable options to meet the requirements of restricted applications.

Enhanced by advanced technical and design support across all functional disciplines, BMG is committed to providing a 24-hour customer process support for production efficiency and reliability- centred maintenance.

Edited by: Zandile Mavuso

Creamer Media Senior Deputy Editor: Features

EMAIL THIS ARTICLE SAVE THIS ARTICLE

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here