Pretoria-based industrial technology and solutions provider RTS Africa Technologies (RTS) has recently announced the increased availability of its Gen5 System, developed specifically for transformer oil dissolved gas analysis (DGA) for distribution transformer monitoring.

A large percentage of transformer failures are caused by ignition and explosion of gasses. The detection and DGA should be a primary maintenance routine for transformer operators.

Traditionally, this is carried out by technicians that visit transformers on a regular basis and carry out tests to identify the presence of gasses dissolved in the transformer oil. This is an expensive and frequently unreliable procedure.

Owing to the decreased availability of personnel taking DGA samples – a situation aggravated by the Covid-19 pandemic – many utilities now choose real-time monitoring of transformer oil dissolved gasses, for which the Gen5 System becomes the most suitable system to use.

The Gen5 System is a product of US-based company H2scan of which RTS is an agent in South Africa.

H2scan has increased production capacity of the Gen5 System to accommodate the increased demand globally for the Gen5 System as utilities begin implementing real-time measurement on lower cost assets.

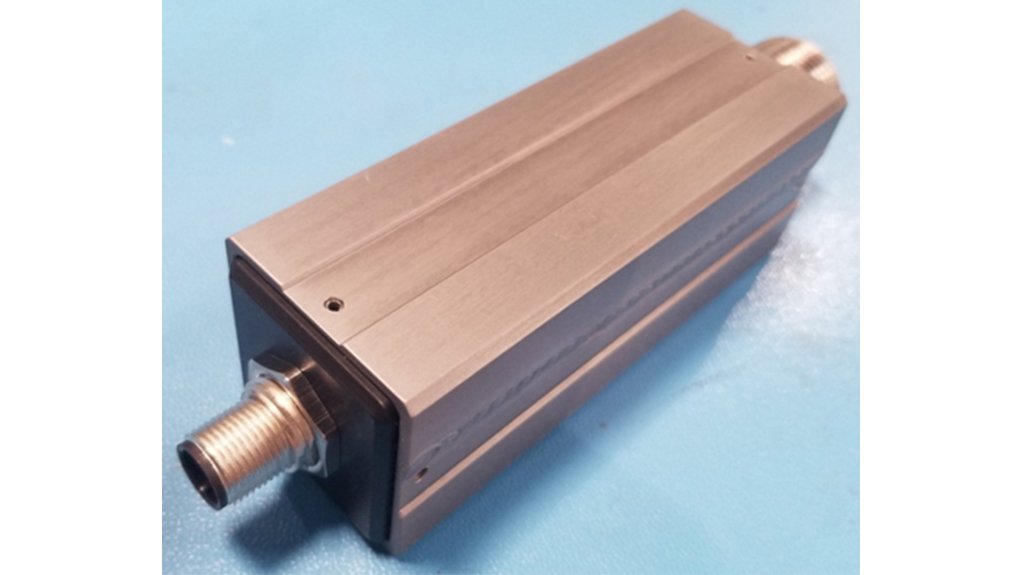

The Gen5 System is a unique hydrogen sensor package based on H2scan’s application specific integrated circuit (ASIC) technology that makes it a compact and cost-effective instrument that is ideal for use on distribution transformers.

The Gen5 System enables real-time hydrogen monitoring for reduced risk of explosion and catastrophic failure and is ideal for use in distribution transformer applications, including those located in populated areas such as suburbs, under streets and in industrial sites.

The ASIC-based system delivers high accuracy sensing at a dramatically reduced price while still being the same reliable hydrogen sensing element that has been delivered globally since 2012. Over 15 000 hydrogen sensor systems have been installed with no replacements or recalibrations.

The sensor system works with oil immersed transformers and offers real-time, or step-change monitoring to report hydrogen levels as they fluctuate. Its high accuracy sensor head can track hydrogen levels in the transformer oil from 25 ppm to 5 000 ppm at oil temperatures up to 150 °C. The real-time monitoring is ideal for smaller transformers where power overloads can cause higher temperatures which drive up hydrogen levels more quickly.

The Gen5 System incorporates H2scan’s patented autocalibration technology, requiring no maintenance or recalibration for up to 10 years. Total install or retrofit time of the Gen5 System is less than one hour. The instrument is IP68 rated and can withstand 14 days of submersion in water to a depth of up to 10 m, making it ideal for underground vault transformers.

With its high 150 ºC temperature and 25 ppm to 5 000 ppm hydrogen concentration, this instrument is ideal for monitoring wind farm and solar farm transformers. Additionally, the Gen5 System has found application with a large provider of the traction transformers that are used for powering electrical locomotives. Owing to the locomotives powering heavy freight loads, reliability and safety are critical in traction transformers.

In the midst of the Covid-19 pandemic that is impacting every industry globally, the Gen5 System is a game changer for utilities wanting to eliminate manual sampling and substation visits by its maintenance crew in order to obtain real-time measurements. Given its lower cost that is significantly below other systems, the Gen5 System is ideal for utilities to retrofit onto their entire transformer population.

Edited by: Zandile Mavuso

Creamer Media Senior Deputy Editor: Features

EMAIL THIS ARTICLE SAVE THIS ARTICLE

ARTICLE ENQUIRY

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here