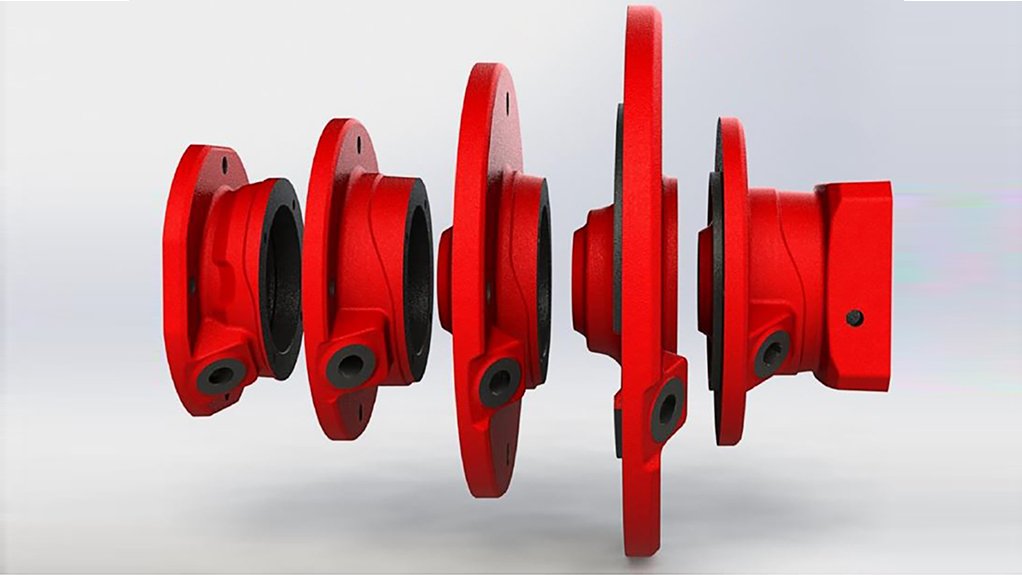

SEW-EURODRIVE has launched its AMS adapter with added features, such as a more compact design, longer bearing life and a drain hole for vertical installations.

According to SEW-EURODRIVE head of engineering Andreas Meid, the company’s adapter has played a valuable role in allowing its IEC motor to be integrated with a SEW-EURODRIVE gearbox, and the new AMS adapter has been upgraded with more refinements to benefit the end-user.

“The first improvement we introduced with this AMS adapter is to make it more compact,” says Meid. “Its smaller footprint allows users to install it more easily in areas where space is constrained; in fact, we have been able to reduce its dimensions by up to a full 25%.”

The bearing selection in the AMS adapter has also been reviewed to optimise the bearing life relative to the operating temperatures.

“We have also considered the specific requirements of vertical installations, and included a drain hole to ensure that any liquid can easily exit the adapter,” he says. “The flinger transports the liquid to the through bores in the intermediate flange, where it can drain out.”

He explains that this ensures that liquid will not enter the bearings and gears, enabling components to achieve a longer operating life.

“The range of frame sizes also makes it versatile across many industry applications; we offer 12 sizes from IEC 71 to IEC 280,”says SEW-EURODRIVE head of exports Marcio Sicchiero.

He notes that this package comes already assembled, reducing the time and cost and operational risk of trying to assemble components on site. Among the most common applications of the AMS adapter, motor and gearbox are agitation and mixing activities in the mining and water sectors.

EMAIL THIS ARTICLE SAVE THIS ARTICLE

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here