Press brakes are vital pieces of equipment in the metal industry and are recognised as the best machinery for bending plate and sheet metals to precise angles and dimensions, helping to deliver custom parts to a range of industries including aviation, automotive, agricultural, energy and transportation.

Most press brakes are operated by means of programmable system inputs but individual pieces of metal are still aligned and placed manually. This process is set to change, however, through the integration of robotics and press brakes.

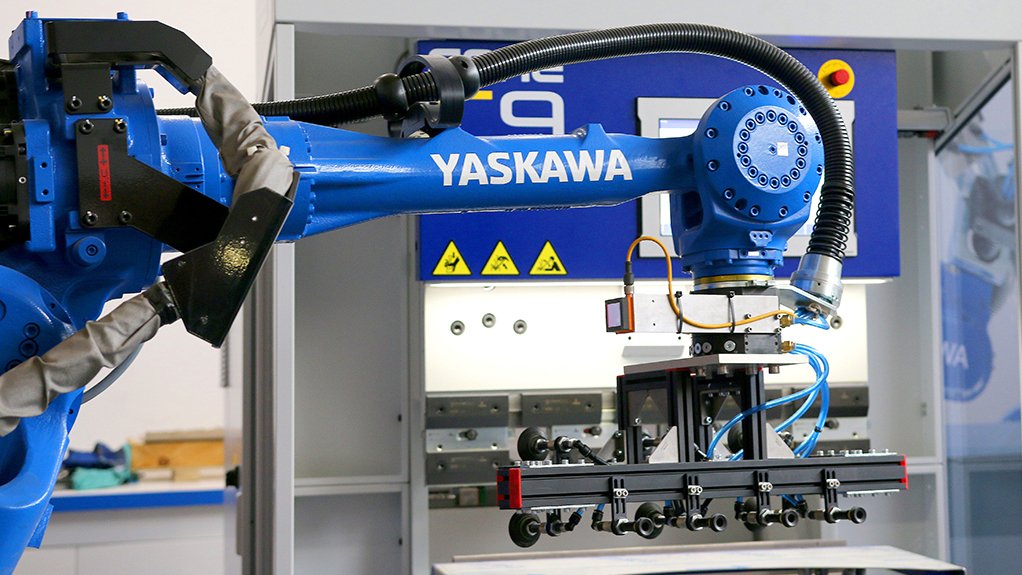

Yaskawa Finland has previously collaborated with European press brake manufacturer Coastone to develop a robotics and press brake integration solution and the company is now undertaking a similar collaboration with Metal Chip Machinery, the South African distributers of Coastone.

The opportunity to supply a customer in South Africa with a robotic press brake solution arose when an existing client requested a solution to speed up their manufacturing process. “The task was to create a solution for a company that uses sheet metal bending to manufacture electrical boxes, which are designed for domestic, factory and industrial use,” explained Metal Chip owner Malcom Moriarty.

Yaskawa Southern Africa sales engineer John Mostert reveals the thought process behind the request: “The reason Yaskawa was approached, is that right now it is a very manual process. The customer’s press brake would require an operator that would have to be in front of the machine all the time, but with a robot we are able to automate the process therefore achieving higher volumes of production,”

The press brake integrated with a Yaskawa robot aims to provide cost-effective automation solutions for customers and Mostert highlights the opportunity for local fabricators to ramp up production and challenge international competition.

“The robot is fitted with a vacuum gripper device with suction cups that will pick up the various pieces of sheet metal and present them to the press brake for bending. The gripper is designed to easily handle the material despite its change in form after bending shape multiple times,” describes Mostert. Yaskawa provides customers with training for the robot operators and both the press brake and robot are programmed and calibrated to specifications.

All Coastone press brakes are now available with the option of an integrated Yaskawa robot interface, allowing for seamless plug and play connection.

EMAIL THIS ARTICLE SAVE THIS ARTICLE

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here