Drive engineering specialist SEW-Eurodrive has successfully filled an order for the delivery of 20 drive systems and a gear motor from its X series range for the newly constructed Liqhobong diamond mine, in Lesotho.

The drives and gear motor were installed for a conveyor application, with SEW-Eurodrive recently supplying three additional drive systems for the Liqhobong tailings project.

Aim-listed diamond mining and exploration company Firestone Diamonds describes its Liqhobong mine as a robust project, with more than 11-million carats in reserve, noting that the total openpit resource comprises more than 17-million carats down to 393 m.

As of October 6, all major construction activities had been completed at the company’s 75%-owned mine, which is 25% co-owned by the government of the Kingdom of Lesotho.

Firestone reported at the time that it expected to complete the commissioning of the mine’s recovery plant and sort house in anticipation of first diamond recoveries later that month.

Mining activities have started, and the commissioning of the processing plant was in its final stages as of October 6. According to Firestone, the new plant is designed with a capacity of 500 t/h, comprising a twin stream of 250 t, to yield one-million carats a year over a 15-year life-of-mine.

SEW-Eurodrive says Liqhobong is subjec to a series of extensive work streams to further derisk the project. The company has worked to ensure that the best gearbox is selected for the conveyor application, meeting the required bearing life and the thermal capacity based on the site’s operating environment.

SEW-Eurodrive head of projects Rudi Swanepoel states that working on the Liqhobong diamond mine is one of SEW-Eurodrive’s flagship projects, as all the conveyor systems have been fitted with SEW-Eurodrive products and the company is proud to have supplied the mine with its products.

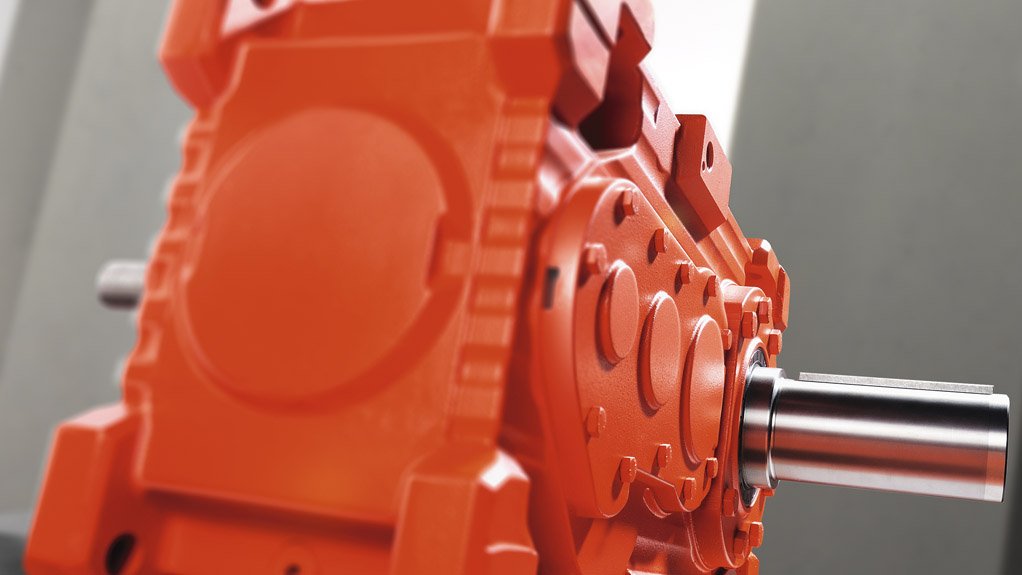

The X series horizontal process drive system from SEW-Eurodrive has a torque range of 6.8 kNm to 475 kNm. The product includes a large number of predefined accessories that offer a high degree of flexibility to adapt to a range of applications using minimal components while offering maximum availability.

Characteristics of the X series drive system include standardised helical and bevel units for all agitating processes, an invertible gear unit housing, modular technology and a number of variants, owing to predefined options.

The system offers a short turnaround time on delivery for standard versions and spare parts and an extremely robust design, as well as reduced costs and weight, owing to high power density, effective cooling systems, Atmosphères Explosibles certification and worldwide service delivery.

The X series gear motor design features an independent industrial gear unit platform, helical and bevel-helical gear units, a single-piece and split-gear unit housing, an invertible gear-unit housing, universal mounting positions and distinctive modular technology.

The company offers customers a complete customisable solution, says Swanepoel, adding that it works closely with clients to provide the right solution with particular specifications, and can assist with project planning to commissioning.

SEW-Eurodrive head of exports Marcio Sicchiero points out that the company is dedicated to supporting clients in keeping their total cost of ownership as low as possible, regardless of their requirements, be it technical calculations, specific documentation (such as quality certificates or project- specific operating instructions), condition monitoring or on-site services.

He explains that SEW-Eurodrive has a research and development (R&D) team in Germany consisting of more than 300 engineers. South Africa has access to Germany’s R&D, which assists in facilitating faster turnaround times on projects.

However, after-sales services are a significant focus for the company, which has been proactive in the industry in terms of helping the mining industry mitigate the impact of challenging market conditions and to remain sustainable, Sicchiero adds.

“Over and above the [X series drives and gear motors], we are currently supplying the market with a competitive IE3 premium efficiency motor. We are currently supplying these motors into the agitator, mixer and aeration industry and we are also putting a lot of emphasis on the materials handling industry,” concludes Swanepoel.

Edited by: Tracy Hancock

Creamer Media Contributing Editor

EMAIL THIS ARTICLE SAVE THIS ARTICLE

ARTICLE ENQUIRY

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here