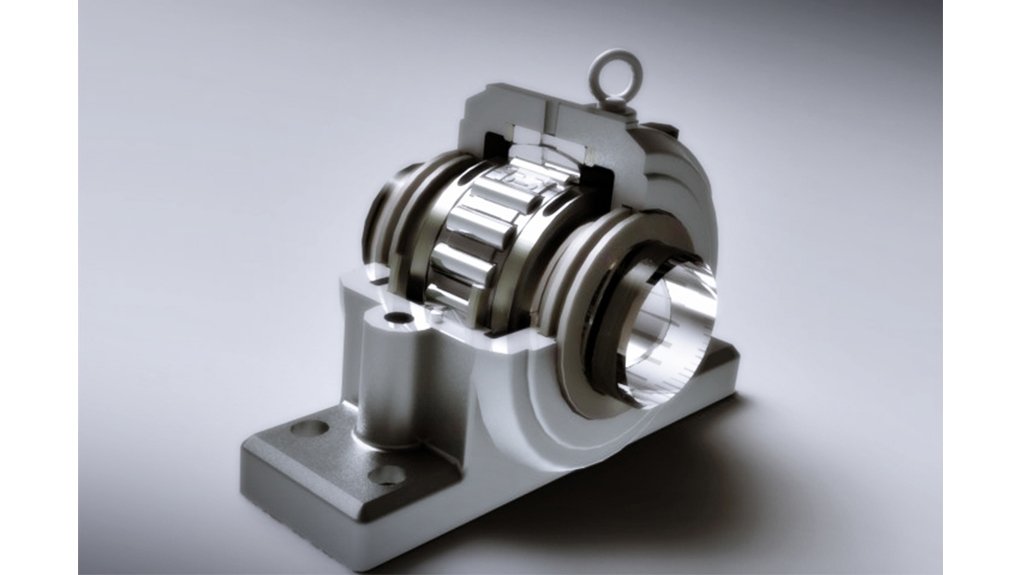

Industrial equipment supplier BMG specialists recommend HKT split cylindrical roller bearings for dependable use in extreme conditions, including applications above ground, underground and in underwater environments.

BMG’s high-performance HKT split cylindrical roller bearings – which have been developed to operate efficiently in demanding environments – are incorporated into conveyors, fans, cooling beds, continuous casters, stacker reclaimers and motors and generators.

According to BMG, split bearings offer improved performance in difficult applications, particularly when the replacement of standard mounted bearings involves the removal of machinery and components, like large gearboxes and couplings.

Other advantages of split bearings include lower operational costs and reduced downtime for moving equipment or changing bearings.

“HKT split roller bearings operate efficiently in arduous conditions where dust, moisture, chemicals, heat and dirt would normally affect performance. Split bearings also cope with high radial loads, have greater speed capabilities, and operate efficiently at elevated temperatures,” explains BMG bearing division business development manager and bearing specialist Coenie Van Deventer.

He adds that HKT split cylindrical roller bearings have a robust clamp ring design that offers cage alignment and simplifies maintenance procedures.

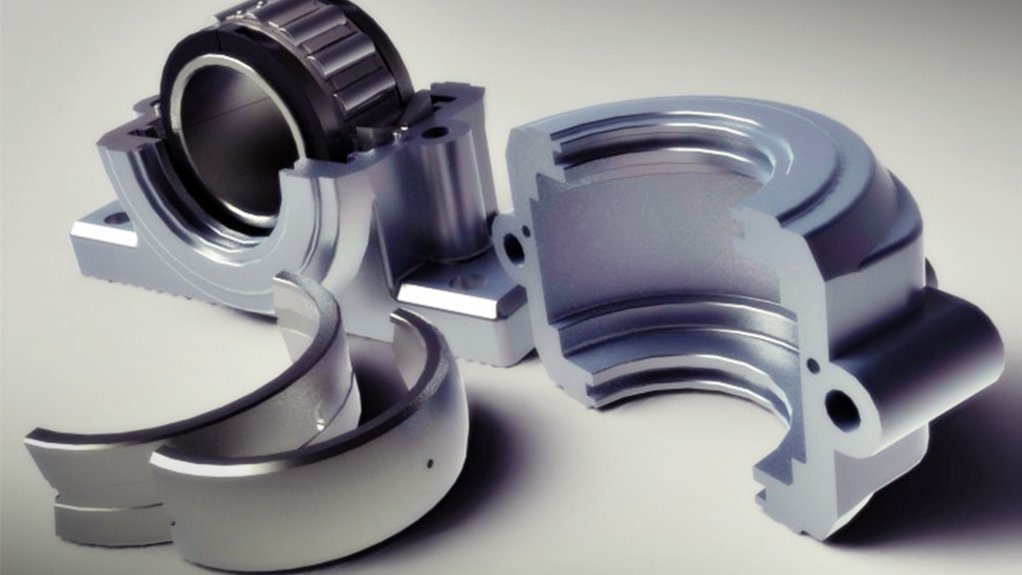

These bearing units can be disassembled into smaller components, easing the tasks of lifting and handling, and ensuring effortless mounting or replacement, even in cramped and inaccessible conditions.

Clearances of these units are preset, so there is no requirement for on-site adjustments or specialised fitting tools.

BMG supplies various kinds and sizes of HKT cylindrical bearings, including split cylindrical roller bearings with a housing and support, and split roller bearings with a standard plummer block – the SPL series.

The range consists of the 100 series for light applications, the 200 series for heavy industries and the 300 and 400 series for extra heavy and high-speed applications.

Typical applications for this range are in steel, mining, marine and conventional power, and renewable energy. Split roller bearings are also suitable for use in industries including sugar, agriculture, cement and building materials.

The BMG team works closely with its customers to identify exact mechanical component requirements and ensures the correct bearing selection for every application. BMG advises on cost-efficient solutions for the optimum productivity of machinery, extended service life of the system and minimal maintenance requirements.

The team is committed to offering workable solutions to real problems beyond the scope of traditional customer/supplier relationships, to help every customer improve efficiencies and profitability.

BMG introduces the latest global technologies, trends, and products to the local market to meet exact demand.

Through its critical focus on entire production processes, the company’s extensive range of quality branded components, engineering solutions and technical services optimise productivity and enhance process plant operating reliability.

Edited by: Zandile Mavuso

Creamer Media Senior Deputy Editor: Features

EMAIL THIS ARTICLE SAVE THIS ARTICLE

ARTICLE ENQUIRY

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here