New universal white light-emitting diode (LED) technology is set to change the way original-equipment manufacturers (OEMs) design lighting functions.

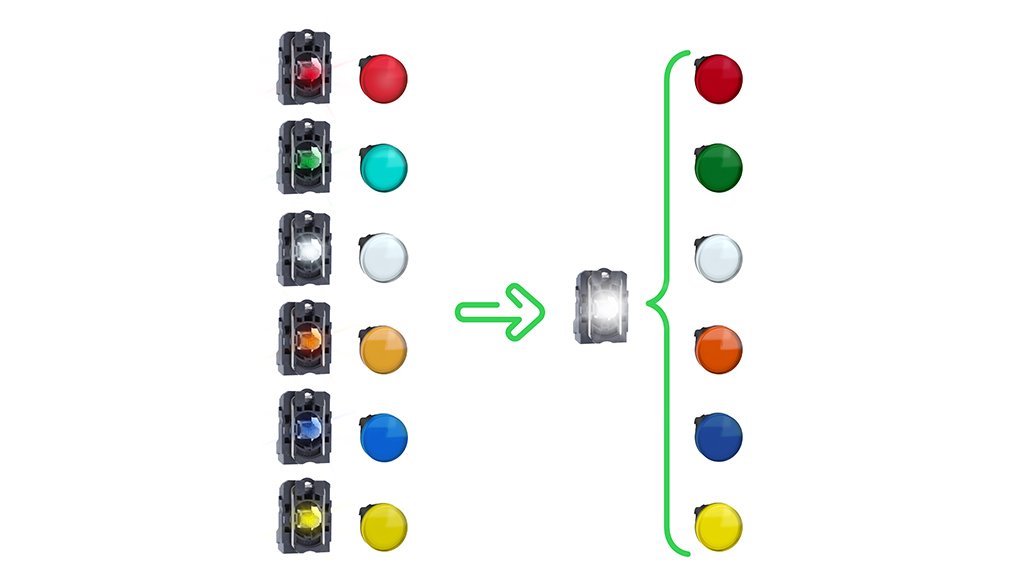

This is according to Schneider Electric, that recently announced the release of its Harmony XB4 and XB5 control and signalling pushbutton range. Previously, the colour of the pilot lights on the illuminated pushbutton series was determined solely by the product head. Now, with the universal white LED, Schneider Electric says that it is introducing homogeneity among each colour, with each head featuring the same light intensity –mitigating any possible light spots in the middle of the pilot lights.

The company says that it has also optimised and improved the colours of the heads, allowing for the display of the purest colours possible. This allows for improved distinction of each colour tone (primarily red, orange, and yellow), whether the function is illuminated or not.

Advantages of the new single white LED block include:

- Machine and panel builders will no longer need to pair the heads with the corresponding light blocks, which will facilitate work on bills of materials and avoid potential assembly errors.

- The simplification of the light structure saves time in the selection and installation of the product.

- More efficient stock management for distribution centers, leading to shorter supply times.

- Reduced maintenance as a result of the range simplification.

Schneider Electric explains that previously the colour of the light function was provided by the combined action of the colour diode coupled with a head of the same colour. The LED light is single block. With such a reduction in the number of LED blocks (range sometimes divided by six for a given voltage), the company has reduced the number of references for its LED blocks by 80%, sold alone or in sub-assembly.

EMAIL THIS ARTICLE SAVE THIS ARTICLE

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here