The range of oils, additives and care products produced by industrial equipment supplier BMG contain silicone sealing compounds, which have been developed by Liqui Moly to seal various materials in diverse industries, across the industrial, construction, mining, marine, agricultural and automotive sectors.

Liqui Moly silicone sealing compounds – available in transparent and black – are heat-resistant, single-component sealants that vulcanise under the influence of air humidity and cure quickly to form a permanently elastic mass.

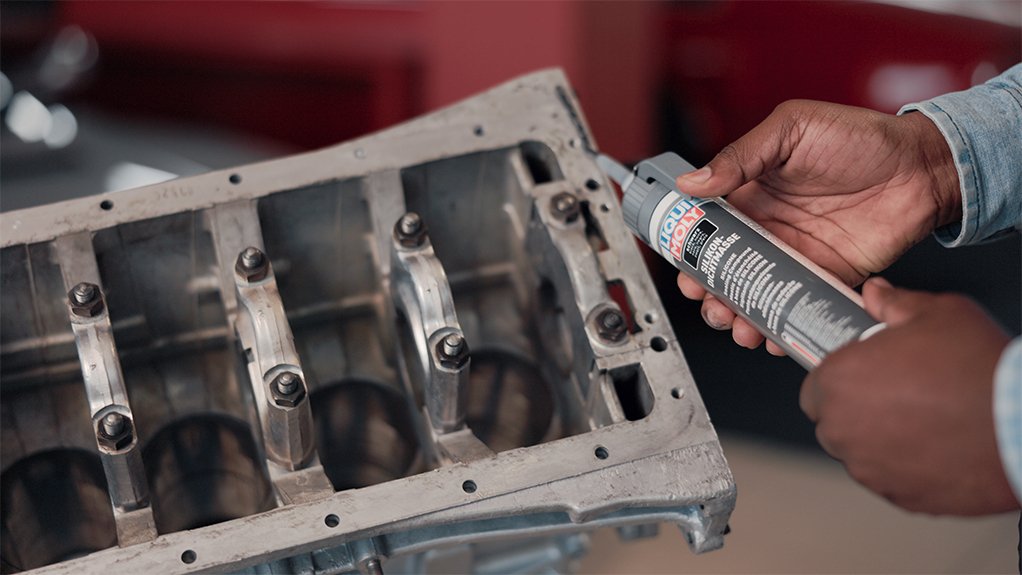

“Our [Liqui Moly] advanced silicone sealing compounds are used to effectively seal materials like metal, plastic, glass, porcelain and painted wood surfaces. This liquid product is conveniently packaged in aerosol form for easy sealing housings on engines, transmissions, differentials, end covers, oil pans, valve covers and water pumps, as well as battery boxes and headlights,” says Agricultural, Automotive and Lubrication business development manager Carlo Beukes.

He adds that containers, engines, transmissions, vehicles and heating, ventilation and air-conditioning systems can also benefit from the use of Liqui Moly’s sealing compound products.

Notable properties of Liqui Moly sealing compounds include good adhesion to vertical surfaces, “excellent” chemical resistance, thermal stability and resistance to stresses and vibrations. These components are free of solvents and formaldehyde and can withstand temperatures from –40 ºC to 250 ºC and, for short periods, up to 300 ºC.

Additional advantages include easy, single-hand application, without mess or waste. Liqui Moly sealing compounds cure in about eight minutes and have an 18-month shelf life in the original re-sealable packaging once opened.

BMG specialists also recommend using Liqui Moly sealant remover to effortlessly dissolve burnt-on and hardened sealing compounds or adhesives from valve covers, cylinder heads, water pumps, oil sumps, flange seals and vehicle, engine, exhaust and mechanical parts. The fast-acting sealant remover offers “substantial savings” in time and effort, making a cleaning task that was previously laborious and costly, totally painless.

Liqui Moly chemicals, which were developed in Germany “to the highest quality standards”, reduce operational and maintenance costs, and enhance environmental protection.

Edited by: Nadine James

Features Deputy Editor

EMAIL THIS ARTICLE SAVE THIS ARTICLE

ARTICLE ENQUIRY

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here