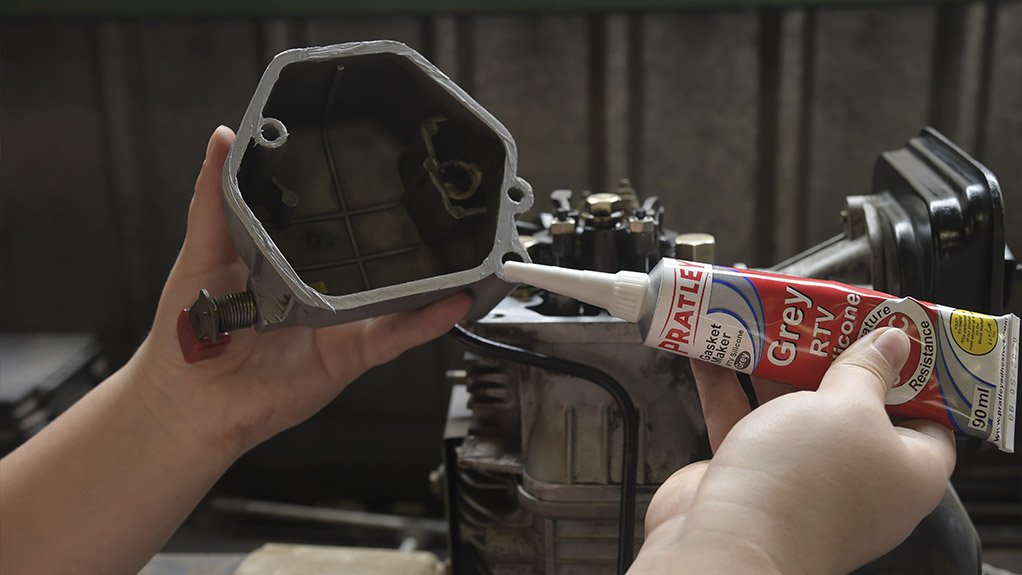

Since launching its RTV Silicone Gasket Maker, industrial products and adhesives manufacturer Pratley says there has been a positive uptake by the automotive component and maintenance sectors.

The gasket maker is an aftermarket product aimed at vehicle mechanics who repair automotive components and equipment.

Pratley national sales and marketing manager Mark Bell tells Engineering News that there has been “significant interest” in the product. Albeit a new product to the Pratley range, “we have been supplying products to the automotive sector for at least 60 years”.

He points out that most do-it-yourself adhesives and sealants can withstand temperatures of just over 100 °C.

However, the RTV Silicone Gasket Maker – a neutral cure silicone-based product – can withstand temperatures from –50 ºC to 300 ºC for short periods of time.

This makes the gasket maker better suited to commercial and industrial applications, as well as mining machinery applications such as winch gearboxes and sealed housings of all descriptions.

“We know that other popular uses include pipe flanges, engine sump covers, gearboxes, water pumps and any other component where a gasket maker is required.”

Uptake of the gasket maker in the retail automotive aftermarket in other African countries has also been notable.

Besides the Pratley RTV Silicone Gasket Maker, another new product is Pratley FrogzEggz, a hand mouldable plastic launched in the second half of 2018. This displays the diversity of Pratley’s products and the industries the company caters to.

The company also plans a hi-tech production machinery upgrade of its factory. This follows its recent commissioning of a high-end electrical testing laboratory, which particularly focuses on the International Electrotechnical Commission 60079 specification for hazardous environments.

Pratley has also invested in quality analysis equipment for its adhesive laboratories at its research and development facility in Krugersdorp, Gauteng.

Another notable adhesive development by Pratley in the last few years is Powda Bond, an almost instant repair system and gap filler. The product consists of two powders and a penetrating adhesive, which is ultra-fast curing and bonds to almost any material.

“Pratley aims to always be at the forefront of adhesives technology and, thereby, stay one step ahead of competitors and this is the basis of its company policy statement,” suggests Bell.

“Our new Pratley RTV Silicone Gasket Maker is an example of a refinement of our product range to cater for specific end-user requirements, as well as to enable the company to tap into a range of niche markets,” highlights Pratley CEO Kim Pratley.

Edited by: Zandile Mavuso

Creamer Media Senior Deputy Editor: Features

EMAIL THIS ARTICLE SAVE THIS ARTICLE

ARTICLE ENQUIRY

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here