JOHANNESBURG (miningweekly.com) – Mining equipment and services provider Sandvik Mining and Rock Technology on Tuesday officially opened its new R15-million production unit in Boksburg.

The opening of the new 1 500 m2 facility, which has ten production bays, coincided with the launch of the 5 t Sandvik LH115L low-profile load haul dumpers (LHDs), which is new to the South African market and targeted for use in narrow reef orebodies, commonly found in the South African chrome and platinum sectors.

The facility employs 15 people, who were trained specifically to assist in the assembly of the LH115L LHDs.

Sandvik’s current South African workforce totals 1 400, with the bulk based at the regional hub in Jet Park, seven main branches and multiple mines and workshops across the country.

Sandvik Group CEO Björn Rosengren on Tuesday said the group viewed South Africa as an “exciting market” for the company. He noted that this was a significant factor in the company deciding to establish its own local manufacturing facility for the complete production of LH115L LHDs and also highlighted Sandvik’s commitment to making a meaningful contribution to the South African economy.

“Southern Africa makes up about 15% of Sandvik Mining and Rock Technology’s mining equipment sales worldwide, with 80% of our low-profile equipment sold into the South African and Zimbabwean markets.”

Rosengren noted that Sandvik had almost 70 years’ history of servicing the South African market and, during this time, it had become well-acquainted with the challenges facing the country’s mining industry and understood the importance of modernising the role that private investment and local manufacturing could play in extending mine life, skills development and employment and the achievement of sustainable, inclusive growth.

He pointed out that Sandvik had identified the opportunity to support the local industry through the local manufacture of Sandvik products and localisation of machines, supporting both employment and local suppliers.

Additionally, Sandvik product area load and haul president Mats Eriksson said Sandvik’s product area load and haul division was bringing its global standards and processes in the form of high-quality manufacturing to this new facility.

“We are creating knowledge transfer to set up the proven processes and systems that we already have in our other manufacturing locations around the world so that we can be in a position to add other Sandvik products to this manufacturing site when needed,” he stated.

Further, Sandvik Jet Park product area load and haul production manager Steve Greisiger commented that once Sandvik decided to invest in the manufacturing facility, it started prototype operations in July and would initially produce LH115L machines. “Facility operations will follow a staged approach, with capacity ramping up based on customer demand,” he said.

Sandvik Mining and Rock Technology Southern Africa sales area VP Simon Andrews highlighted that, in addition to being produced locally, 67% of the machines’ materials had been locally sourced using local suppliers, locally sourced components and local employees.

He said the LH115L machines were cost-efficient and durable and had been developed and optimised for local mining conditions. It is also the first product to be manufactured locally.

Andrews stated that the Sandvik LH115L machine built on the “proven capabilities” of its predecessor, the EJC115L, with the latest safety features.

The new LH115L loader has high availability and is easy to maintain, resulting in significantly better lifetime operational costs. In addition, Sandvik provides the full low-profile portfolio offering of underground drills and bolters to ensure matching sets of equipment.

The LH115L complies with the latest safety requirements and, with its powerful drivetrain, robust frame designed for low-profile operations and simplified electronics, is optimised to provide high levels of availability and unequalled productivity in the harshest African conditions.

Sandvik also revealed that the first four trial units of the machines had already been sold and that it had produced another four, which were ready for sale.

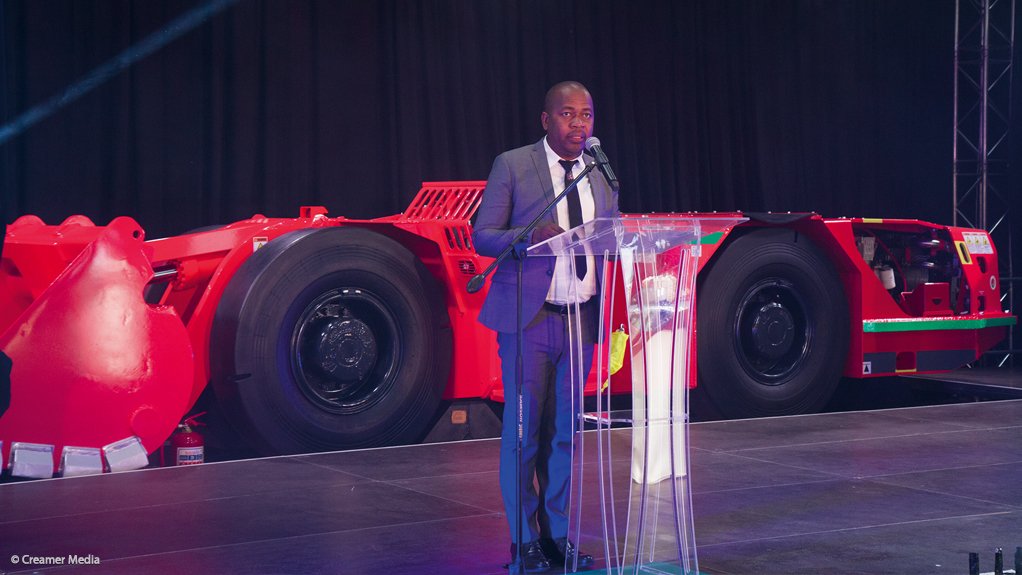

MAYORAL ENDORESMENT

Ekurhuleni mayor Mzwandile Masina also addressed guests at the event and praised Sandvik for its investment in establishing a production facility in the city and for the launch of the LH115L.

“The LH115L marks a significant improvement to the processes of mining in the country and adds to the city’s long and illustrious mining and mining equipment supply history,” he stated.

Masina called on multinational industrial companies to follow Sandvik’s lead by establishing new production and service centres locally, to advance technological innovation, assist in the upskilling of locals and ultimately address the challenge of high unemployment, particularly among the youth.

Edited by: Martin Zhuwakinyu

Creamer Media Senior Deputy Editor

EMAIL THIS ARTICLE SAVE THIS ARTICLE

ARTICLE ENQUIRY

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here