In 2021, South Africa produced about 720 000 t of refined aluminium, becoming the largest aluminium-producing country in Africa, says Aluminium Federation of South Africa (Afsa) CEO Muzi Manzi.

“A large proportion of the primary metal produced is used in the local market as remelt ingots to produce castings and powders, with the rest of the metal destined for exports.”

The primary metal that flows into the local market is considered a ‘lifeline’ for the local aluminium industry, as it contributes towards attaining the goals set out in the South African Aluminium Industry Roadmap (SAAIR).

The SAAIR aims to ensure that, as primary metal flows into the local market, a competitive downstream aluminium sector is created, doubling demand, which will enable South Africa to become a net exporter of semifinished and finished aluminium products, says Manzi.

The Future of Aluminium

Manzi says manufacturing and packaging have become the largest sectors for aluminium demand.

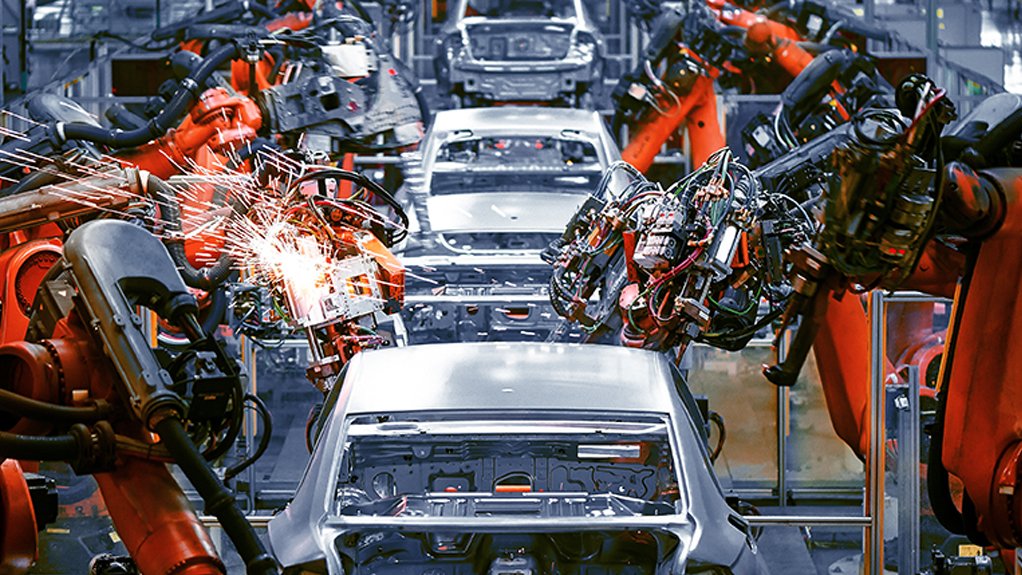

Demand in these sectors is continuously increasing, owing to the demand for increased local supply in South Africa’s automotive sector and the displacement of environmentally harmful packaging materials owing to environmental considerations.

“The industry is anticipating the roll-out of modernised and mechanised cities, which will produce further growth prospects for aluminium use in the construction of infrastructure,” he adds.

Further, aluminium has become the metal of choice in internal combustion engines (ICEs) and electric vehicles because of its lightweight properties, which enables vehicles to be more fuel efficient. It is envisaged that using aluminium in ICE vehicles will accelerate, Manzi comments.

Afsa has noted a significant increase in the use of aluminium in packaging since it has proven to be a more environment-friendly option in comparison to other materials such as polyethylene terephthalate-based containers.

Further, the level of local aluminium recycling ranks amongst the best on a global scale, with a notable increase in the recycling of used beverage cans, adds Manzi.

“In the not-so-distant future, South Africa will see the adoption of aluminium bottles to displace glass bottles, including increased can sizes to about one litre,” Manzi enthuses.

Recycling has increased to such an extent locally that South Africa has become a net exporter of aluminium in scrap metal, a situation the industry is working hard to reverse in favour of local processing of the scrap metal in a drive to green the value chain.

In addition, Afsa has also noted a significant increase in the use of aluminium in the manufacturing of furniture and other household items. The use of aluminium in furniture was born out of the recycling of service aeroplanes and has now transitioned to using newly produced aluminium.

Manzi says this is an indication of the increasing demand in most sectors for aluminium in South Africa.

Green Aluminium

Manzi states that Afsa is at the forefront of ensuring that the drive towards the greening of the aluminium value chain takes precedence at local smelters.

Despite the energy mix, which is predominately fossil fuel-based, there is a significant drive towards a greener future.

Aluminium remains the best material for the construction of window and door frames to attain green building status owing to the material’s ability to regulate internal climatic conditions, he adds.

“Afsa has observed a trend where old, wooden and steel windows in buildings are being replaced with aluminium windows – a trend that Afsa believes will continue to grow.”

Another area of growth for aluminium has been achieved by the country’s enforcement of different renewable-energy projects such as wind or concentrated solar power.

The aluminium industry supplies a large amount of aluminium in the form of ladders, clamps and extrusions to these projects – this is seen as the aluminium industry’s contribution towards the greening of South Africa’s electricity grid, he says.

Further, the expansion of existing secondary smelters, as well the establishment of new facilities producing secondary aluminium ingots for local and export markets, serves as a contribution toward the circular economy and the acceleration of the industry towards net-zero carbon emissions in aluminium production by 2050.

A growing aluminium industry will contribute towards job creation and State revenue in the form of taxes and the upliftment of communities in which the industry operates.

Edited by: Zandile Mavuso

Creamer Media Senior Deputy Editor: Features

EMAIL THIS ARTICLE SAVE THIS ARTICLE

ARTICLE ENQUIRY

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here