Induction bending is a highly specialised pipe bending technique designed to reduce the number of field welds, expedite construction and optimise project schedules. The cost and complexity of long-term maintenance can be improved by reducing the number of welds that require regular inspections. Induction bending is especially beneficial for high-pressure piping, steam piping and industrial piping systems and for complex 3-dimensional bends in pipeline systems.

Steinmüller Africa notes that it holds the only Cojafex PB 850 induction bending machine in Africa and has conducted over 6 300 induction bends on a local and international scale at its local manufacturing facility.

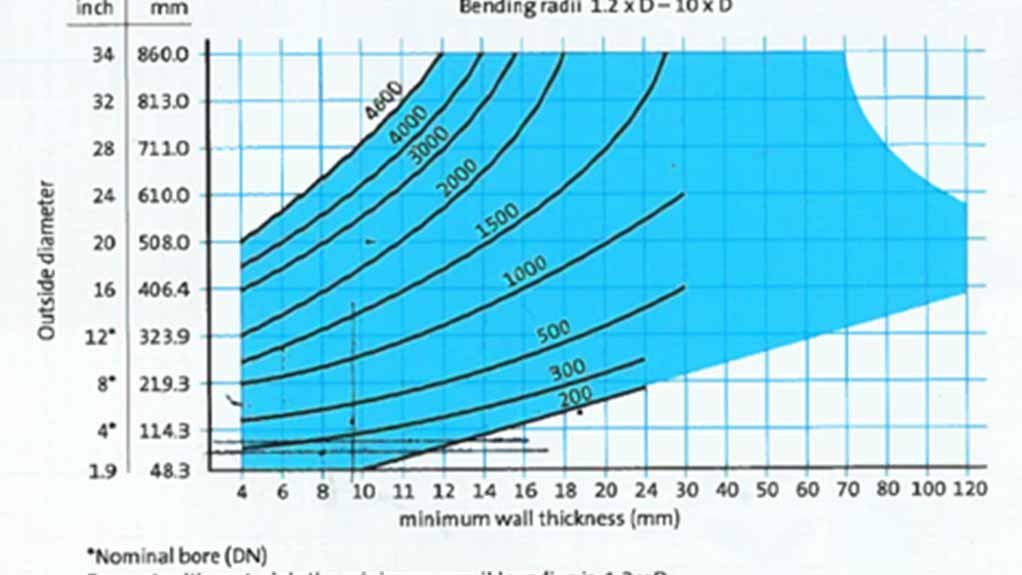

The machine can bend pipes with a minimum outside diameter of 48.3 mm and maximum of 870 mm, and a minimum wall thickness of 4 mm and a maximum of 120 mm. The company can also consider thicker walls, depending on specific technical details.

Steinmüller Africa offers its service to the paper and pulp, power, petrochemical, mining and metallurgical industries. Steinmüller Africa asserts that it has almost 10 000 welding procedure specifications across a range of alloy materials. The company is a specialist service provider across the fields of welding, environmental technology, manufacturing, maintenance, lifetime extension plans and project management.

EMAIL THIS ARTICLE SAVE THIS ARTICLE

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here