Chemicals and process engineering company Lodestone Engineering is set to complete the supply of equipment as part of an upgrade to an existing large wet scrubber for a major platinum producer in Rustenburg by the end of this month.

Valued at about R10-million, the project upgrades an existing 3.6-m- diameter scrubber with a flow rate higher than 80 000 Am3/h.

“The options available for this project were to upgrade the existing scrubber to a high-pressure drop unit and avoid large costs associated with increased fan size, as well as ducting and equipment modifications to handle the higher pressure,” says Lodestone Engineering MD Dirk Schreuder.

Another option was to install wet electrostatic precipitators with significantly higher costs.

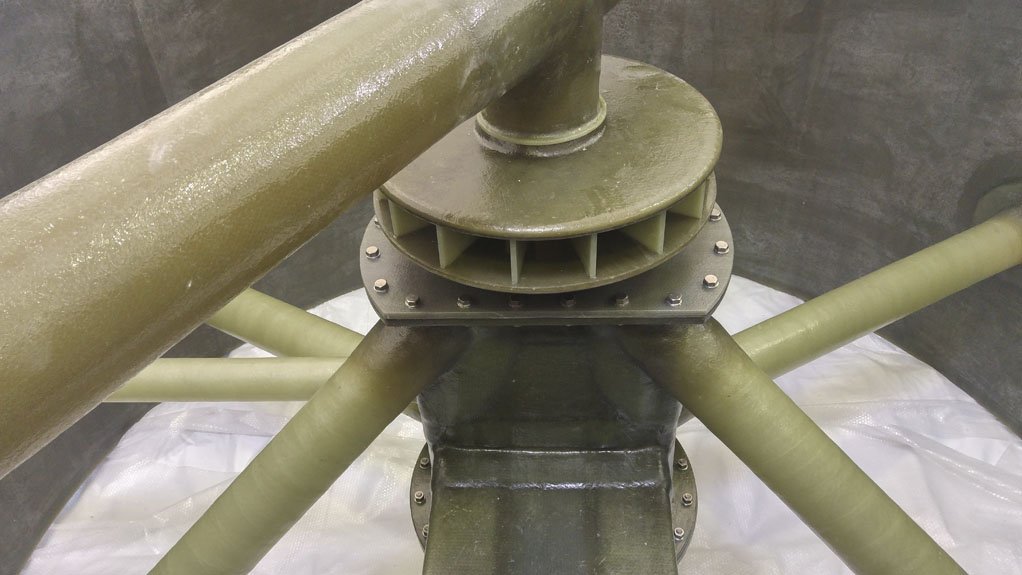

The solution decided upon, however, was to install a rotary scrubber stage within the existing wet scrubber to achieve the required particulate removal efficiencies, and instead of adding the additional energy requirements through larger fans, the energy is added directly into the scrubber vessel, Schreuder explains.

He further notes that rotary scrubbers – within an existing wet scrubber – efficiently remove submicron particulates, and are economical, compared with other technologies such as wet electrostatic precipitators.

Rotary scrubbers are also suitable for high and low variable flow rates, with the “added bonus” of having a low additional pressure-drop requirement.

“This type of technology is very good for retrofit solutions, as, in most instances, only an additional segment needs to be installed in the existing scrubber column.”

There are many wet scrubbers in operation throughout South Africa, with many being between 10 and 30 years old, Schreuder says; however, they were designed for emissions that do not meet the ever- increasing stringent standards applicable today, he adds.

Schreuder mentions that upgrading wet scrubbers generally entails increasing pressure drop, with the associated upgrades to fans, ducting and equipment, which are costly.

He concludes by saying that one needs to look at the different options that are available for each operation and incorporate them according to requirements and client needs.

Edited by: Zandile Mavuso

Creamer Media Senior Deputy Editor: Features

EMAIL THIS ARTICLE SAVE THIS ARTICLE

ARTICLE ENQUIRY

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here