Copper and copper alloys are significant materials in manufacturing with about 26-million tons of copper used globally in the production of electronic appliances, electricity, heating and air-conditioning, plumbing and architecture, explains industry body Copper Development Association Africa (CDAA) nonexecutive chairperson Evert Swanepoel.

“Copper is one of the oldest metals known to man and the smelting of copper dates back thousands of years. It is the best electrical and thermal conductor of all nonprecious metals and has become essential for our lifestyles.”

He notes that, as copper is 100% recyclable, one-third of copper demand is met through recycled copper. He adds that the “huge” demand for copper globally has created a lucrative market for copper scrap.

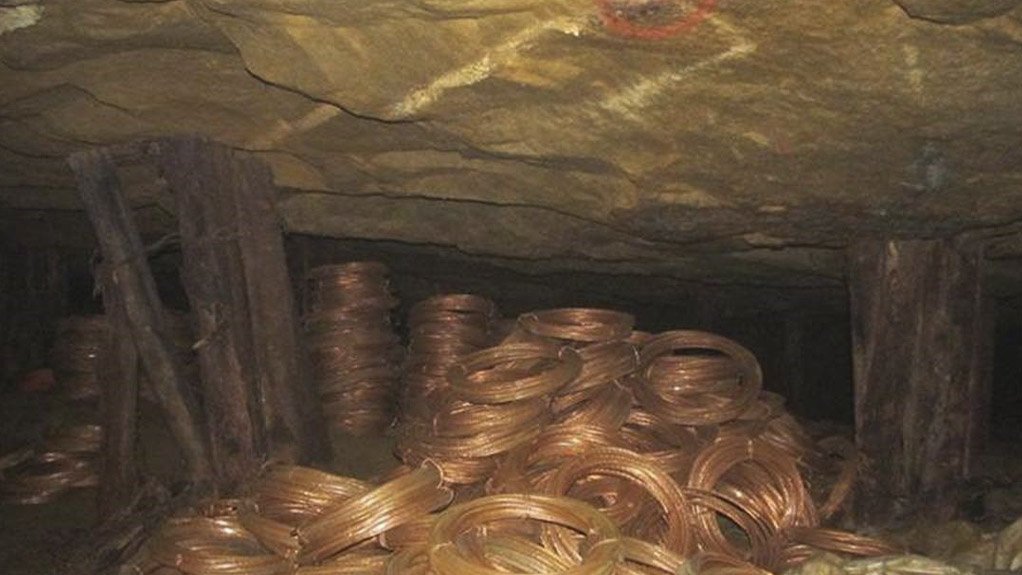

Further, as a result of the global demand, thousands of metres of copper cable are dug up and sold for cash to “unscrupulous merchants”.

Swanepoel notes that these copper cables drive the economy, but their being stolen negatively impacts on State-owned power utility Eskom, State-owned freight logistics group Transnet and telecommunication networks.

As a result of copper theft, the market is seeking alternative materials to replace copper, which is shrinking the copper market.

South Africa can help meet local copper demand by reducing its export of copper scrap and improving downstream development for copper products, he says, highlighting that, as global demand consistently increases, overseas markets offer exorbitant prices for South African scrap copper.

This, in turn, hinders local producers from obtaining quality scrap at reasonable prices, resulting in a reduction in capital expenditure and employment.

Swanepoel notes that government will introduce a tax on the exporting of scrap this month, but cautions that, since most scrap leaves the country illegally, the tax will not materially reduce the export of copper scrap and, therefore, will not address the lack of quality copper scrap for local manufacturers.

It is also CDAA’s opinion that the export of copper scrap fuels the theft of copper cables and, as such, the damage to key infrastructure will continue.

Swanepoel says there are penalties in place for copper theft, and although minor theft is fairly successfully pursued, the bigger organised syndicates are difficult to bring to book, as there are not enough container inspectors available to investigate the number of cases that occur.

He also cites government’s previous attempt to assist local industry by introducing scrap export guidelines in 2013; however, this was ineffective, as a number of export merchants soon circumvented these rules, with huge volumes of scrap still exported illegally to date.

Consequently, if government does not consider restructuring the guidelines, this will result in the local industry’s continued decline.

Demand for Copper

Swanepoel highlights that wind turbines use 3.6 t/MW and photovoltaic energy uses 4.5 t/MW more copper than conventional coal-fired power stations. Fuel-powered vehicles use about 25 kg of copper, with hybrid vehicles and electric vehicles (EVs) using 50 kg and 75 kg respectively.

In addition, the demand for copper is expected to increase significantly, owing to the increased uptake and development of renewable energy and EVs.

“Copper is becoming a vital ingredient in the green revolution and the use of one ton of copper eliminates 600 t of greenhouse gases. Further, the importance of the circular economy is set to increase and recyclable materials will be viewed as prized commodities.”

Swanepoel adds that the demand for copper globally will exceed supply over the next ten years and “nowhere will it be more devastating than in South Africa”.

The only commercial copper mine in South Africa is owned by the Phalaborwa Mining Company in Phalaborwa, in Limpopo. It cannot meet the demand of the copper industry in South Africa, and many large manufacturers rely on scrap or recycled copper.

Government should gain control over the export of copper scrap and help develop new copper mines. Further, government and local industry should strive to resolve the problems at the National Regulator for Compulsory Specifications and the South African Bureau of Standards to improve product standards and ensure that substandard products are not manufactured locally or imported into the country.

In addition, the copper industry should increase training of artisans, particularly in the plumbing and electrical industries.

Swanepoel states that the CDAA is working with the Department of Trade, Industry and Competition on a copper master plan to grow the local industry, create job opportunities and improve exports.

However, without the adequate supply of raw material, this strategy is not feasible. Making the plan feasible would require a stable economy, the availability of raw materials and the improvement of industry standards, he concludes.

Edited by: Nadine James

Features Deputy Editor

EMAIL THIS ARTICLE SAVE THIS ARTICLE

ARTICLE ENQUIRY

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here