With more sophisticated components being used in diesel engines today, maintenance has become more of a challenge for plant operators and this has been exacerbated by the continued lack of available skills.

Diesel engine component remanufacturer, Metric Automotive Engineering says this situation has been made worse with so many different heavy equipment brands available in the country.

“As a result of globalisation, numerous origi- nal-equipment manufacturers (OEMs) have penetrated the equipment market, and this has meant that plant operators need to cater for all the different machines in terms of parts stockholding. It therefore becomes expensive as the majority of these parts are imported stock and plant operators will need to cater for a wider spread of machine brands than previously,” says Metric Automotive Engineering opera- tions director Andrew Yorke.

He tells Engineering News that being able to maintain a parts stockholding commensurate with the plant fleet is vital to ensure optimum uptime of the equipment, but owing to the cost factor this is not always feasible. Where equipment breaks down and parts are not available locally, companies often have to wait for these to be flown in at a significant cost and this also results in extended unplanned downtime of machinery with the associated additional cost of lost production.

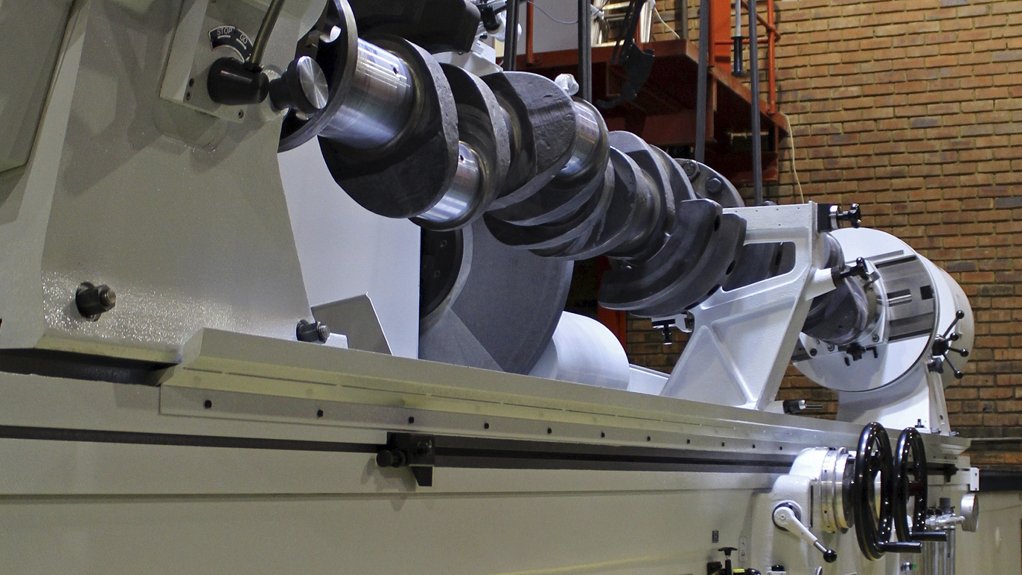

Yorke say this situation has led to an increased demand for Metric Automotive Engineering’s diesel engine component remanufacturing services. It is often more cost effective to remanufacture a component locally than to import the replacement part.

He adds that there is also the advantage that the remanufacture of a diesel engine versus replacing it with a new one is substantially cheaper and the completed engine is put back into service with a new warranty.

“All components are remanufactured to OEM specifications so that when comparing a brand new component with a remanufactured component, they would be within the same speci- fication,” Yorke points out.

He reiterates that all work undertaken by the company is in line with International Organisation for Standardisation standards and customers can reduce costs without compromising on quality.

It is possible to salvage diesel engine components that might previously have been considered as scrap and using the technology available at the company to remanufacture these components.

“That is a huge saving for customers, as engines depreciate and customers have to consider that using remanufactured parts is more cost effective than buying a new component,” Yorke mentions.

Additionally, Metric Automotive Engineering subsidiary and diesel fuel injection service centre, Reef Fuel Injection Services – located in Germiston, Johannesburg – focuses on the maintenance, servicing and repair of fuel pumps and injectors. These components operate at much finer tolerances and, therefore, require frequent servicing and maintenance, he adds.

Yorke notes that, during the life span of an engine, a recalibration of the pump and injectors will be required two to three times before the engine needs to be overhauled.

“Even in tough times, the last thing you want to do is skimp on your maintenance and your servicing because, in the long term, the cost is exponential,” he concludes.

Edited by: Zandile Mavuso

Creamer Media Senior Deputy Editor: Features

EMAIL THIS ARTICLE SAVE THIS ARTICLE

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here