Data-driven mining inherently poses challenges with regard to the planning of mine operations, states mining industry hardware and software supplier Maptek Africa GM Nick Venter.

A fast turnaround is essential for efficient and effective mine planning, as there is a narrow window during which data can be collected, modelled and fed into the next planning cycle, he says.

Venter tells Mining Weekly that data collected throughout the mine life cycle must be processed in such a way that profitable information relevant to decision-making is at hand at all times. When developing solutions for data collection, Maptek has looked to technology that is scal- able, searchable, synchronised and fast, thereby enabling customers to work with a single source of technical data.

Maptek MD Peter Johnson notes that the company has adopted a solutions-focused approach to the collection and analysis of technical mining data. The company understands that to achieve business objectives, challenges must be overcome, processes carried out and goals reached. Johnson believes that Maptek products are more tightly aligned, allowing for its solutions to cross mining processes.

The company focuses on assessing and enabling the best technologies available for hand- ling extremely large geospatial datasets, Johnson says. Maptek works with third-party providers of sensing equipment to drive the automation of geospatial data collection and measurement to integrate this data with the mine planning process.

Maptek’s data-driven safety solutions target applications such as face mapping, geotech- nical analysis, surface movement tracking and reporting on design conformance. The collection and delivery of this information within a relevant timeframe helps to ensure that the safety of operators is not compromised, stresses Venter.

Information is of great value in trying to keep mineworkers safe. Johnson says structural and geotechnical analysis on laser-scanned work- ing surfaces provides up-to-date and detailed information on joint planes, faults and geotech- nical hazards to machine operators. Not only does this lead to improved safety outcomes but also reduces risk of wall collapse that translates into fewer chances of downtime, Venter explains. This confidence in the structural stability and performance of mine walls also enables engineers to plan more efficiently, adds Johnson.

“Maptek survey tools can be applied to underground environments, where measuring surface and structural features in accurate three- dimensions support reliable stope construction. As such, resource recovery is increased without compromising safety,” he asserts.

As part of the company’s innovative range of monitoring products, remote sensing solution Maptek Sentry monitors and reports on movements that have the potential to interrupt mining. Johnson says the product offers significant advantages for the monitoring of low-wall stability and is a cost- effective means of acquiring fast and responsive surface-change data over large areas.

Underground mines are wet, hot and noisy, with limited data connectivity, no light and no global positioning services. There is limited line of sight and machinery operate in tight spaces. However, Johnson states that there are also ultralarge opencut mines, where a single pit could easily be 4 km wide. These mines are dusty and hot with hazardous ground conditions and access to mining areas is restricted.

Johnson states that Maptek’s I-Site laser scanning system, unlike traditional measurement systems, meets the requirements for safe and accurate data collection. The system is IP65-rated to withstand the rugged conditions synonymous with the mining industry, while the remote and flexible mobile set-up helps to ensure the safety of equipment operators.

Meanwhile, more than 8 000 licences for the company’s Vulcan software are used at mines worldwide and, with the release of a updated version, most of these users will upgrade to the new Vulcan 10 software as soon as possible, explains Johnson.

“Vulcan 10 heralds a new era in user experience with the introduction of the Maptek Workbench, an integrated platform for the development and delivery of products and services. The Workbench defines our future as a global mining technology leader and establishes a new environment for ongoing innovation in product development,” comments Johnson.

While developing the pro- duct, Maptek had to resolve compatibility issues between more mature products and new pro- ducts to ensure an auditable data flow across mining processes.

The key to software design is how it relates to the user, Johnson says, adding that this is especially true in critical value markets such as mining. Simply developing new applications is not enough, he emphasises, as the developments must improve the operational workflow and respond to prac- tical concerns of the user base and the relevant business environment.

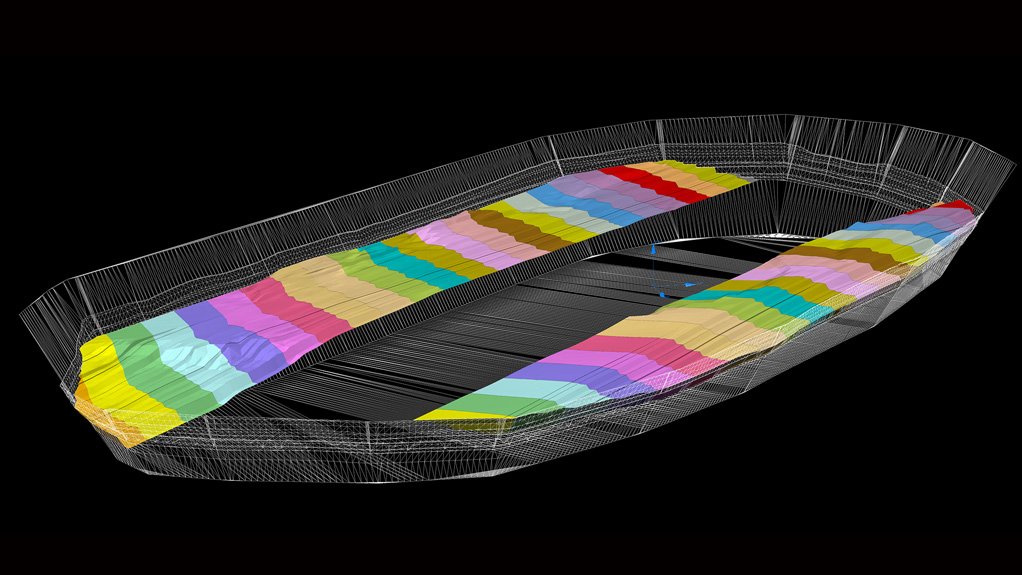

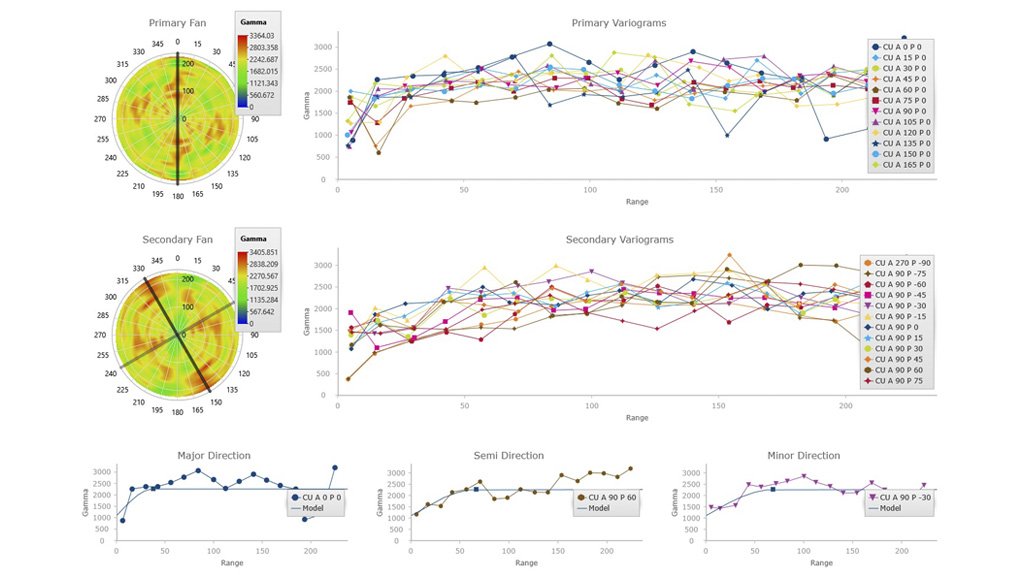

Maptek’s new approach to vario- graphy is a good example of the company’s emphasis on ease of use, says Johnson. “Fourteen menu items have been streamlined into a sophisticated tool that provides new methods for handling structural- and grade-based anisotropy [the property of being direc- tionally dependent]. Resource geologists have access to alternative methods to evaluate data, displaying multiple models concurrently for real-time, side-by-side comparisons.”

Edited by: Tracy Hancock

Creamer Media Contributing Editor

EMAIL THIS ARTICLE SAVE THIS ARTICLE

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here