With its battery anti-theft solution successfully protecting more than 15 000 lead acid batteries in South Africa, battery and related-components supplier Aztec is seeing an increase in demand for premium-quality batteries with a longer operating life.

“In the past, many operators decided to install low-quality batteries instead of premium batteries, as the full operational life of the batteries was seldom achieved before they were stolen. However, with Aztec’s anti-theft solution – introduced in 2015 – it now makes sense from a financial and technical perspective to reinstall premium-quality batteries,” says Aztec electrical engineer Dean Marcus.

Subsequently, there has been an increase in sales of thin plate pure lead and lead carbon batteries for applications such as cellular base towers and data centres. Aztec has also noted a rise in demand for premium lithium batteries in a variety of forms, including rack-mounted modules and wall- and tower-mounted smart lithium power solutions that comprise batteries and integrated rectifiers.

“Battery demand is also being driven by the increased focus on cleaner energy generation. Multiple battery chemistries, including lead acid and lithium, are, thus, set on a strong growth path, as they are in a multitude of different applications from cellular base stations to mission-critical uninterrupted power supplies (UPSs).”

Lithium versus Lead Acid

While lithium batteries are certainly gaining popularity globally, Marcus highlights that lead acid batteries remain strong in the market and, with continual technical advancement, they are still ideally suited to many applications.

“There is no one battery which is perfect for all applications. Batteries form a critical part of many standby power systems and should, therefore, be specified and supplied by battery specialists who can advise customers about the best option . . .”

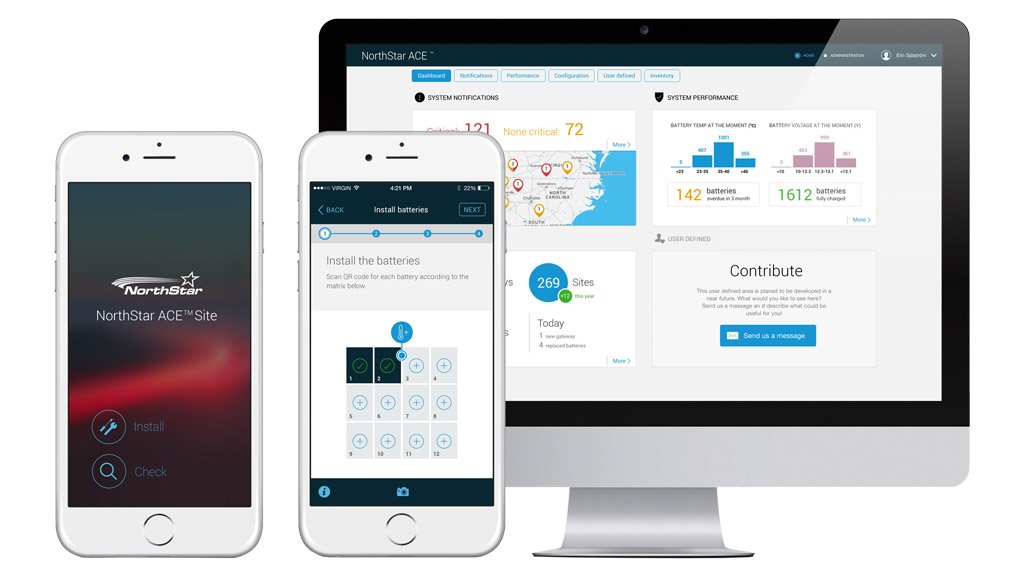

Marcus highlights that lead acid batteries are still advancing, with battery monitoring systems playing a central role in their improvement. He notes that US-based NorthStar Battery Company is leading the way in this regard with its NorthStar Advanced Connected Energy (ACE) solution. This fully integrated battery monitoring solution combines Bluetooth communication with an Internet of Things concept, with a Bluetooth-enabled monitoring device located inside the actual battery, negating the need for any external sensors.

“NorthStar ACE allows for important battery information, such as battery voltage and battery temperature, to be retrieved wirelessly in real time, locally through a smartphone application and remotely through a cloud service. The system improves efficiency at every stage of the process from battery warehousing, installation and operation to replacement.”

Marcus stresses that real-time battery monitoring is important, as battery parameters – such as voltage, temperature and life expectancy – need to be tracked and managed to ensure the optimal battery performance. This is most commonly achieved using external battery sensors integrated with a central controller, which is typically connected to a network or to an Internet-based cloud platform for remote monitoring.

The battery monitoring system is then typically set up to alert the user when certain parameters exceed their set values.

“Battery monitoring is recommended for a multitude of applications and is essential in critical applications, such as railway signalling and data centres. Battery monitoring is an essential tool, as it avoids costly downtime, optimises battery life and reduces replacement costs.”

NorthStar ACE was launched in South Africa this year and Aztec has seen a positive local market response to its advanced capabilities. Aztec also supplies the Powershield 8 battery monitoring system, from New Zealand-headquartered manufacturer Powershield, which is ideal for batteries that are either already installed or do not contain ACE.

In cases where lithium batteries may be the best option, Marcus further notes that there are several different lithium battery chemistries that can be used, highlighting the need for suppliers to understand and communicate the advantages and disadvantages of each to customers.

The three most common lithium chemistries in use globally are lithium iron phosphate (LiFePO4), lithium nickel cobalt aluminium oxide (NCA) and lithium nickel manganese cobalt oxide (NMC).

LiFePO4 cells are available at a relatively low cost, but are not ideally suited to telecoms, UPS and other standby power applications, owing to their lower nominal voltage and subsequent lower specific energy, their higher self-discharge rate and relatively shorter life span. LiFePO4 batteries are, however, safer to handle, which is important for less experienced and competent battery assemblers and manufacturers.

“In contrast, NCA and NMC cells are ideal for telecoms, UPS and other standby power applications, as well as electric vehicle applications, owing, in part, to their high energy and power densities and long life. These two chemistries are more expensive than LiFePO4; however, the advantages they offer far outweigh this disadvantage.”

Marcus highlights that, the battery management system (BMS) in any lithium battery is a crucial component, as it controls the voltage, temperature and other important parameters of the lithium cells.

“The price of a lithium battery is closely related to the type and quality of its cells, and the quality and functionality of its BMS. Many low-cost lithium batteries fail, owing to poor quality-management systems and we are, thus, happy to see that the South African market is starting to realise that there are several important factors, other than the price, which should be considered when selecting batteries,” Marcus concludes.

Edited by: Zandile Mavuso

Creamer Media Senior Deputy Editor: Features

EMAIL THIS ARTICLE SAVE THIS ARTICLE

ARTICLE ENQUIRY

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here