Attention must be paid to the quality and place- ment of hoses in the installation and setup of hydraulic systems as using misapplied or ill-maintained hoses in any hydraulic system is inherently dangerous, says Bearing Man Group (BMG) national product manager Joanne Tarr.

“Working pressure of the hose must be greater than the maximum operating pressure of the system. Fluid tempera- ture, too, should never exceed the maximum working tem- perature of the hydraulic hose. During the setup of a hydraulic system, heat sources within the system must be considered, as this can also lead to the temperature of the hoses exceeding the maximum working tem- perature,” she points out.

Owing to this, BMG emphasises hydraulic hose assemblies should be inspected and pres- sure-tested for leakage and malfunction. If hose systems fail prematurely, this may be caused by installations that are not geometrically compliant with hose specifications or by applications of the system that exceed hose specifications.

Fluid compatibility is another factor to be considered, as chemical degradation can occur if the hose is not adequately resistant to the chemicals used, notes Tar.

“BMG has released a com- prehensive catalogue, which includes a fluid compatibility and resistance chart and technical information on the BMG range of hoses, fittings and adaptors. The catalogue also features a consumer guide to aid in the selection of the correct hose for any application.”

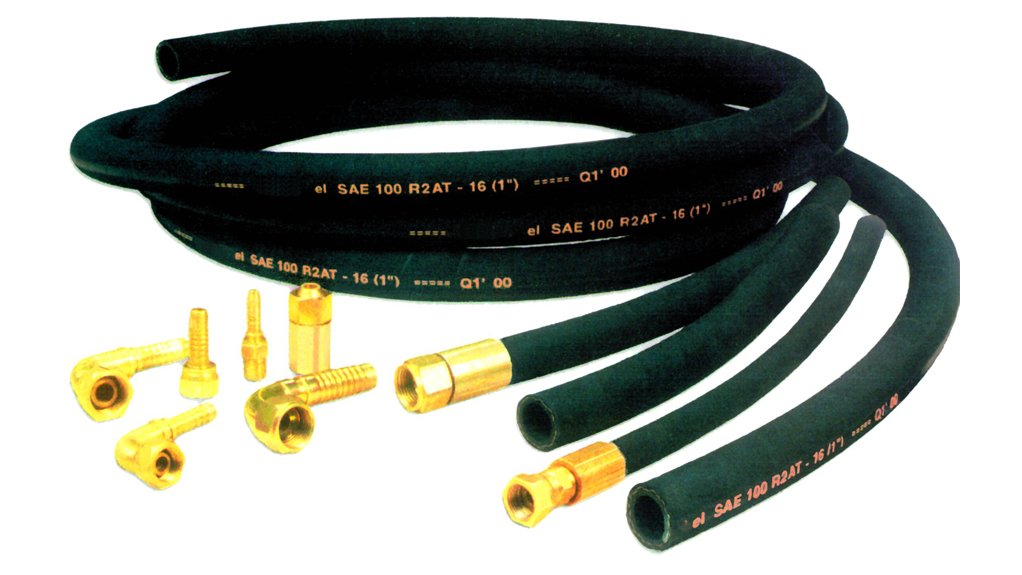

Meanwhile, BMG’s product range, which includes valves, accumulators, cylinders, heat exchangers, hydraulic motors, hydraulic pumps and reservoir accessories, recently expanded with the addition of Eaton Winner braided hydraulic hoses and fittings. The hoses and fittings are designed to match perfectly and provide a safe and reliable transfer of petroleum and water-based hydraulic fluids even in the most demanding applications.

The EN853 1SN (EC210) hydraulic hose boasts a synthetic rubber tube and cover, wire braid reinforcements and a white ink transfer layline. The hose has a bend radius of up to 100 mm, operating temperatures of the hose range from –40 °C to 100 ˚C and the hose can endure pressure of up to 225 bar. The EN 853 1SN (EC210) hydraulic hose is even more impressive with a bend radius of up to 630 mm and a maximum working pressure of 400 bar.

BMG’s fluid technology services comprise project engineering and consulting, cylinder design and manufacture, repair and testing, and even on-site container testing.

Edited by: Zandile Mavuso

Creamer Media Senior Deputy Editor: Features

EMAIL THIS ARTICLE SAVE THIS ARTICLE

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here