Mobile hydraulic solutions provider Stiebel-Getriebebau continues to develop new pump drives to tackle the continuously growing challenges in mobile hydraulics and cope with the harsh operating conditions to which equipment is subjected in the mining environment.

Stiebel drive technology North American VP Mark Johns notes that the company continues to progress the development of new high-technology pump drives that significantly exceed the standard for mobile hydraulic applications.

Visitors to this year’s MINExpo International, taking place at the Las Vegas Convention Centre, in Nevada, in the US, will be able to witness this at Stiebel-Getriebebau’s stand in South Hall. The company aims to expand into the North American market and will exhibit at MINExpo for the first time.

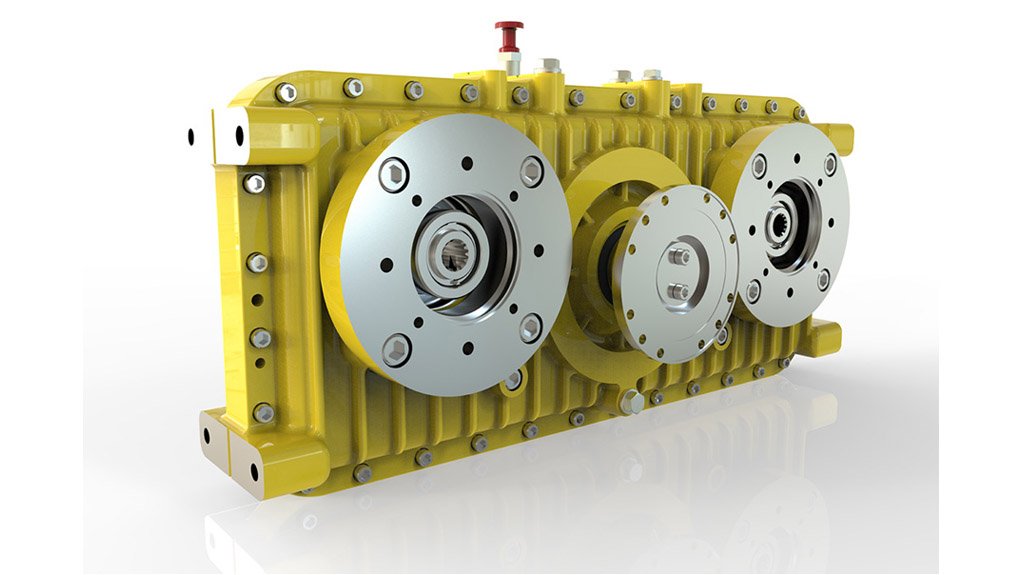

Stiebel says its pump drives combine an improved energy balance, greater flexibility for the most varied applications and impressive performance. For midsized mining excavators and larger (from about 300 t), the Stiebel Type 4462 pump drive provides the driving force. The drive is connected to the 800 kW engine through a Society of Automotive Engineers (SAE) bell housing adapter, which is provided with the drive.

The integrated oil pump and oil distribution system used by Stiebel ensure the most efficient lubrication and cooling of the pump drive. Therefore, sloping positions – of up to 30° in all directions – are possible during operation.

A maximum of six pumps can be fitted on both sides of the drive, actuating all hydraulic functions.

Further, Stiebel’s product offering also includes the Type 4382 single-stage pump drive from its P2000 range. The 530 kW drive provides a solution suitable for a range of mobile hydraulic applications. The robust, torsionally stiff drive employs a proven modular system that offers a comprehensive range of attachments.

The unit is connected using an SAE bell housing or cardan flange. Three pump connections at the takeoff, with a freely selectable SAE connector, are available.

Also on offer is Stiebel’s Type 4652 pump drive with a high degree of adaptability that provides an ideal drive solution, particularly for mobile tracked drilling rigs. This is owing to its particularly compact design, which allows for easy underfloor installation. The geometric offset of the drive/takeoff, the large oil volume and solid ribbing of the casing, result in an “outstanding” energy balance for the pump drive. This means that an additional oil cooler is not usually necessary, Stiebel notes.

The company’s new designs will be displayed on a Caterpillar blast hole drill and another new drive on a Joy blast hole drill.

Johns states that the company is a “widely respected” partner for gearbox solutions in conveyor technology and mobile hydraulics and that, “as a specialist for customised gearbox designs, Stiebel offers individual answers to complex challenges in numerous businesses”.

Edited by: Tracy Hancock

Creamer Media Contributing Editor

EMAIL THIS ARTICLE SAVE THIS ARTICLE

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here