Caterpillar is expanding its service replacement engine program for owners of equipment powered by its engines, giving new alternatives to a major engine overhaul.

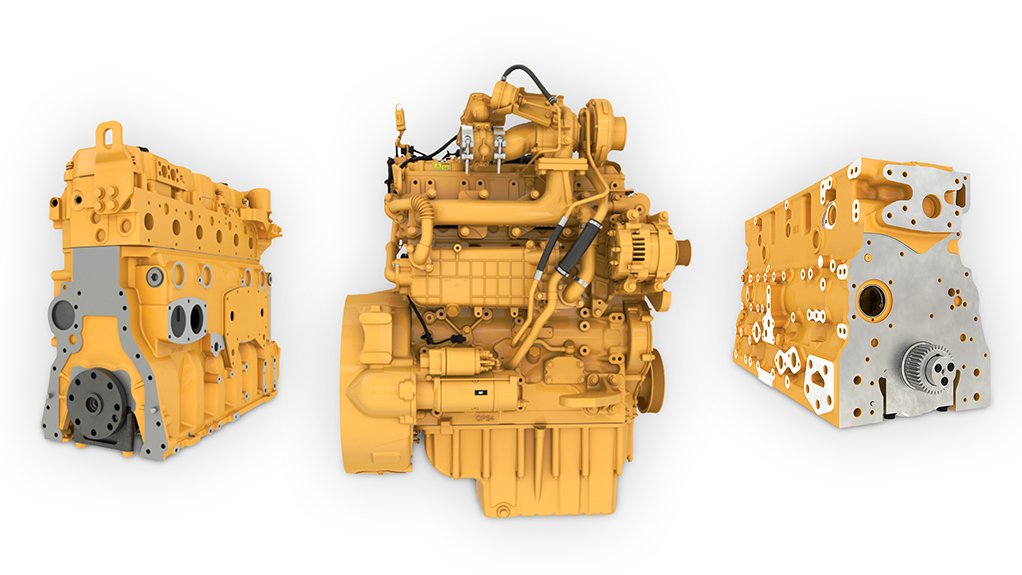

The program consists of four options, including new replacement engines, Cat Reman engines, short block engine replacements and heavy-duty long blocks.

The company offers a range of replacement engines for equipment using engines up to a Cat C7.1 or 320 hp. The range provides solutions for a variety of heavy-duty applications, such as chippers, grinders, pumps and compressors.

The company asserts that the use of new replacement or Cat Reman engine solutions is faster and easier than a complete rebuild and delivers enhanced uptime and productivity. In addition, the program helps equipment owners achieve sustainability goals by using remanufactured components.

“The industrial power industry has an increased emphasis on the refurbishment of machines, and this program provides a great alternative to extend the life without buying brand-new," said global aftermarket sales manager Ron Schultz.

With new replacement engines – from industrial power to generator sets, and construction machines to paving equipment – customers are offered the benefit of new engines built to factory specifications that meet emissions standards and deliver same-as-original performance. This approach is also said to offer reduced repair and overhaul costs, extended warranty protection and a quick turnaround time.

Cat explains that its Reman engines are remanufactured to their original performance specifications through state-of-the-art salvage techniques, adhering to strict reuse guidelines, using advanced manufacturing systems, and following robust quality control. The newly remanufactured Cat engine then re-enters the supply chain, with its lifecycle restarted, ready to be installed.

EMAIL THIS ARTICLE SAVE THIS ARTICLE

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here