Mines are increasingly required to implement programmes showing good practice in local procurement. International standards – as well as local policy and regulation – provide requirements and guidelines, but what really works in the field? This series explores five local procurement topics, highlighting good practice principles, providing case studies from mines and recommending practical initiatives mines can take to improve how mines apply local procurement programmes. In this fifth article, SRK Consulting’s Lisl Pullinger and Andrew van Zyl, as well as Mining Shared Value’s Jeff Geipel, discuss how partnerships are vital in supporting the growth of local enterprises

While mines are often the most well-resourced organisations in an area, they will struggle to single-handedly create a positive and lasting impact on the local economic landscape. Indeed, it is unlikely that their local procurement efforts will succeed at all without the right partners.

It is true that the procurement power of a mining operation will often place it at the centre of the local economy. A mine demands a steady supply of goods and services, many of which can be procured locally – to the benefit of nearby businesses and communities. To actively enhance the sharing of value among local stakeholders, however, a carefully managed collaboration of partners is required.

Partnership, it should be noted, will not in itself produce a positive result. Rather, a systematic approach to supplier development will require that a range of inputs be made, and partners need to be found that can contribute to these different aspects. The failure of many of these programmes is frequently not attributable to insufficient money being invested, for example. Failure is often the result of participants in a mine’s supplier development programme not being connected to the correct organisations or resources.

This ‘resource linking’ is where partnerships make all the difference. Most successful supplier development programmes include linkages to a multitude of support types and potential resources – from finance and mentoring to business and technical training – to which suppliers can be directed. This might require a level of hand-holding from the mine’s side, to ensure that the supplier and resource provider are on the same page, as it were. In essence, though, the mine should be able to rely on another party to take responsibility for each aspect of the supplier development process over time.

Globally, an important role in business support is played by chambers of commerce – which exist almost everywhere in some form at a central, regional or local level. For mining companies, institutions like local business chambers can be valuable partners. Instead of trying to establish their own in-house capacity, mines can often play a more constructive role by strengthening these kinds of existing organisations. This may mean that a mine works closely with a local chamber to enhance its capacity – perhaps in a ‘train the trainer’ role.

It is important to note that, in attempting to cover all the bases in supplier development on its own, a mine can inadvertently create a source of vulnerability. If the roles and duties in these developmental efforts are not shared, there will never be sustainability. Not only could initiatives collapse if a mine’s ownership or priorities change, but it will be difficult to develop the required buy-in and shared responsibility to carry forward economic diversification – especially beyond mine closure.

One of the underappreciated roles that the mine plays as a customer to emerging businesses is to set the bar for quality and performance. This gives suppliers an opportunity to understand and strive for what the mainstream economy demands of service providers. This benchmark provides a crucial target for others in the enterprise support system to rally around, adding their contribution to the supplier’s evolution.

However, it is worth pointing out that this role need not place the mine in the position of controlling the drive for local economic development through its supplier development programme. In fact, the mine should try to avoid assuming such a role. There are other players – including government, business and community bodies – that really need to be at the forefront of these broader efforts if they are to be sustainable.

This sharing of responsibility is vital to embed the understanding that the mine is but one partner in a system that must function collaboratively to achieve success. In South Africa, where local government does not always have the resources and skills to provide support, this message is doubly important. In many countries, government is a central, if not leading, partner in local economic development efforts.

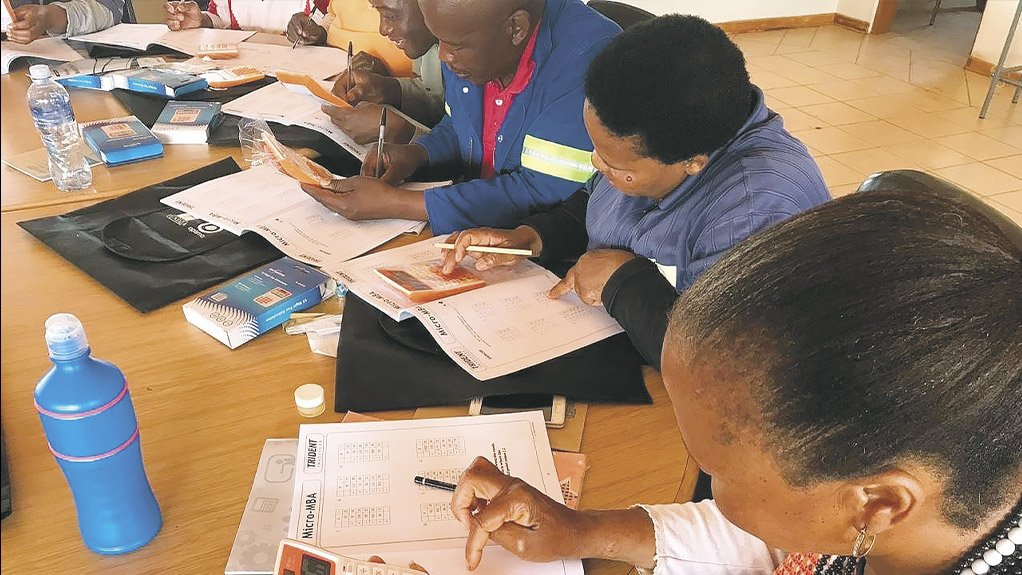

Nongovernmental organisations (NGOs) also play a significant role, often in fields of education such as business and skills training. Some NGOs even offer funding, augmenting the financial contribution of banks and development agencies. A partnership-driven approach is built on this varied collection of inputs, which a mine can help to coordinate without necessarily becoming the dominant player.

Among the key contributions that mines often seek for their supplier development is effective skills transfer – and here partnerships with larger suppliers are useful. By drawing in these suppliers as partners, for instance, mines can further spread the task of developing skills in emerging suppliers. This is already a well-practised option in some countries, where mines include detailed skills transfer requirements into their tenders. In this way, the mines effectively fund those efforts but hand them on to those better equipped to provide them.

A ‘resource hub’ is in many ways an optimal solution to arrange and manage this collaboration. Such a hub comprises not only the partners themselves but also a carefully negotiated system of how mine suppliers can be linked to each partner and supported. Ideally, those taking the lead in such a ‘local ecosystem’ will be organisations firmly embedded in the community, rather than fly-in-fly-out supporters. This will help to keep its efforts grounded in local priorities and ensure that the public face of the initiative is credible and committed.

When conducted strategically – in line with a long-term developmental goal – a mine’s procurement process remains an important vehicle for strengthening and diversifying the local economy. For this to be sustainable, though, mines need to position their supplier development work within a collaborative effort that will ideally continue in other ways long after mining operations have ceased.

Pullinger and Van Zyl are SRK Consulting principal consultant: sustainability and director and principal consultant respectively, while Geipel is MD, Mining Shared Value, Engineers without Borders Canada – lfair@srk.co.za.

Edited by: Martin Zhuwakinyu

Creamer Media Senior Deputy Editor

EMAIL THIS ARTICLE SAVE THIS ARTICLE

ARTICLE ENQUIRY

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here