In the past, individual or single compressor systems were used for most medium and low temperature applications. However, with continuous refrigeration technology development, multiple or parallel refrigeration systems were introduced to the industry.

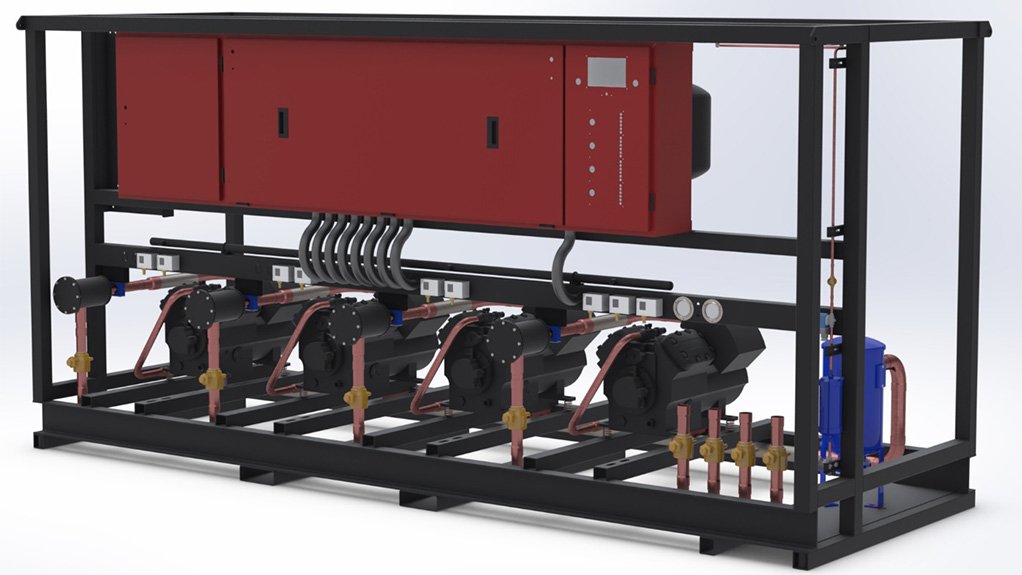

Refrigeration and air-conditioning components and systems provider Metraclark notes that parallel compressor systems are central refrigeration units that make use of three to six parallel commonly piped compressors, single common oil separator, an electrical control panel, and a liquid receiver tank mounted on a remote base frame.

The multiple parallel compressor rack system (multiplex) may be designed for either indoor or outdoor use. The overall selection and design of the multiplex is based on the requirements and limitations of each individual commercial refrigeration specifications.

The most important determining factor for the multiplex specification is the proper selection of the system components for the particular application, the company says.

Applications in the commercial refrigeration industry are mainly focussed on the cold chain used to refrigerate perishable consumables, produce, and products that are required to be stored at different temperature ranges, including for supermarkets, abattoirs, the agriculture sector, cold storage facilities, and freezer warehouses.

Further, Metraclark’s engineering department investigated the base design of the previous Tsunami multiple parallel semi-hermetic compressor rack range that assisted the creation of the design philosophy for the new Metraclark multiplex range.

The design philosophy was set to create a standardised modular design, that maintains simplicity, reduces manufacturing time and manufacturing complexity, increases ease of installation and maintenance, and increases overall efficiency of the refrigeration system.

Metraclark explains that the design philosophy of the new multiplex frame was set to create a complete in-board design of all components fitted to a multiple parallel compressor rack. By creating an in-boards design it becomes possible to build a single frame for both indoor and outdoor application with the addition of cladding.

To begin the process of designing a new multiplex frame, an investigation into thermodynamic first order principle design sizing and selection of all of the components was performed to ensure proper sizing of refrigeration line components (individual and common check valves, individual and common discharge lines, oil separator, and individual and common suction lines) used in manufacturing a parallel compressor rack for a Freon commercial refrigeration system.

This directly ties into the design process of a homogenised multiplex design to reduce manufacturing time and costs.

The overall design of the multiplex frame is directed by the layout between each individual compressor and its connection in parallel, therefore the individual discharge and suction lines are the pivot points to create a modular homogenised design.

T

he company states that the frame has been moulded around the Copeland semi-hermetic compressors and a fixed conceptual three-dimensional (3D) volume. To be able to accommodate all Copeland D3, 4M, and 6M compressors the 3D volume needs to be based on the largest Copeland semihermetic compressor – the 6MU-40X.

The design project aimed to develop a computer-based 3D model of all iterations of the new multiplex on offer at Metraclark, including two-dimensional manufacturing and assembly drawings of the entire mechanical and electrical multiplex design. The development of the design model required thermodynamic first order calculations to determine the correct size selection of individual discharge and suction line components for the 6MU-40X first, and then the rest of the semi-hermetic compressor range allocated to multiple compressor applications.

The individual discharge components include: a vibration eliminator and a non-return check valve. The individual suction line components include: an isolating ball valve, a replaceable filter drier and a vibration eliminator. The isolating ball valve facilitates individual compressor shutoff for maintenance purposes, and the non-return check valve protects the head of the compressor during nonrunning times.

Meanwhile, the centralised main profile shapes the overall frame configuration, and with small alteration it can facilitate both possibilities of standardised and bespoke multiplex designs, resulting in the range of three to six Copeland semi-hermetic compressors in single and dual suction circuit applications.

Further, the new multiplex incorporates a high oil return efficiency helical oil separator coupled with a low-pressure oil management system. The low-pressure oil management system makes use of full column gravitational flow from reservoir, through the common five out eight-inch oil return header, to each individual compressor’s oil level management system.

The design of the electrical enclosure and electrical switchgear layout flowed from the modular compressor and frame design. The new electrical enclosure now has a full left to right switchgear access philosophy, which gives the possibility for the switchgear to be divided into modular individual compressor compartments.

Moreover, an additional improvement to the electrical wiring schematic was to designate a specific letter and number combination to the control wires of each compressor and the main control circuit.

The final aspect of the structural frame design required first order stress and strain calculation verification together with finite element analysis validation.

This, Metraclark concludes, is to ensure that the stresses exerted on to the multiplex frame during manufacturing, transport, installation, and final standard steady state operation do not cause any mechanical or electrical failure.

Edited by: Zandile Mavuso

Creamer Media Senior Deputy Editor: Features

EMAIL THIS ARTICLE SAVE THIS ARTICLE

ARTICLE ENQUIRY

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here