Oxygen is critical to a variety of industries and is used in a range of applications, such as improving the control of heating patterns, increasing furnace efficiencies by lowering fuel consumption and for reducing particulate and nitrogen oxide emissions. Oxygen can also be used with fuel gases to enhance processes such as gas welding, gas cutting, oxygen scarfing, flame cleaning, flame hardening and flame straightening. It is also a raw material in many oxidation processes and is used to regenerate catalysts. Oxygen is essential for a vast number of industries including wastewater treatment, food and beverage, pulp and paper, steel, medical, pharmaceutical, bioenergy, metallurgical, glass and aquaculture.

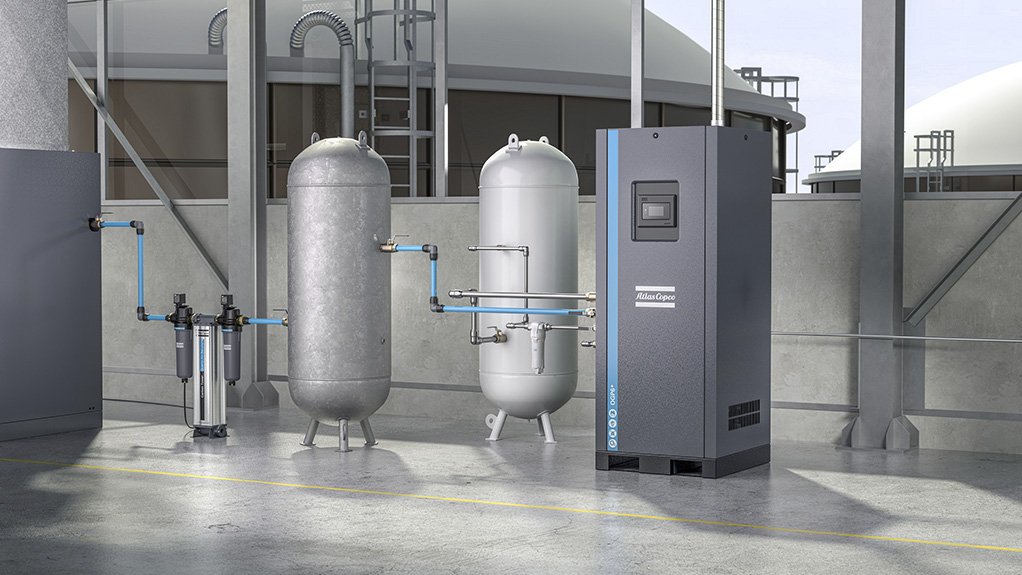

Atlas Copco has recently unveiled its latest range of OGP+ Oxygen Generators that produce oxygen on-site, offering a cost-effective, safe, space-saving, and convenient solution that is also environment-friendly. The company asserts that its new OGP+ 3-30 Pressure Swing Adsorption (PSA) machines deliver best-in-class oxygen generation performance and efficiency. The generators are designed to ensure continuous reliable on-site oxygen generation at a significantly lower total cost per unit of oxygen, optimised uptime due to continuous oxygen supply and the delivery of guaranteed gas purity. In addition, the machines enable users to choose the correct oxygen purity level for a specific application.

“With our OGP+ Oxygen Generators, professional oxygen users can become oxygen producers,” states Atlas Copco Compressor Technique business line manager Zandra van der Westhuizen. “To switch from sourcing the gas from a vendor to producing oxygen on-site is easy. All that is required is a compressed air system plus a gas generator and the plug-and-play machine is ready to produce oxygen on-site.”

Additional benefits of Atlas Copco OGP+ generators include:

- 30% more efficient at full load compared to a traditional generator.

- Variable cycle saver technology, enables up to 70% additional energy savings when oxygen demand is low.

- A dependable and continuous supply source, reduces potential stoppages as a result of stock shortages.

- Users can control the amount of oxygen needed at the correct purity required for the particular application.

Van der Westhuizen points out that the purity of purchased oxygen is usually over-specified for most application requirements. “An on-site generator not only achieves this high purity more cost-efficiently, but it also offers additional savings. Because generating oxygen of the highest purity uses more energy, the ability of on-site generators to set the correct purity for a particular application will significantly reduce the user’s operational costs.”

Another advantage offered by on-site oxygen production is that there is no need for a facility to store oxygen cylinders or to install a large liquid oxygen tank. The OGP+ generator has a small footprint requiring only a small space in a production facility, owing to the use of aluminium extrusions and zeolite molecular sieve material that separates the oxygen from the incoming air.

In addition, using an on-site generator reduces the need for long-term contracts, diminishes problems related to logistics and safety concerns that accompany the ordering and handling of third-party oxygen cylinders, and eliminates oxygen transport and delivery reducing the user’s carbon footprint.

The Atlas Copco OGP+ generator is supplied standard with an oxygen sensor, a digital flow meter, a pressure regulator and an automatic startup function. The machine features a new advanced controller with a large HD colour touchscreen that enables easy, user-friendly navigation through options such as oxygen purity selection and purity alerts. The automated 24/7 feed air and oxygen monitoring and interception function helps to safeguard the quality of the OGP+ generator’s performance and output.

EMAIL THIS ARTICLE SAVE THIS ARTICLE

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here