Sustainability has propelled the creation of new technologies, with the economical use of energy resources becoming an important objective within metalworking companies, says fluid technology solutions specialist technotrans business development manager Hary Kosciesza.

Consequently, technotrans Sassenberg will be introducing its new resource-preserving spray lubrication systems at the Blechexpo 2024.

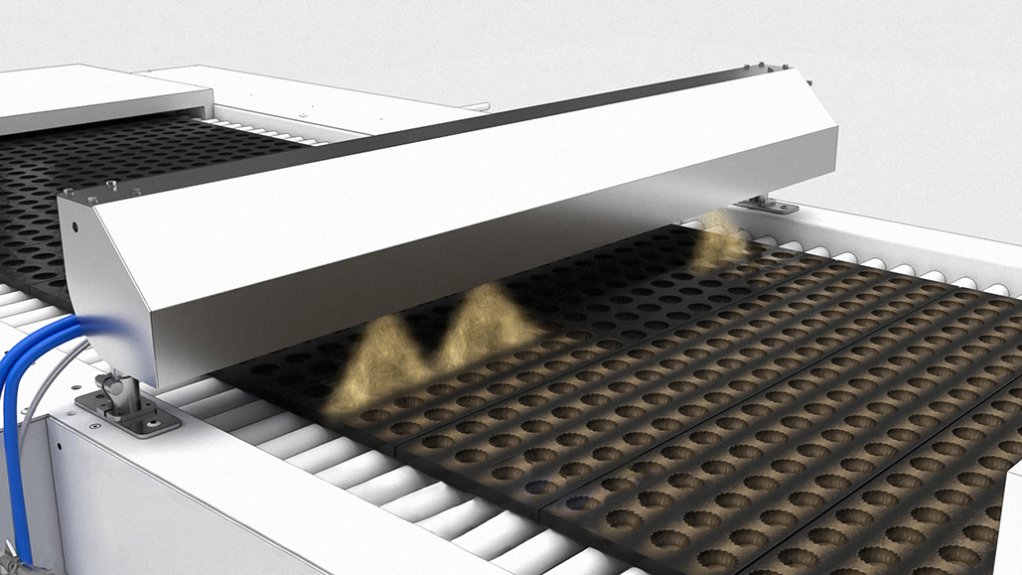

Kosciesza explains that technotrans’ spray lubrication systems aid users in reducing their ecological footprint, as the systems are able to work with high-frequency valves without the use of compressed air, ensuring a precise and mist-free application of oil.

It also negates the need for an extraction system and ensures that no oil that could otherwise enter the production environment is wasted, while also reducing the need for machine cleaning and maintenance work.

technotrans will present a robust variant of the spray.xact c, which features a double-wall housing structure and spray lubrication width of up to 2 000 mm.

Kosciesza explains that this variant is designed to meet demanding requirements that call for a high level of stability and resistance, such as in cold rolling processes where impact could occur.

Additional collision protection is possible in the form of specific structures where the upper housing half can be moved vertically by up to 300 mm, creating more space for coils passing through.

Visitors to the Blechexpo will be able to explore the spray.xact metal, featuring a patented nozzle technology with the capability of spraying quantities as low as 0.5 g/m2 of oil, without using compressed air.

He elaborates that this will allow high-viscosity oils to be supplied evenly to blanks coils. The high-frequency pulses of the spray valves ensure a gap-free application preventing material damage.

The application of hot metals to coils for effective protection against corrosion is another key element of the exhibition, with technotrans able to provide users with a new system solution comprising temperature control and spray lubrication.

“We control the temperature of the entire system, including the line system and spray valves, to ensure that the substance is applied to the coils with precision and in a resource-preserving manner. Cured at ambient air, hot melts provide optimum protection against environmental influences,” explains Kosciesza.

He adds that technotrans will also be presenting its spray lubrication systems for a variety of application areas, including the spray.xact easy, an inexpensive solution for straightforward metalworking applications, which is adjustable for the applied type and quantity of oil.

Meanwhile, the spray.xact reflection, designed for the indirect oil lubrication of coils of high-speed blanking presses – where typically small electronic components, such as plug contacts, are sprayed with ultrathin films of oil – will also be on display.

Edited by: Nadine James

Features Deputy Editor

EMAIL THIS ARTICLE SAVE THIS ARTICLE

ARTICLE ENQUIRY

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here