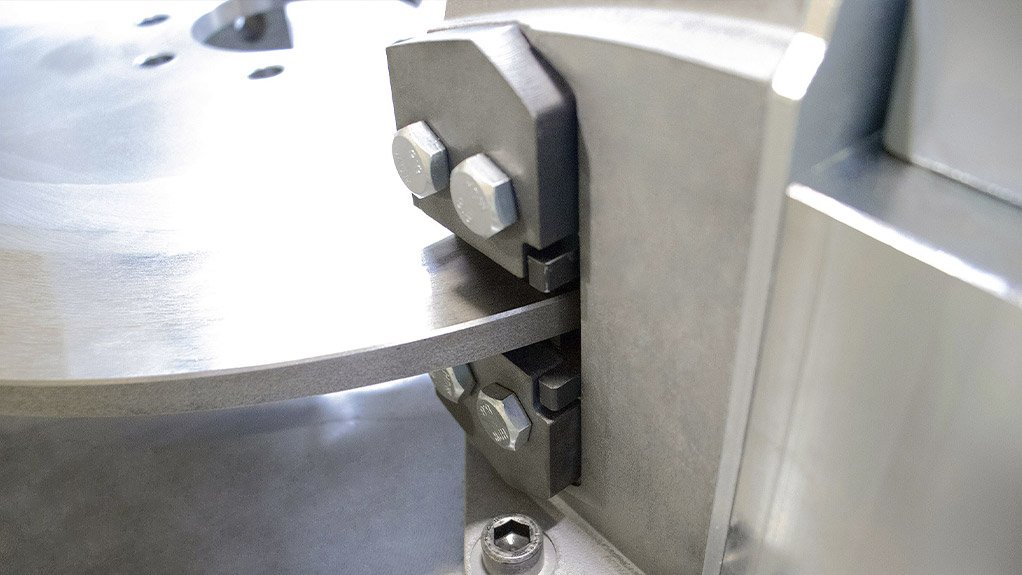

The new MV industrial brake series from power transmission component manufacturer and distributor RINGSPANN South Africa has an innovative locking mechanism and applies clamping forces of up to 25 000 N to the disc.

The MV series offers higher braking forces with compact dimensions, as well as automatic wear adjustment, and is reported to exceed technical limits of existing brakes.

“The comparable sizes of the new MV brakes will produce more clamping force at a significantly lower weight,” says RINGSPANN South Africa GM Dirk van Niekerk.

This will allow for more switching cycles per hour and offers a substantially higher B10d value – the number of operating cycles after which 10% of the population of a component will have failed dangerously.

The new MV brakes now enable clients to use a spring-applied, electromagnetically released brake in various applications for which there was previously no suitable electromagnetically released brake.

“Owing to their compact design and high-power density, the brakes can be used in countless applications as a holding brake, a service brake or an emergency stop brake,” says Van Niekerk.

The MV series is designed with notable clamping forces and is available as standard for brake disc diameters from 30 cm to 71 cm and covers a range of various stopping and deceleration applications in mechanical and plant engineering.

“Their specific fields of application include machine tool construction; turbine, fan and blower technology; winch and winding technology; the wind power industry; and general drive technology,” he explains.

They are particularly attractive for designers who want to spare users and operators the high installation and maintenance costs of hydraulic and pneumatic brake systems.

Van Niekerk adds that high switching rates create extended performance and flexibility potential for users, while their energy requirements are minimal.

Additionally, the brakes have intelligent electronics and work with a highly efficient closing mechanism.

Further, RINGSPANN offers the new MV disc brakes from alternating current 220 V to 240 V and 380 V to 480 V.

“In terms of energy efficiency, the brakes build on the excellent values of the EV and EH series,” Van Niekerk enthuses.

Additionally, an inductive encoder for sensory monitoring of the brake function can also be attached as an option, in the open and closed position, to monitor the degree of wear of the brake pad.

Further, friction block replacement is done in a few simple steps and without dismantling the brake. Braking torque and clamping force can be easily and precisely adjusted to the application using an adjusting nut.

The company has also ensured that the sensor-monitoring functions can be integrated into higher-level safety and control systems.

All these are important contributions to improving the efficiency, operational safety and availability of industrial drive systems, says Van Niekerk.

In addition to its previous portfolio of electric disc brakes, RINGSPANN can now provide designers of drive systems with six further basic types of innovative e-brakes in the new MV series.

The brakes are available in the frame sizes of 022, 033 and 044, with clamping forces from 4 kN to 25 kN, and can be used in an array of applications.

RINGSPANN offers the new MV brakes in versions with manual wear adjustment, as well as a variant with automatic wear adjustment, known as the “FEA” design.

While manual adjustment is primarily suitable for holding applications or applications with rather infrequent braking, automatic wear adjustment is primarily recommended for service brakes with demanding deceleration tasks.

“Owing to the MV series’ high performance, clients have already expressed great interest in it,” Van Niekerk concludes.

Edited by: Zandile Mavuso

Creamer Media Senior Deputy Editor: Features

EMAIL THIS ARTICLE SAVE THIS ARTICLE

ARTICLE ENQUIRY

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here