A new rock drill that promises greater reliability, reduced operating costs and improved productivity, has recently been launched.

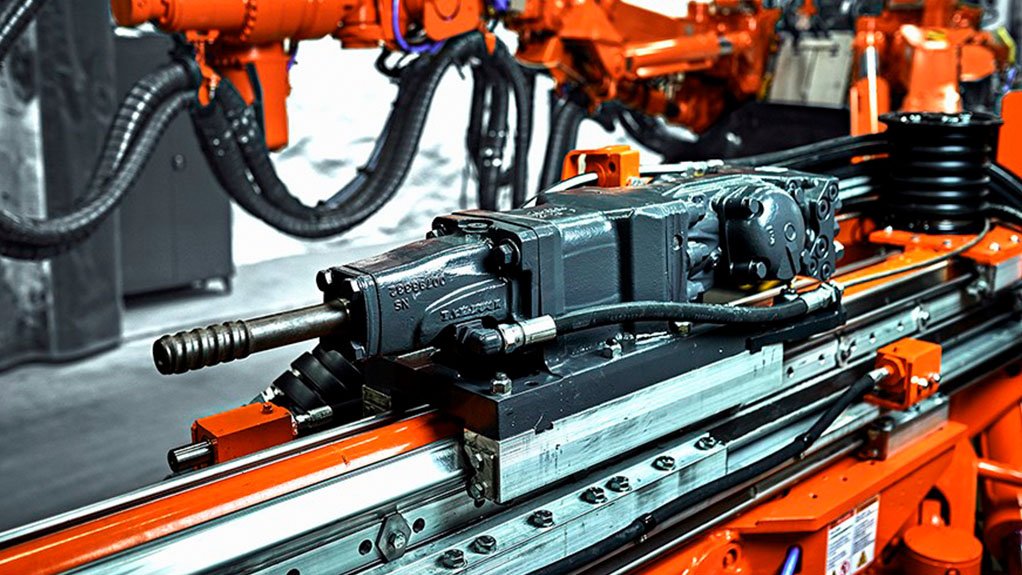

The RDX5 rock drill from Swedish mining gear and metal-cutting tools maker Sandvik, features new design aspects such as pressurised seams to increase durability. The drill is designed with a minimal number of moving parts, aimed at helping to increase service intervals.

The new RDX5 is interchangeable with the company’s current HLX5 rock drills and is compatible with all equipment and applications related to the HLX5. There is no need for any additional installation kits for equipment that houses the HLX5 rock drill and improvements in design and material used in the new rock drill are said to enhance the HLX5’s qualities.

The company also announced that it will soon introduce a new XL rock drill for large-top hammer drilling, allowing operators to expand hole size. A rock drill equipped for high-altitude operations will also be available.

The company explains that major functional groups are continuously upgraded and redesigned to improve reliability and service life.

Sandvik’s Rock Drill Innovation Centre facilitates continuous development and re-modelling of drills, equipment and features, while its field tester laboratory confirms the quality of its rock drill service.

The test laboratory is housed in a purpose-built container, making it moveable and applicable for either indoor or outdoor locations, providing automated test reports, general condition data and data on internal components.

EMAIL THIS ARTICLE SAVE THIS ARTICLE

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here