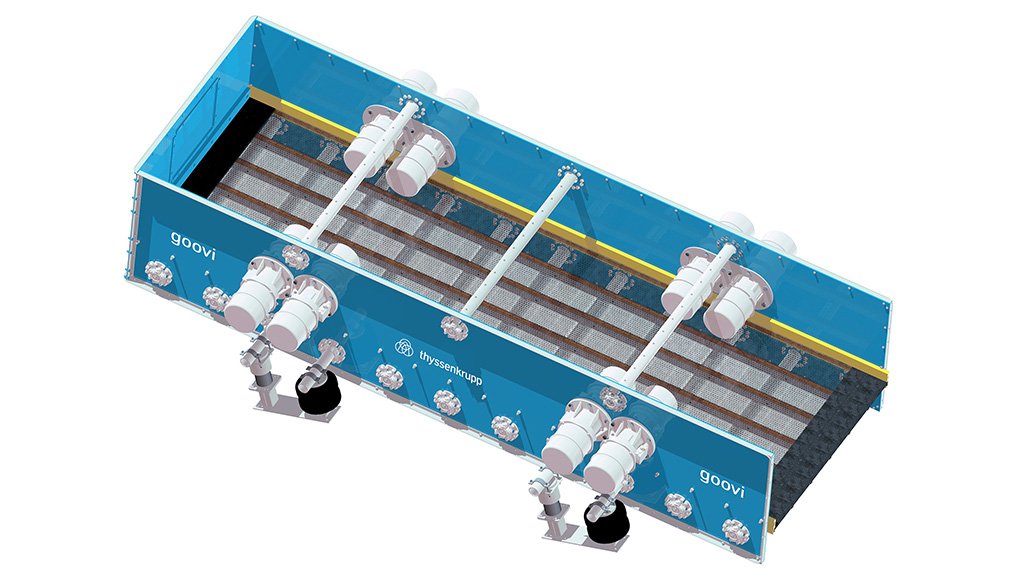

A recently developed multi vibrating screen features new patented drive technology in combination with an innovative control system that is said to provide a significant increase in operational flexibility, product quality and performance, coupled with greatly reduced weight and height.

The goovi multi vibrating screen from thyssenkrupp Industrial Solutions is particularly suited for use in vibrations in secondary and tertiary screening in the gravel and crushed stone, mining, mineral processing and recycling industries.

“With the goovi, all vibration modes (circular, linear and elliptical) can be realized in one machine, allowing flexible adaptation to changing job requirements and material properties. In addition, the low height of the goovi facilitates simple installation in existing plants,” says thyssenkrupp Mining Technologies head of product line screens and feeders Achim Schönfelder.

The new screen is driven at four different points, one on each side, front and back, resulting in an optimum stress distribution in the side walls. It also uses fewer rotating parts than conventional screens, which translates into significantly lower weight and height as well as reduced maintenance and wear. Two or three standard unbalance motors are installed at each drive point, so each goovi screen is driven by a total of 8 or 12 motors, depending on size, which are synchronized by means of a patented programmable logic controller, supplied with the machine.

The patented control system is designed to allow speed and flow direction to be seamlessly adjusted so that all important operating parameters can be optimally adapted to the requirements of production at any time. In addition, the design aims to allow for flexibility to adapt to changes in material properties, such as moisture, during operation and to optimise the processing of difficult-to-screen materials.

Different product qualities can be saved in recipes and retrieved as required, with the use of the touchscreen supplied. The multi vibrating screen can also be integrated into control loops for product optimisation. There is a preset cleaning function for the removal of clogged particles. The unit is fully digitised and can be integrated into a higher-level control system, paving the way for Industry 4.0 in processing plants.

“To optimise costs and delivery times, thyssenkrupp has developed a range of standard machines. The single-deck and double-deck versions are available in six different widths and four different lengths with a maximum screening area of 26 m². However, due to the straightforward modular design, custom solutions tailored to a particular application can also be supplied,” adds thyssenkrupp Mining Technologies product manager screens Peter Berlitz.

EMAIL THIS ARTICLE SAVE THIS ARTICLE

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here