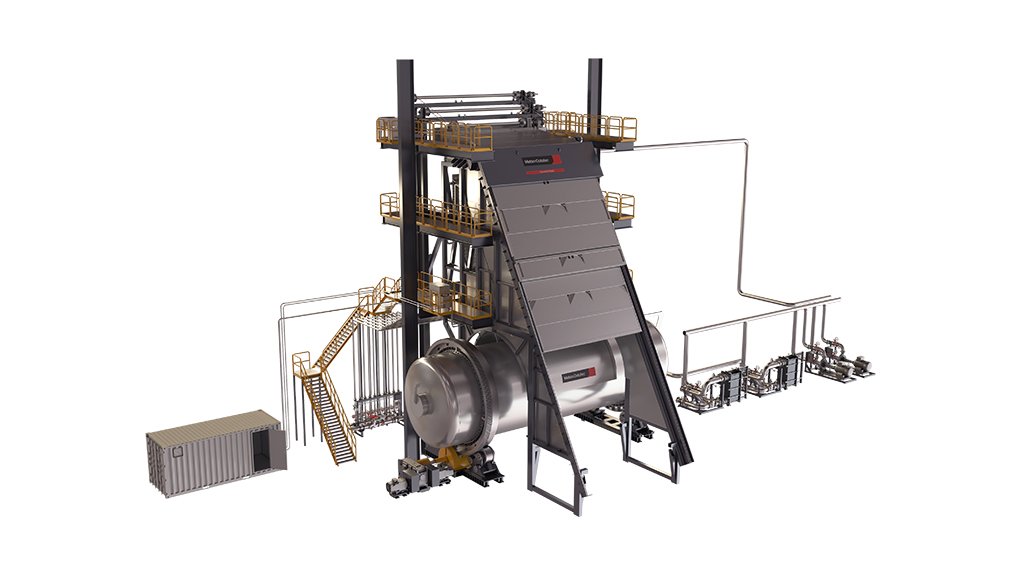

A new modular converter hood system for horizontal converter vessels used in the smelting process promises a sulfur dioxide (SO2) gas capture capability of 99%, minimizing the environmental impact.

The new system from Metso Outotec Corporation is suitable for greenfield and brownfield installations and features a modular design to enable quick on-site assembly, with minimum plant downtime.

“Besides its excellent gas capture capability, the system design ensures a well-controlled ingress air flow that improves process gas quality. The primary converter hood’s advanced water-cooling system increases process reliability and improves safety in the converter aisle, while also reducing maintenance needs and prolonging equipment lifetime,” explains Metso Outotec director precious metals Jonny Eliasson.

The company highlights several benefits of the system, including:

- Excellent SO2 gas capture for outstanding environmental performance

- Improved safety in the converter aisle

- Well-controlled ingress air flow for improved process gas quality

- Prolonged equipment lifetime thanks to the design and advanced water-cooling system

- Reliable operation with low maintenance needs

- Easy on-site assembly and short installation time thanks to modular design

- Backed by expert service and support

Metso Outotec provides support during commissioning of the Converter Hood System and also offers comprehensive training for operators and management as well as ongoing technical support and service as part of a service agreement.

EMAIL THIS ARTICLE SAVE THIS ARTICLE

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here