While the South African mining industry in many aspects is leading the country’s Fourth Industrial Revolution (4IR), the manufacturing sector is not as quick to adopt to new ways of working and the use of technology, says professional services firm PwC South Africa industrial manufacturing and digital operations lead Pieter Theron.

PwC has conducted several studies over the years that indicate that local manufacturers show less intent than their international counterparts to use technology and adopt new ways of working to enhance their operations.

As some local industries are protected by safeguard duties, such as those on steel imports for example, Theron believes that the manufacturing sector’s needs to embrace a desire for global competitiveness at a far greater rate.

“It is as if we have lost our competitive edge and the country’s manufacturing companies need to improve their processes beyond the traditional engineering approaches. It is almost like the deindustrialisation of the South African economy,” he quips, adding that perhaps the country cannot be globally competitive without some protection from government.

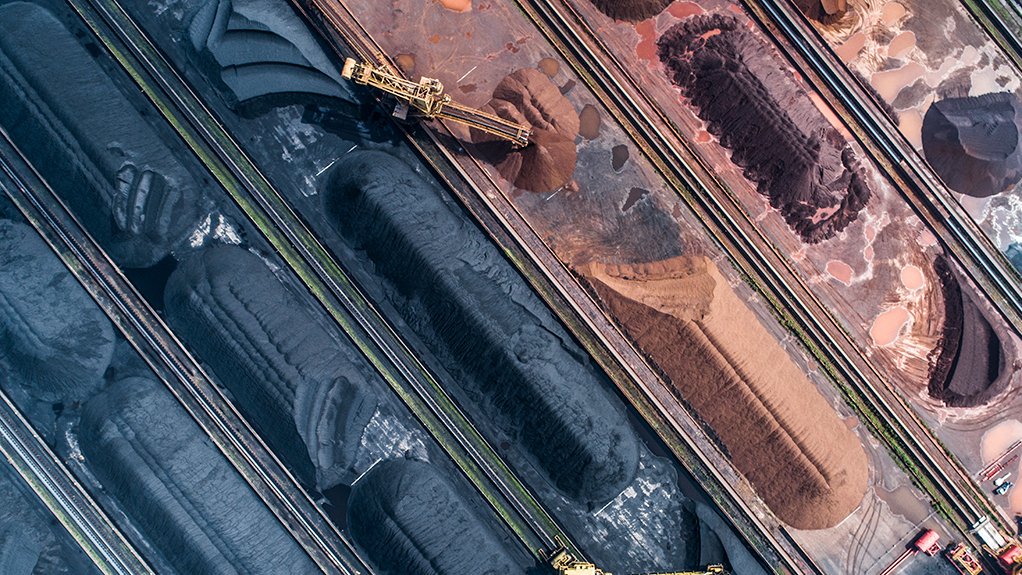

Conversely, the mining industry has been eager to adopt 4IR technology, especially innovations regarding safety such as proximity detection systems for example. Safety is an important aspect in the mining industry, with mines aiming to achieve or maintain zero harm targets, prompting their investment in regard but also conscious efforts to become more productive using technology and new ways of working.

“There has also been a commodity price boom of late, so there is money for such investments, but the mining sector’s investment in 4IR technologies started before this upturn, with PwC working on digital strategies for mining houses in 2018 to unlock their digital transformations,” states Theron.

With the move away from deep-level mining in South Africa, mines want to boost the efficiency of their operations above ground as well as to be more globally competitive and improve their margins and this is leading the new cycle of investment.

Consequently, one of the business cases PwC is working on for a major mining company involves preventing lost blasts, which directly impacts on productivity and profitability.

“The company is investing in 4IR technology to address such challenges purely for returns, which are estimated to be in the millions,” notes Theron.

Knowledge is Power

PwC continuously conducts research on the progress of 4IR in South Africa to determine what does and what does not work, he notes, highlighting last year’s publication of the ‘10 insights into 4IR – the state of digital transformation in the South African mining industry: PwC and the Minerals Council South Africa’ report.

Since 2016, PwC has also been conducting a biannual research piece on the level of progress of the 4IR, with the last two publications in 2018 and 2020 each including 50 South African companies.

“We hope to include this many local companies again this year,” says Theron.

Following engagement with its clients, PwC has determined that companies often believe that the 4IR is all about technology, failing to see the bigger picture that it is actually about a new way of working, he adds.

“We work with our clients to determine what they should invest in to realise great returns. For example, we have developed a digital strategy and roadmap for a large industrial company operating on several continents that will realise a return of more than $10-million a year.”

Digital Means Faster Decisions

Traditionally, capital investment takes a long time, whereas digital investment involves a different way of thinking. It needs to be agile and is about implementing decisions more quickly.

That is why digital governance within an organisation is so important, adds Theron.

“Depending on an organisation’s maturity, it can almost become a separate decision-making entity in an organisation that will look at digital investments and fast track capital approval, monitor the progress astutely and, if it is successful, rapidly scale the 4IR project throughout the organisation.”

PwC often comes across clients that have been busy with 4IR pilot projects for three years, while some of their peers have conducted pilots and rolled out projects throughout their organisations in 18 months and are already banking the benefits.

PwC’s approach to those reluctant to adopt 4IR technology is always business-case driven, states Theron.

“In local manufacturing, the traditional aspects, such as good operations management practice, are implemented in some form or another but people have not started to rethink their practices.

Edited by: Zandile Mavuso

Creamer Media Senior Deputy Editor: Features

EMAIL THIS ARTICLE SAVE THIS ARTICLE

ARTICLE ENQUIRY

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here