The reception to screening solutions provider Sandvik Rock Processing’s entry into the screening media market in Africa has been positive, said Africa regional manager for screening media and wear protection Phumelele Motsamai.

Speaking to Mining Weekly on the company’s progress at this year’s Electra Mining Africa, held last month, she attributed the success to Sandvik’s strong brand and established presence in Africa – particularly in remote areas where coverage from other providers is lacking – and its offering customers a new competitive option for screening solutions.

Screening media may represent a minor cost when compared to the larger capital equipment used in mining, but it is a critical component that can significantly impact on productivity and profitability, emphasised Motsamai.

“Screening media plays a critical role in optimising productivity and material quality in mining and quarrying. Sandvik Rock Processing recognises the uniqueness of each operation and always seeks to address the specific requirements to ensure the improvement of operations.”

Motsamai added that, traditionally, customers have been concerned about the lack of access to screening media and, ultimately, the lack of support in some African regions.

She was confident that, with four entities in Southern Africa and a total of 11 across Africa, Sandvik Rock Processing has the necessary touchpoints to keep stock close to customers, which reduces lead times and increases uptime.

The company’s move into screening media was also driven by the need to provide more comprehensive solutions for customers. Already a well-established producer of mining and construction screens, Sandvik Rock Processing recognised the importance of adding screening media to complete its product lineup.

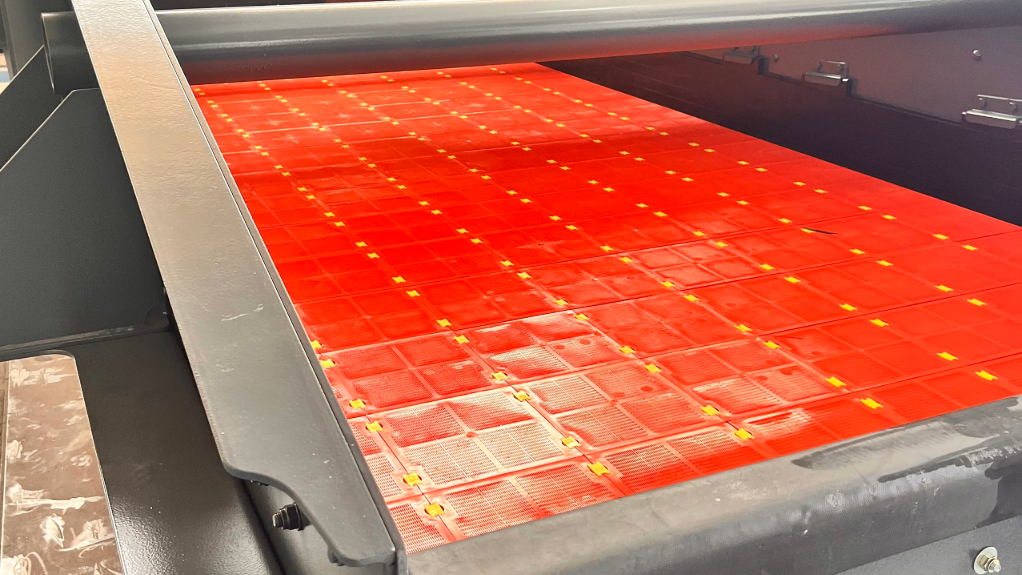

By combining advanced technology with a deep understanding of customer requirements, the company offers a variety of screening media products, including polyurethane, rubber and wedgewire panels, all designed to handle the harsh conditions of mining applications.

These products aim to ensure that operations run smoothly with less downtime.

Sandvik also provides a broad range of wear protection solutions to extend equipment life.

Tailored Solutions

Among the products in Sandvik’s wear protection range is the HX900 cast-in-carbide wear plates that use recycled tungsten drill bits, which are embedded in nodular cast iron to combine flexibility with improved wear resistance.

This eco-friendly solution aligns with Sandvik’s sustainability goals by repurposing materials that would otherwise be discarded, adds Motsamai.

By repurposing 100% of in-house recycled drill bits for use in wear plates, the company not only reduces waste, but also lowers energy consumption by 70%, and overall carbon emissions by 40%.

The product has been well received and is expected to enable new opportunities in the African market, she said.

Motsamai further describes the HX900 as “the shining star” of Sandvik’s product range, noting that trials have shown it to “far outlast” any other wear protection solution currently on the market.

She emphasised the company’s commitment to working closely with customers to develop solutions that address specific challenges: “Our customers are not just looking for products that will last – they also want to reduce downtime and ensure that operations remain productive.”

This focus on long-term value has resonated with Sandvik customers, who appreciate the company‘s ability to reduce operational disruptions while benefiting from a more sustainable product.

Sandvik Rock Processing’s entry into the screening media market represents just one part of the company’s broader strategy to expand its footprint in Africa.

With its global supply chain and extensive presence across the continent, the company is well positioned to continue providing innovative solutions that improve efficiency and productivity for mining operations in Africa, said Motsamai.

She was optimistic about the potential for growth: “We are really looking forward to getting out there, taking the market by storm and helping our customers with comprehensive solutions that cover all aspects of their operations, from underground to surface, crushing to screening. With Sandvik, they have one supplier who can support them every step of the way”.

Edited by: Donna Slater

Features Deputy Editor and Chief Photographer

EMAIL THIS ARTICLE SAVE THIS ARTICLE

ARTICLE ENQUIRY

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here