Engineering consultancy Lubrication Engineers (LE) plans to unveil some of its advancements in industrial lubrication technology at this year’s Electra Mining Africa exhibition and conference, set to take place from September 2 to 6, in Johannesburg.

Central to this showcasing will be the introduction of EasyBar, a solid bar lubrication solution designed specifically for rotary kiln tyre bores and industrial ovens.

The company’s primary focus will be to demonstrate the tangible benefits of EasyBar in industrial settings, particularly its streamlining of maintenance procedures and improved equipment reliability, says MD Colin Ford.

The solution integrates LE’s proprietary EP additive Almasol, which enhances wear protection and operational efficiency.

Ford explains that traditional methods of lubricating rotary kiln tyres, such as spray-on applications, have long been criticised for safety risks, including toxic fumes and potential fire hazards.

Often, these methods also resulted in inaccurate application of graphite and oil mixtures, posing challenges in controlling the amount of graphite applied to the tyre surface.

In contrast, Ford says EasyBar offers a solid, nontoxic lubrication solution that melts and evenly distributes within the tyre bore. This approach not only extends the lifespan of wear pads but also significantly enhances operational safety by eliminating toxic fumes and the risk of flash fires.

“The simplicity of solid bar lubrication requires no machinery for precise application, making it a safer and more effective choice for maintaining rotary kiln tyres and riding rings.”

The company aims to offer a reliable, environment-friendly solution that meets industry standards for sustainable lubrication practices, he adds.

The EasyBar solution is available in different sizes so that small and large kilns need to use only one EasyBar for a weekly application.

Further, LE will also showcase the rest of its range of lubrication solutions tailored for diverse industrial applications at Electra Mining Africa. This includes its Pyroshield synthetic open gear lubricants, Duolec industrial gear lubricants and synthetic industrial oils – all of which have been engineered to optimise performance and longevity.

Visitors to LE’s stand can also expect to see a comprehensive display of LE’s capabilities, including the company’s Bluetooth-enabled single-point lubricator systems, and improved product formulations for various mining and industrial applications.

Ford expects that the company’s Bluetooth single-point lubricators will attract interest, as they have the potential to improve occupational health and safety on mining and other sites.

“Essentially, the operator doesn’t have to shut down the equipment and manually apply the lubricant. They can stand outside the cage and manage the application from their phone,” he says, adding that this is much safer, with less downtime and better productivity.

LE will also have its asset reliability solutions on display, encompassing the full lubrication storage and management cycle.

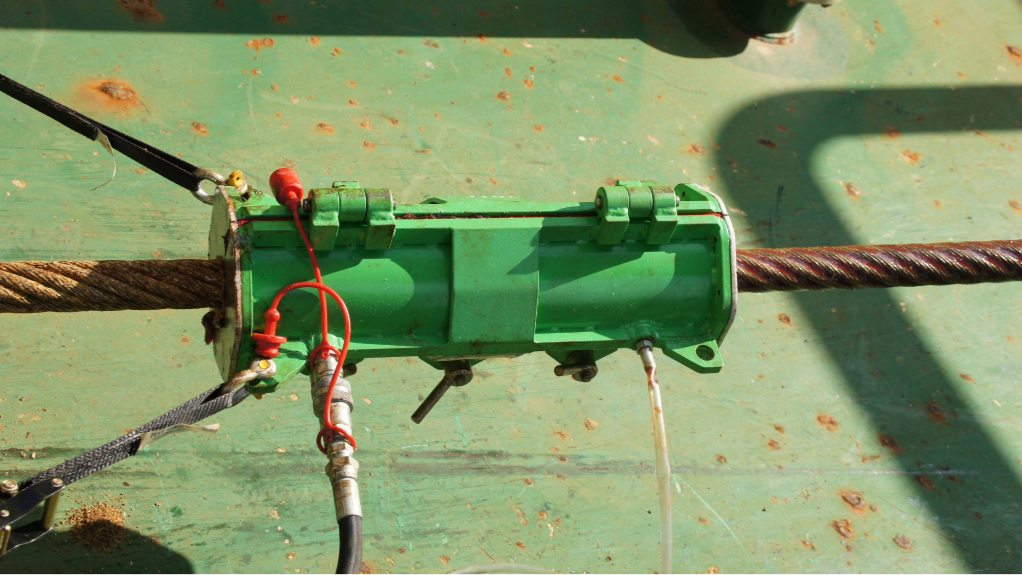

A large portion of the stand will be dedicated to wire rope lubrication, where visitors can find out more about the Viper range, as well as LE’s Wirelife product.

LE’s teams from the US, where the company is headquartered, and Australia, will also be available to provide technical insights and discuss the latest advancements in lubrication technology.

Edited by: Nadine James

Features Deputy Editor

EMAIL THIS ARTICLE SAVE THIS ARTICLE

ARTICLE ENQUIRY

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here