Leading automotive and industrial products manufacturer G.U.D Holdings’ subsidiary, Indy Oil, has opened its analytical centre at its blending plant in Pietermaritzburg, KwaZulu-Natal.

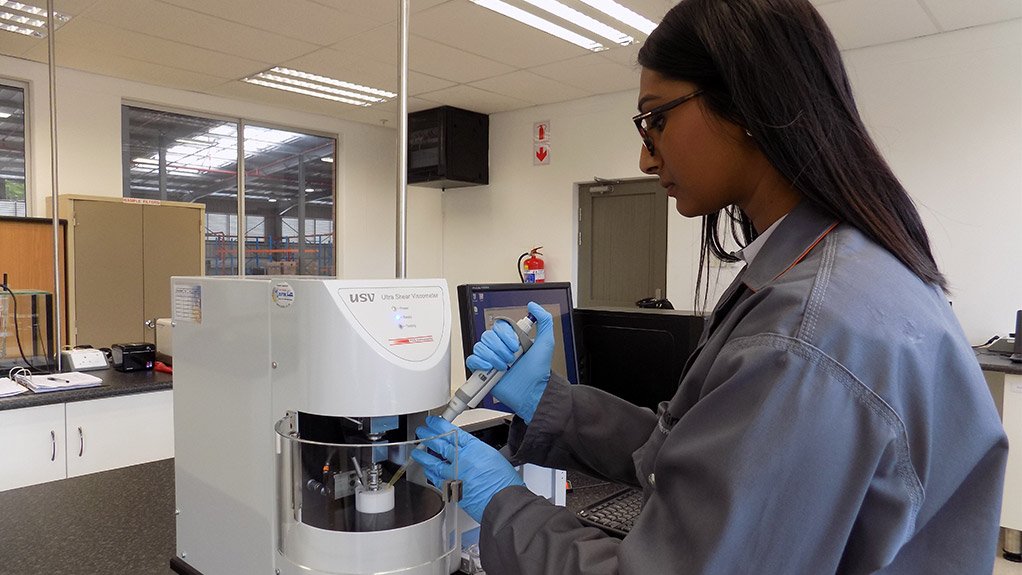

With the 75 m2 laboratory having opened officially in November, it features high- technology lubricant testing equipment, including an ultra-shear viscometer (USV), which G.U.D. Holdings technical director Alex van den Blink says is a first in South Africa. It is used to test the viscosity performance of Indy Oil’s engine lubricants against the high speed and temperature demands that lubricants are exposed to in a modern engine.

The main application for the USV is in the research and development (R&D) of engine oils and additive packages. Its ability to automatically measure viscosity at different temperatures and shear rates means that researchers can fully characterise a candidate lubricant with little or no user intervention required – eliminating the need for field trials.

USV Benefits

Modern automotive engines run at increasingly higher speeds and temperatures, placing ever greater demands on engine lubricant performance, while there is a need for these engines to operate with lower viscosity lubricants to reduce frictional losses and increase overall efficiency, G.U.D Holdings lubricants technical manager Jayne Bhanjan tells Engineering News.

As a result, the shear rates encountered in the main engine bearings have risen significantly and far exceed the capabilities of traditional viscometers. The USV can assist the lubricant formulator by generating viscosity – temperature maps for high-performance oils over a range of shear rates.

While the high quality in high shear rate viscometry has remained at about one-million reciprocal second for many years, developments in engine and lubricant technology mean that in-service conditions are more likely operating at ten-million reciprocal seconds.

The USV can measure viscosity at these high shear rates using a novel, patented measurement technique, which avoids the problem of shear heating encountered when using conventional steady-state viscometers by subjecting the test lubricant only to the high shear rate for a short time so that the oil film temperature does not change signifi- cantly. Bhanjan points out that this concept allows for measurements to be made at much higher shear rates.

“We are also excited about our new inductively coupled plasma optical emission spectrometer, which is a highly sophisticated instrument that is rare in South African laboratories. The instrument allows for metal analysis to be done, aiding in oil- condition monitoring programmes that require component wear and fatigue to be regularly checked,” says Van den Blink.

Indy Oil’s investment in advanced equipment of this kind attests to its commitment to offer a premium-quality product that is blended and tested to meet original- equipment manufacturers’ specifications and international lubricant and chemical standards approval.

Capabilities Expanded

The company also boasts other equipment and capabilities in the centre, including ultrasonic vocalisations, inductively coupled plasma optical emission spectrometry, Oil Titrino for total acid number and total base number, a Karl Fischer coulometer, Fourier-transform infrared spectroscopy, and an automated kinematic viscometer.

The acquisition of these high-end instruments enables Indy Oil to continue with analysis and R&D with ease and accuracy to ensure that superior-quality products are produced and that Indy Oil remains at the forefront of lubricant technology.

Van den Blink notes that the analytical centre will play a significant role in the development of the company’s automotive and industrial product range, and entrench the Indy Oil brand locally and globally.

Need for Analysis

Bhanjan notes that oils and/or lubricant analysis for quality control is an integral part of the manufacturing process and must be carried out with stringent controls to ensure accuracy, repeatability of process and reproducibility of results, which the centre enables.

“The concept of having a technologically advanced analytical centre arose to support the R&D and manufacturing processes of Indy Oil, ensuring that our products meet the highest standards.”

She adds that the capability of carrying out analysis on site and independently assists in improving efficiencies and throughput for Indy Oil.

The analytical centre has been beneficial for production and quality control, as all analysis regarding the verification of raw materials can now be done in-house to the highest standards.

Additionally, all finished products are then tested and verified to ensure that they conform to the specifications stipulated by the lubricant industry.

“Owing to the nature of the performance requirements of ever-changing automotive and industrial technologies, oil and lubricant manufacturers need to ensure that their base and additive components are in line with technology changes while considering existing technologies that have not yet become obsolete in certain markets,” avers Bhanjan.

Edited by: Zandile Mavuso

Creamer Media Senior Deputy Editor: Features

EMAIL THIS ARTICLE SAVE THIS ARTICLE

ARTICLE ENQUIRY

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here