There is a risk associated with buying capital equipment, and the choice of a factory crane can be “especially tricky”, says local overhead cranes and hoists manufacturer Condra Cranes. Condra advises to look at the following elements: the cost of downtime, inherent strength, and the design expertise of manufacturers.

The company offers advice on how to “ease the buying process” while reducing the risk, commenting that the first step is to evaluate the cost in terms of production lost in the event of a breakdown.

The cost of downtime is, generally, “always high”, with the possibility of becoming “staggering” if equipment is left idle while staff wait for components that have long shipping times.

The company, therefore, suggests that spare parts and technical support be locally, and immediately, available, to shorten the duration of the breakdown.

Companies should question crane suppliers on their spare parts holdings, where these parts are stocked and the probable time delay between a breakdown and spare parts arrival, especially if they have to be imported.

Condra guarantees the delivery of its spare parts within 48 hours in South Africa, and in five days for the rest of Africa.

However, it notes that, if an issue arises – such as a breakdown that requires the replacement of parts such as the carriage or crab – the shipping time, production loss and associated costs will vary.

In relation to breakdowns, the second element is the degree to which the crane might be described as robust, as this becomes important when the “heavy-handed nature” of operators is a factor.

Condra MD Marc Kleiner highlights that the local environment tends to be less forgiving than those in Europe, which results in more strain on the strength of the crane’s build.

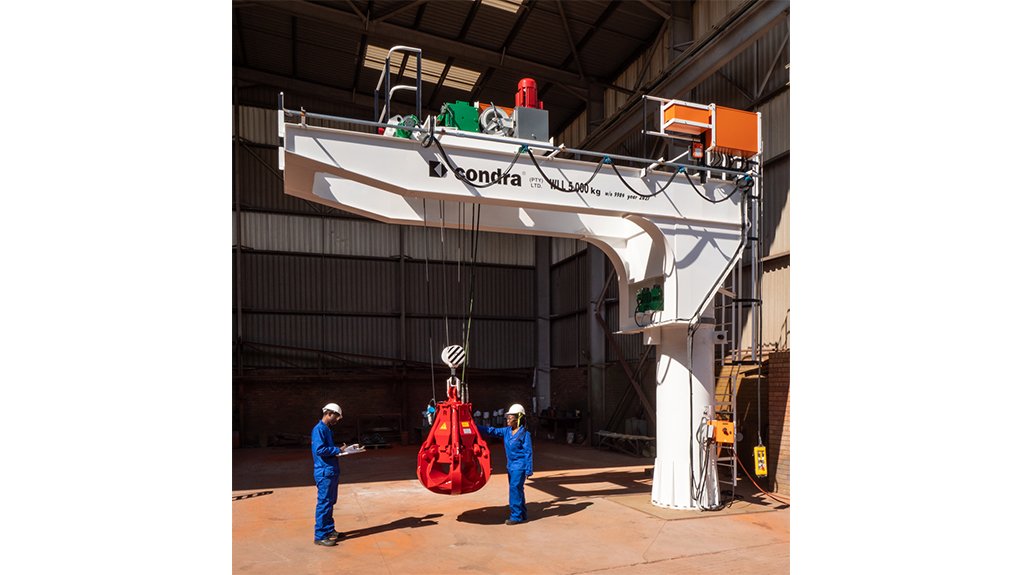

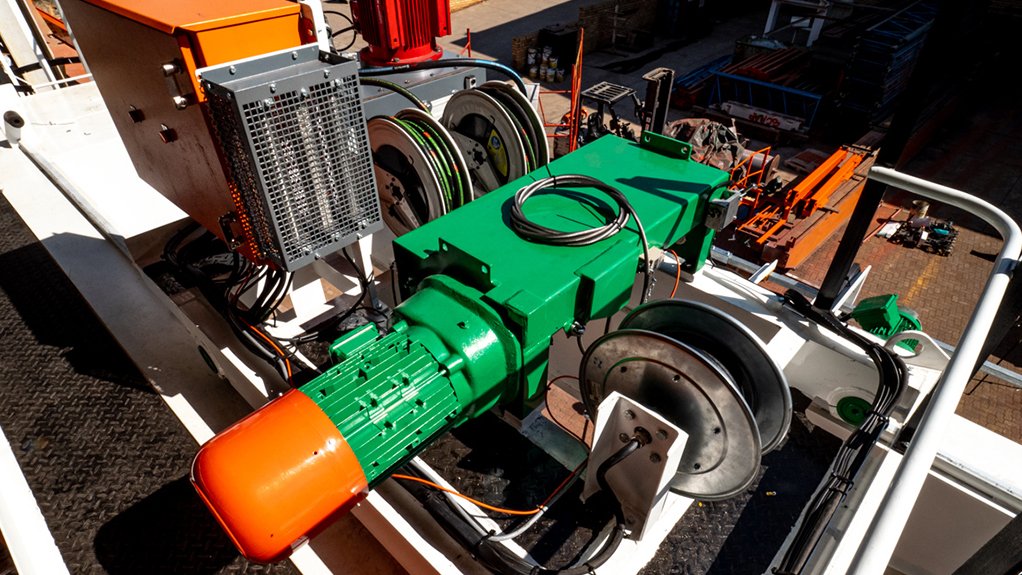

Therefore, Condra addresses the issue by following a design philosophy that focuses on strength and durability, with the company leveraging its expertise by delivering mechanical reliability amid corrosive and abrasive environments, extreme temperatures, humidity and altitudes.

Its “adaptable” product range derives from the modular nature of its cranes and hoists, with every crane being designed and assembled according to the customer’s specific application, using a variety of components, says Kleiner.

Manual and/or electrical operation is an option offered by most crane manufacturers, with Condra offering automation across its product range while providing “impeccable products, parts and localised servicing”.

The third element is design expertise, as all original-equipment manufacturers design in-house.

Consequently, it is important to know where such expertise is located, as if the manufacturer is based in either Europe or China, then African customers will not have easy access to qualified consultation.

Condra, however, claims to have advanced levels of design flexibility and staff availability.

The company’s design office, based in Johannesburg, is easily accessible to African customers, consequently allowing for face-to-face liaisons between the design office and customers.

Further Condra says that what sets it apart is its network of authorised agents, which enables the company to delegate responsibility for technical service to the respective agents, all of which are private engineering or crane companies.

“Most multinational companies don’t do this. Instead, when end-users need technical support, the customer must contact one of the company branches, which then contacts head office to find out which agent to use,” Kleiner explains.

Such a technician often has no prior working experience with a customer’s specific crane, whereas Condra puts end-users directly in touch with a dedicated service agent from the time the crane is commissioned.

Kleiner adds that, from that time onwards, the agent is responsible for all routine servicing and additional technical support, which means that the need to approach Condra’s head office for assistance is “exceedingly rare”.

“This approach helps to dramatically reduce crane downtime. An additional benefit is that a close rapport develops between the end-user and the agent’s technical team. It is a superior service system,” he declares.

Customers should “think prior to buying” and do the necessary research to make a well-informed decision that will reduce downtime and costs, the company advises.

Edited by: Nadine James

Features Deputy Editor

EMAIL THIS ARTICLE SAVE THIS ARTICLE

ARTICLE ENQUIRY

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here