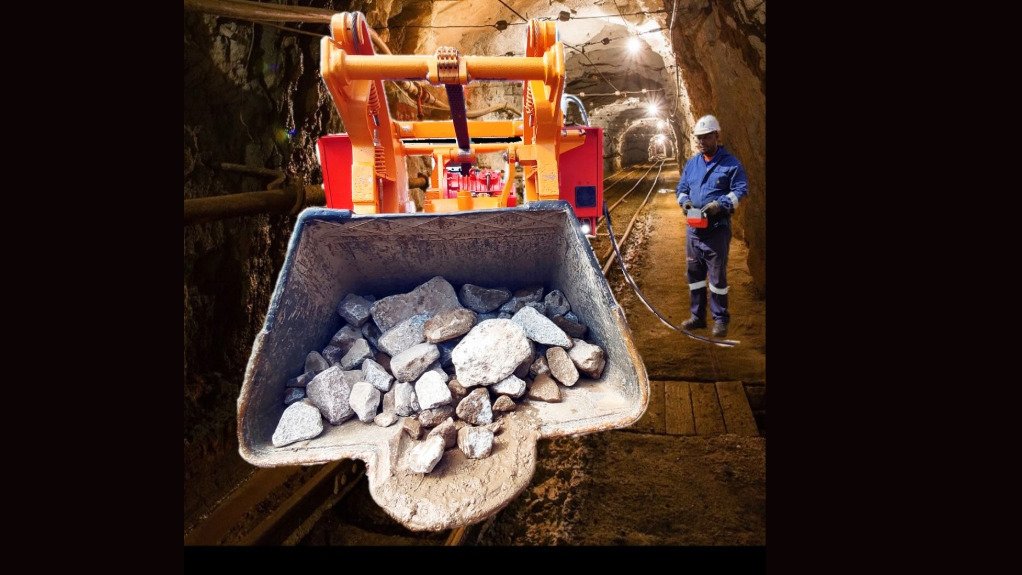

South African supplier of rail-bound throw loaders for deep-level hard rock mines Salzgitter Mzansi has recently launched three new products – the Salzgitter EL300R electric rail bound remote-controlled loader, the Salzgitter Titan electric crawler loader and the Hercules re-railer.

The company says its design initiatives and practical improvements are aimed at meeting the current challenges faced by the deep-level mining industry by helping reduce mine development costs, increasing operational efficiency, and enhancing operator safety. In particular, Salzgitter Mzansi’s EL300R remote-controlled electric loader and Hercules re-railer are described as revolutionary developments that go a long way to improving safety and helping reduce costs underground.

Part of Salzgitter Mzansi’s innovation is the conversion of its HL380U pneumatic workhorse to a high-performance fully electrical loader, namely the Salzgitter EL300R. The loader repowers a mine’s existing Salzgitter loaders, further maximising asset utilisation while also saving energy costs that would otherwise be wasted as a result of compressed air production and reticulation to loaders working far from the shaft.

Benefits of the Salzgitter EL300R include:

- Improved loading performance

- Enhanced safety and improved working conditions

- Significant energy savings

Another newly launched product is the compact and portable Salzgitter Titan, a remote-controlled fully electric crawler-mounted overhead throw loader, ideally suited to chamber and cross-cut development.

Designed with maneuverability in mind, the Salzgitter Titan can excavate chambers and crosscuts safely and cost-effectively, without the need for compressed air.

The development of wireless remote control for both Salzgitter Mzansi’s pneumatic and electric loader versions helps ensure safety of the operator, positioned behind the loader. This represents a step-change in operator safety and complements Salzgitter’s existing range of loader safety devices including its revolutionary Hercules re-railer.

Electric power facilitates the on-board acquisition, processing and transmission of loader performance metrics to the surface, as well as environmental measurements of temperature, humidity and gas levels, all of which can be captured by sensors on the loader.

Salzgitter Mzansi asserts that its new innovations fully align with the gold and platinum industries’ objectives to reduce operating costs whilst improving personnel safety and underground communication.

EMAIL THIS ARTICLE SAVE THIS ARTICLE

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here