NSP Unsgaard, a division of Lion Match Company, has commissioned a R20-million pantyliner production line at its Cape Town factory.

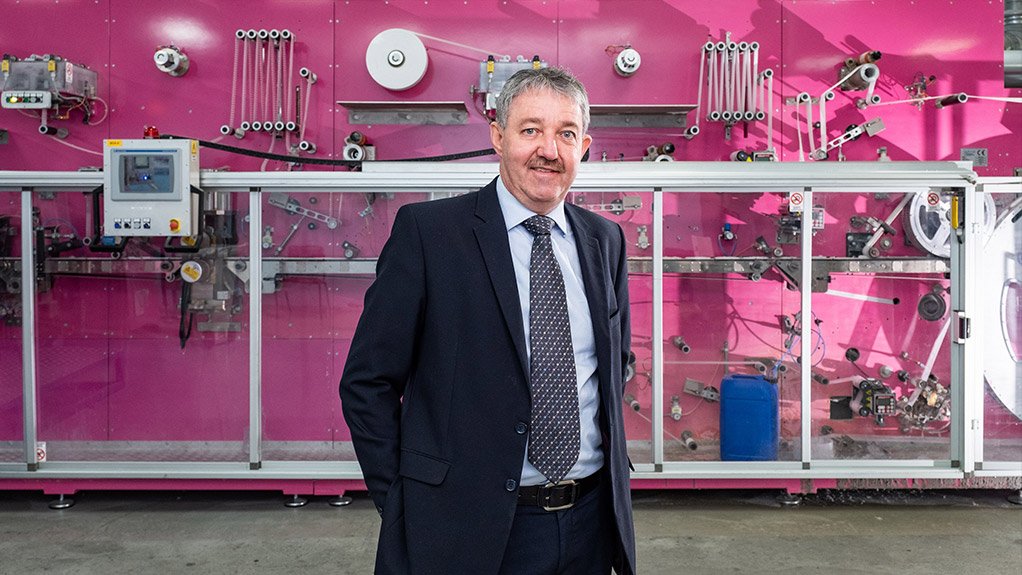

Lion Match CEO Basie van Wyk says the new equipment – dubbed “the pink lady” – is some of the most sophisticated of its kind in the country and has grown the company’s local manufacturing capacity by 55%.

This has enabled Unsgaard to both increase its sales and the category itself, while keeping tight control over working capital, quality and logistics.

Up until now, more than half of all feminine personal care products sold in South Africa have been imported.

Using older and more manual equipment, Unsgaard was previously only able to manufacture a portion of its pantyliners. The remainder was outsourced and imported.

Van Wyk points out that feminine personal care products and the pantyliner segment, in particular, is still a relatively underdeveloped segment in the feminine care space.

According to the latest Nielsen survey, Unsgaard and its Comfitex brand, is the market leader in terms of both volume and value in a category valued at R400-million a year.

This segment of the overall feminine care category is growing at 9% to 10% a year.

“This is a very competitive market. As a relatively small business compared to the large multinationals in this category, we are boxing with some of the top brands. But we are winning against them – that’s the important thing,” says Van Wyk.

He admits that the decision to invest was a calculated risk in a lacklustre economy where consumer spending is under pressure. However, the company intends benefitting from changes in consumer behaviour during tough times, gaining new customers who are looking for value for money offerings and then keeping them as the economy improves.

It is also the forerunner to further investment at Unsgaard and part of an overall investment programme that began with the installation of a R20-million line from Italy to manufacture wet wipes in 2016.

Lion Match is currently exploring buying additional machinery to manufacture sanitary pads and related products.

“We believe we can use the success on the pantyliner side and duplicate this on the feminine pad side. Here, we are still a fairly small player with a single-digit market share, so there are big opportunities to grow.

“For us, the personal care space is our growth area, and we are looking at alternatives within that space. That’s where we’ll start adding meat and becoming a big personal care player,” says Van Wyk.

The “pink lady” was engineered by an Italian manufacturer and arrived in South Africa at the end of 2017.

A lack of operator skills for such sophisticated and highly automated equipment initially led to delays in commissioning. A rigorous training programme supported by the Italian manufacturer and the adoption of a multi-skilled manufacturing approach ultimately uplifted the skills set of almost all operators in the factory.

Since commissioning, the output of the new equipment improved exponentially. It is currently running at 90% of its design capacity.

Product is more consistent, quality is high and waste has dropped by 4%.

Edited by: Creamer Media Reporter

EMAIL THIS ARTICLE SAVE THIS ARTICLE

ARTICLE ENQUIRY

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here