Local corrosion control solution provider JST in association with Total Heating Solutions, or THS, will introduce Swarm, a new corrosion-monitoring system, to the South African market next month, following its distribution agreement finalisation with US-based corrosion and erosion monitoring technology provider Cosasco in March.

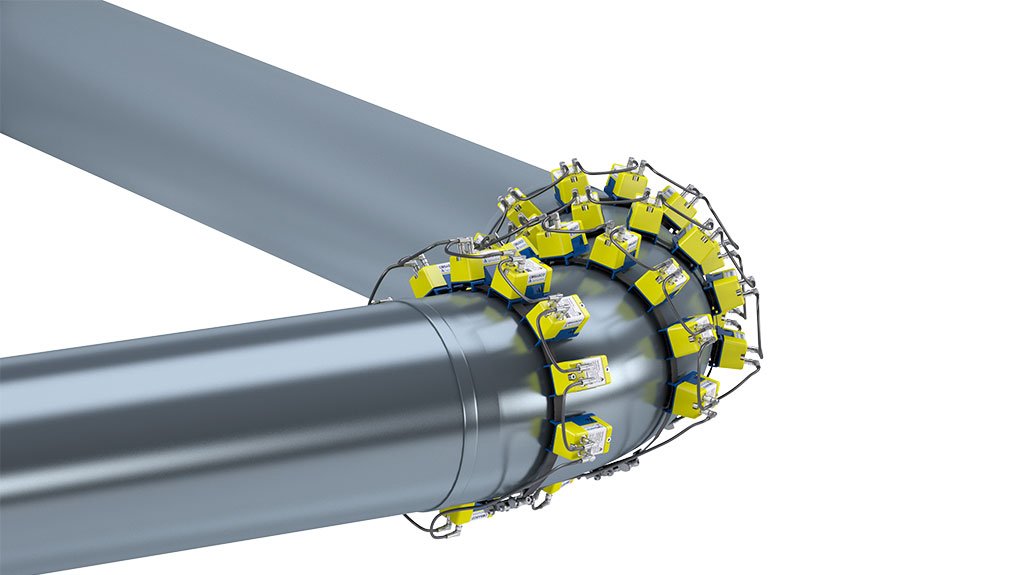

Swarm is a high-resolution ultrasonic corrosion- and erosion-monitoring system, which provides rapid response for wall thickness changes in pipelines, topsides and vessels. It is non-intrusive, installed and operated without interfering with asset production, states JST business development manager Iain Cockin.

Cosasco is planning a business visit to South Africa to provide live demonstrations of Swarm in collaboration with JST and THS. These demonstrations will take place next month in Secunda, Mpumalanga; Sasolburg, Free State; and Durban, KwaZulu-Natal, as JST has identified these locations to have industries, such as refineries, which could benefit from Swarm.

The system developed and manufactured in Trondheim, Norway, since last year, is designed for gas plants, refineries, chemicals and petrochemicals, water and wastewater plants, as well as mining, besides others. “Swarm multi-array sensor matrix can be retrofitted and installed simply by strapping Swarm sensors to the pipe. There is no requirement to remove coatings, no gluing, no welding and no hot-work permits required. Swarm wall-thickness monitoring is based on the well-established, ultrasonic pulse echo method, making it applicable and useful for all the above-mentioned industries,” explains Cockin.

He says the simplicity of installation is an attractive feature of this product, and clients that have been involved in the demonstration/trials kit in the US and Canada have been impressed when witnessing the real-time live data shown on screen.

Swarm provides fast, accurate and repeatable wall-thickness measurements, making it a cost-effective tool for real-time monitoring of corrosion and erosion concerns, states Cockin. When integrated with the Cosasco Microcor high-resolution non-intrusive electrical resistance probe technology, it can also be a highly effective tool to monitor the effectiveness of chemical inhibitor programmes, he adds.

Cockin mentions that Swarm has been installed globally. “There are quite a few installations in Canada, where Cosasco conducted many trials. Successful trials have led to the installation of additional Swarm units in North America. “The performance of the product has been highly rated.”

He hopes that this will be the case after the demonstrations in local refineries, as the product will complement JST’s existing range of corrosion-monitoring probes and data acquisition equipment, corrosion coatings and I-rod corrosion-resistant pipe support product portfolios.

Edited by: Zandile Mavuso

Creamer Media Senior Deputy Editor: Features

EMAIL THIS ARTICLE SAVE THIS ARTICLE

ARTICLE ENQUIRY

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here