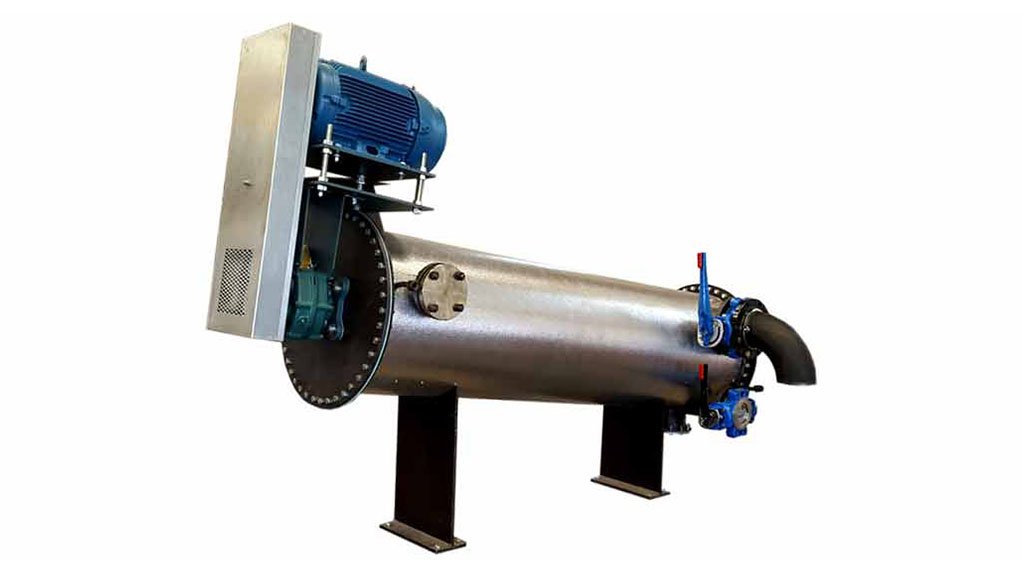

SPONSORED POST: An innovative horizontal mixing chamber that offers a solution for the effective mixing of bitumen with crumbed rubber, polymers, or any dry powder, is now available in South Africa.

D&H Equipment can build this mixing chamber into a plant customised for the specific needs of each customer, allowing for local supply of the pipework, pumps and large tanks for maturing bitumen rubber and polymer blends.

The D&H Horizontal Mixing Chamber effectively inline blends batches of all sizes – from small batches to continuous large-scale production. The mixer is designed to ensure greater consistency than high speed impeller mixing tanks and ensures less air injection than vortex mixing systems, while providing the assurance of completely coating the solid particles with bitumen.

The D&H Horizontal Mixing Chamber includes the following features:

- Field-proven for nearly a decade to handle heavily-modified bitumen blending production rates from 9 metric tons per hour up to 45 metric tons per hour of continuous use

- 322 litre , single-chamber, heat-jacketed chamber

- Two mixing stages, featuring a combination of flighting, breaker bars, and mixing paddles

- 200 rpm single-speed electric motor and gearbox

- Heat-traced with 50 mm high-density insulation

- Backflow preventative device with overflow and dual-redundant high-level safety switches

- 50 mm liquid inlet, 200 mm x 200 mm dry feed inlet, 150 mm outlet, 100 mm drain and 150 mm sump to catch foreign metals

Advantages of the mixer include:

- Greater mixing agitation and coating of rubber, polymer, or any dry powder with bitumen

- All product must pass completely through the mixing chamber

- Active mixing works with a wide range of production speeds

- Easily handles extremely highly-modified products, including 22% crumb rubber or 15% Styrene Butadiene Styrene polymer pellets

- Less air injection and oxidation potential than vortex systems

- Minimal maintenance, cleaning and equipment downtime

- Ease of maintenance: mixer is easy to completely drain and flush system clean

- Internal bushing on discharge side of auger eliminates any leaking from an auger seal

- Safer and more controlled system

- Not open to outside atmosphere

- Does not rely on gravity-fed discharge

- Product is mechanically fed through the system which does not allow froth to form on top of mixing product and any foaming or expansion is diverted downstream to larger storage tanks

- In polymer-modified blending systems, it can wet and deliver polymer to the high shear, PMB mill much faster

- More efficient milling in the high shear mixer because the polymer has not had time to heat and soften

- When polymer reaches the mill, it has a greater tendency to cut or shatter than extrude

Durban-based, Alan Wills & Associates (AWANDA) is the South African representative for US company D&H Equipment.

EMAIL THIS ARTICLE SAVE THIS ARTICLE

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here