Chlorine dioxide is receiving increased attention in various industrial markets for the treatment of water and, increasingly, in the food and beverage industry. This is according to Jakes Jacobs, disinfection technologist and director for Nanotech Water Solutions.

“A disinfection strategy in the food and beverage industry is seldom thought about when the legislation is continuously referring to one component, for example chlorine, despite its long term carcinogenic effect,” he notes.

It is for this reason that Nanotech has spent years in developing a locally manufactured technology with over 60 applications installed to prove the technology and to achieve compliance.

With applications in abattoirs, alcoholic and non-alcoholic beverages, food processing and potable water, on-site manufacturing technology of chlorine dioxide has proven to be up to three times better than chlorine and other treatment programmes.

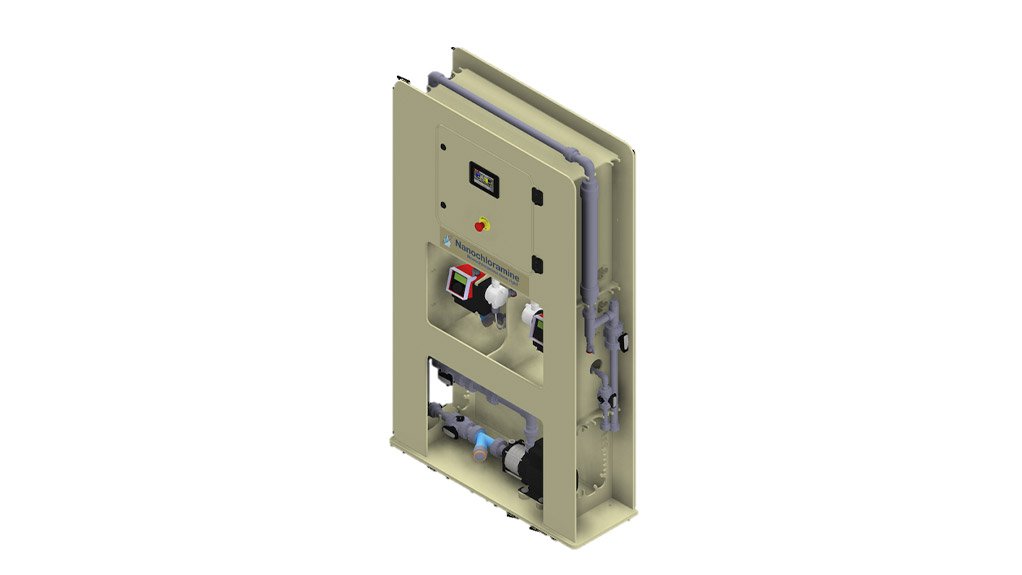

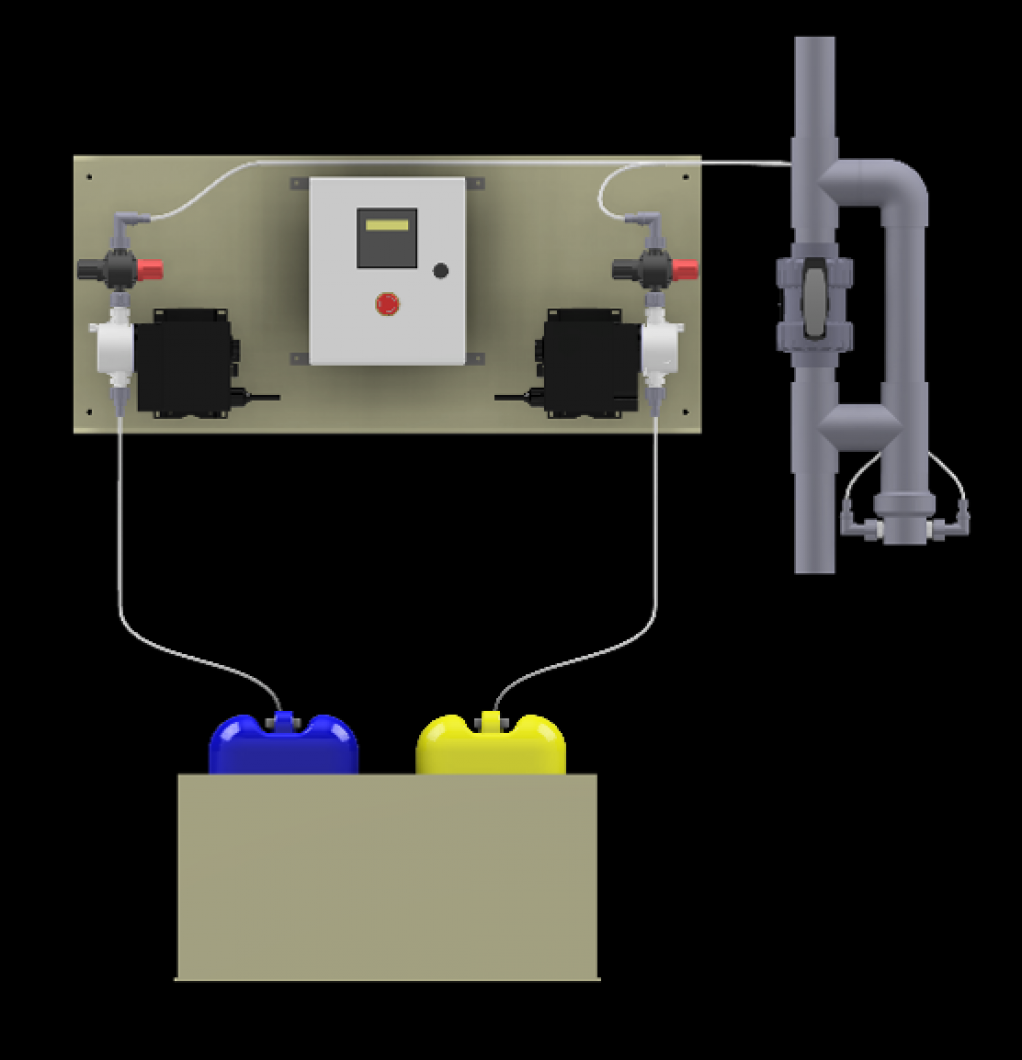

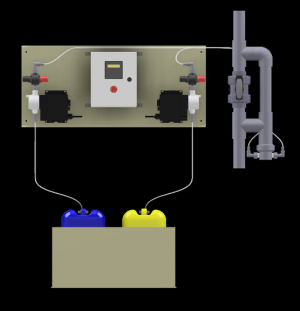

Jacobs explains that the chemical reaction producing chlorine dioxide occurs “under water” and results in a 40% reduction in acid consumption. “The concept has been patented for its uniqueness,” he notes.

The reduced acid consumption directly results in significantly reduced chlorides in the process and lower corrosion rates. Chlorine dioxide is used as a strong oxidant in pre-oxidation (iron and manganese) and disinfection of water sources.

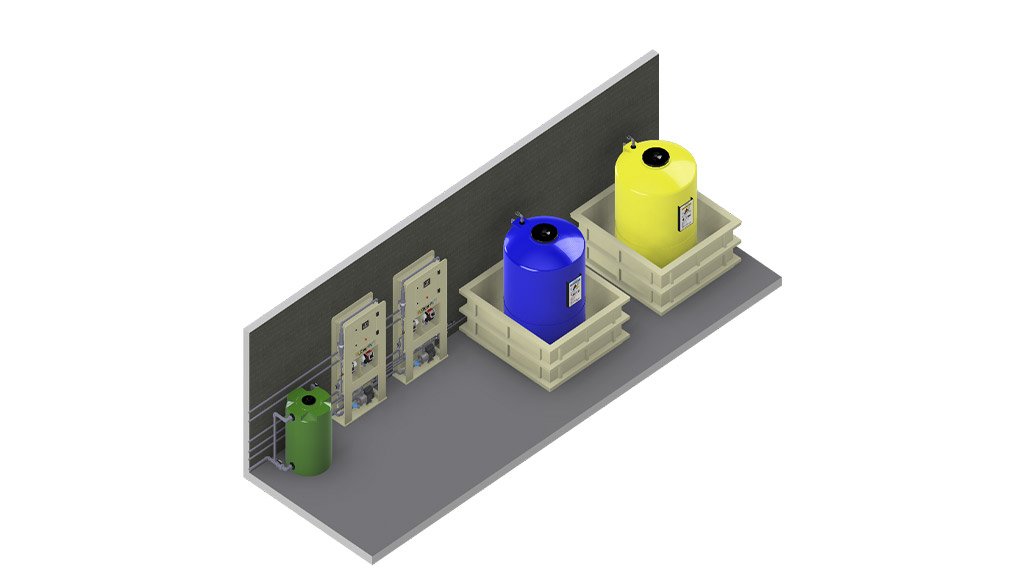

After intrinsically mastering chlorine dioxide generator technologies over 15 years, Nanotech has developed its own superior technology and has become the leading manufacturer of the technology, exporting high quality generators to industries that are in dire need of cost-effective, efficient and reliable solutions.

Nanotech used the same engineering expertise and experience to develop another locally available technology: the on-site manufacturing of monochloramines. The generators use the same material for construction, electrical panels and assembly line.

This eliminates the capital cost of development, delivering a quality product unequalled by international competitors. Monochloramines are the excellent choice for secondary disinfections, primarily because they are longer-lasting, and produce less disinfection by-products.

The onsite manufacturing capability of chlorine dioxide and monochloramine is gaining significant momentum against traditional methods like chlorine gas and chlorine derivatives.

On-site manufacturing eliminates the volume of other disinfection chemicals to be kept on site. “Considering that a lot of sites are remotely located, on-site manufacturing makes better sense,” Jacobs claims.

Meanwhile, Nanotech has discovered that compliance, competence and commitment (the three C’s) are necessary for the water industry, and has subsequently proven this concept to be the perfect management technique.

“The application of the three C’s and the incorporation of tailored chlorine dioxide and monochloramine technologies will continuously deliver micro compliance for the food and beverage industry,” he concludes.

Edited by: Creamer Media Reporter

EMAIL THIS ARTICLE SAVE THIS ARTICLE

ARTICLE ENQUIRY

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here