With a focus on continuous innovation, science multinational DuPont is developing a new and improved clear Tedlar film to increase efficiency and the life of a solar panel well beyond the industry standard of 30 years.

The Tedlar film is made of polyvinyl fluoride polymer – which is a more reliable and durable protective coating, offering a lighter weight solution for bifacial panels.

Bifacial panels, in contrast to the conventional monofacial photovoltaic (PV) solar panels, convert solar irradiance captured on both the front and back sides of the panel into electrical power.

“We aim to increase efficiency well beyond the normal system life span towards 40 years, while increasing system safety and reducing costs,” notes DuPont Europe, Middle East and Africa regional marketing manager Stephan Padlewski.

He adds that DuPont is also working on new metallisation pastes to continue to improve the efficiency of solar panels, while reducing the overall cost of solar PV plant ownership.

Generally, weather-sensitive materials will degrade more with age and faster in an environment with increased temperature. This particularly affects the backsheet protection, which is exposed to both ultraviolet and combined thermal and humidity stresses. It is therefore particularly important to select the most robust materials for installations in hot and arid climates, such as those found in sub-Saharan Africa.

DuPont has been engaged in an extensive field survey programme for the past five years in order to help catalogue and understand panel level defects. This survey has now yielded statistics on more than 1 GW of panels across three continents with an average age of 3.3 years over a range of panels aged one to 27 years. This data was gathered on 286 installations globally spanning 45 different brands of solar panels.

DuPont’s statistics reveal strong trends both by climate and by application. These trends show the determining impact of temperature on defects. “Roof-mounted installations show defects similar to installations in hot climates, although a majority of our roof statistics were gathered in a temperate environment. The defect levels are about three times as high for a hot environment as for a temperate environment,” he explains.

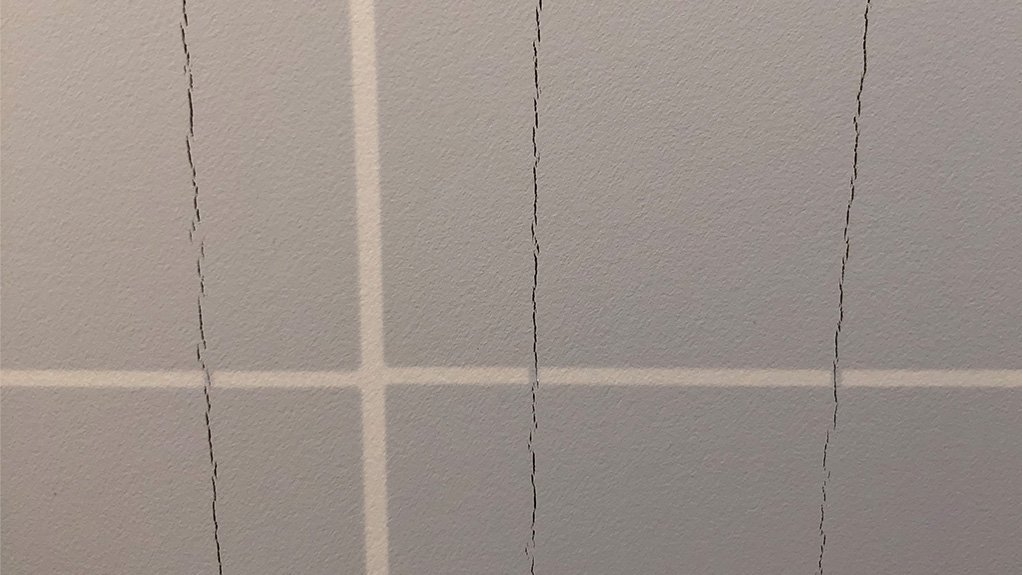

The other determining factors highlighted in its study are the impact of materials and age of the backsheet materials. With the exception of polyvinyl fluoride-based backsheets, most materials start showing some signs of ageing after about three to four years in the field, such as yellowing on the back and front side of the backsheet, the formation of micro cracks and also deep cracks that can lead to the loss of the dielectric protection of the panel.

African Outlook

Padlewski adds that, in the sub-Saharan region, including South Africa, renewables are establishing a stronger foothold.Solar will account for 9% of new energy capacity in Africa in the next two years.

He goes on to explain that Africa is proving to be a growth market as well and is likely to drive investment numbers. The World Bank estimates that, if sub-Saharan Africa’s economies had dependable electricity, gross domestic product growth across the region could be up to 2% higher a year than current rates.

“Africa is seen as an excellent home for grid scale and minigrid power projects to reach all 1.2-billion of its inhabitants.”

Taking into consideration the fast growth of the sub-Saharan Africa solar market, DuPont has appointed renewable- energy company YG Energy Africa director and owner Christopher Steinbach as DuPont downstream ambassador for the region.

In this role, Steinbach engages with investors, project developers, engineering, procurement and construction contractors as well as financiers and technical consultants to promote the importance of quality and reliability in the selection of solar plant equipment. More so, in the understanding of carefully selecting materials making up solar panels and assets, to help mitigate risks of premature degradation and protect long-term investment.

“DuPont is confident that his deep understanding of the challenges and complexities of the various solar markets in the region are a valuable asset,” asserts Padlewski.

Edited by: Zandile Mavuso

Creamer Media Senior Deputy Editor: Features

EMAIL THIS ARTICLE SAVE THIS ARTICLE

ARTICLE ENQUIRY

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here