Owing to ongoing research and development (R&D), rigging and lifting equipment provider Kelmeg Lifting Services has expanded its product offering, which resulted in significant growth over the past five years, says Kelmeg factory manager Rodney Young.

Kelmeg is a division of equipment supplier Renttech SA. However, this does not limit the company’s additional product offerings to the market – the company’s products are avail- able through a distribution network throughout South Africa.

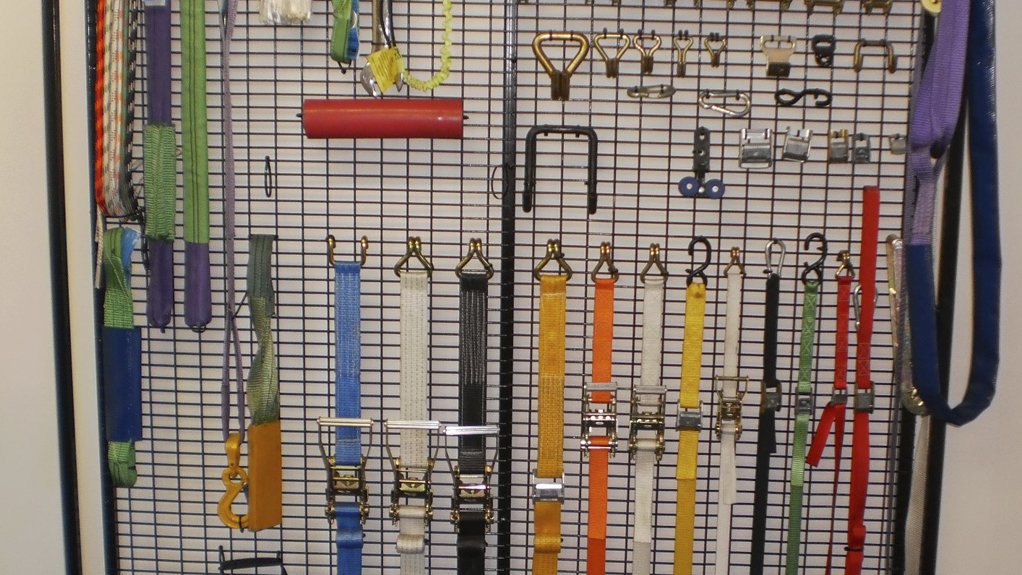

Kelmeg, through parent company Renttech SA and numerous other distributors, has had a significant input into the heavy lifting industry on various projects, ranging from petrochemicals plant shutdowns to power generation marine maintenance and offshore projects. The company has supplied flat webbing, chain blocks, lever hoists and wire rope winches.

Young adds that Kelmeg has not only diversified its product offering but also achieved a sustainable footprint in all markets across various industries. This is achieved through offering customised, project-specific products relating to length and size requirements.

He says that safety is a critical factor for Kelmeg owing to the growing demand for high-quality rigging and lifting components that are endorsed by heavy industry body the Lifting Equipment Engineering Association of South Africa (Leeasa), of which the company is a member.

“Kelmeg is mindful of the changing legislation in this regard and the company has an International Organisation for Standardisation accreditation and manufactures in accordance with the SANS 94-1 and SANS 94-2 specifications as required by the latest Driven Machinery Regulations,” Young points out.

Along with the R&D that has triggered growth for the company, Kelmeg also invests in in-house training of its personnel across the board in order to manufacture high-quality products. The company employs lifting machinery inspectors (LMIs) and lifting tackle inspectors (LTIs).

The LMI qualifications are recognised by the Engineering Council of South Africa, which provides training and refresher courses. An indi- vidual should have at least five years’ experience in a chosen field of lifting, such as rigging equipment, in order to qualify as an LMI.

“The council carefully scrutinises the indi- vidual’s competence in the field of machinery lifting and rigging equipment, after which they are required to write an exam before being [awarded] accreditation,” Young explains.

The course for qualification as an LTI is a much shorter process – besides industry experience, an applicant attends a ten-hour course, followed by a written examination, Young says.

Kelmeg facilitates the process of acquiring LMI and LTI qualifications by assisting applicants to gain the necessary knowledge and experience.

“There is a continuous need for LMIs and LTIs in all sectors of the lifting and rigging market. Kelmeg is proud to able to provide industry with this level of expertise and service,” Young concludes.

Edited by: Zandile Mavuso

Creamer Media Senior Deputy Editor: Features

EMAIL THIS ARTICLE SAVE THIS ARTICLE

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here