The US National Fire Protection Association reports that machine fires are the fourth leading cause of fires in industrial environments in the US, making the use of flame-retardant cabling materials a safety-critical requirement.

Cable manufacturer, igus has received certification from Underwriters Laboratories (UL) for its high-end thermoplastic elastomer (TPE) cables that do not use fire-retardant halogens as additives. This is said to be the first time that the US testing organisation has recognised that halogen-free TPE cables can also meet the fire protection requirements in industry.

"That is why we are particularly pleased that igus has now become the world's first manufacturer to receive a UL seal for halogen-free TPE cables," says Rainer Rössel, VP and head of the chainflex cables business unit at igus. "The approval demonstrates to our customers that they have the safety aspect covered with chainflex high-end TPE cables."

Up to now, UL approval has been granted only for products containing flame retardants such as chlorine, fluorine or bromine – additives which all increase flame retardancy. However, the flame retardants can also change the chemical structure of the jacket and reduce the mechanical load-bearing capacity. igus says that the design of its TPE cables focuses on how the cable itself causes a fire and less on preventing a fire from spreading. The company explains that its TPE jacket compounds are extremely resistant to mechanical loads as well as external influences and can be used in a wide range of applications such as small installation spaces of up to 4xd, on highly dynamic, short travels with accelerations of 100m/s² or on long travels in a temperature range from -35 °C to 100 °C.

The compounds are also said to be extremely media resistant, even with special organic oils. The halogen-free TPE jacket compounds help to minimise premature aging of the outer jacket by a factor of up to 10, compared to the same materials containing flame retardants. This means that the jacket does not break the cable and therefore cannot cause a fire, as there is no reduction in the cross section of the cores.

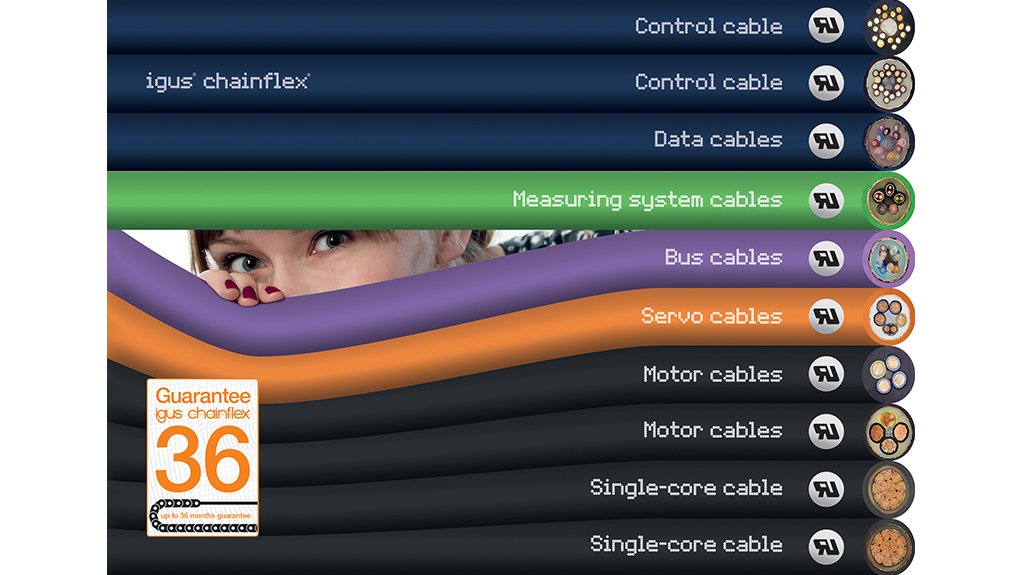

The company states that the long-term flexural strength and service life of chainflex cables in the e-chain have been proven in its in-house igus testing laboratory. "So far, customers have already had the opportunity to choose from 1 044 chainflex cables with UL approval," Rössel notes. "With the new certification, there are now more than 200 TPE cables, so we can offer an almost complete UL certified product range."

EMAIL THIS ARTICLE SAVE THIS ARTICLE

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here