Engine, filtration and power- generation product manufacturer Cummins notes that gas-powered gensets are a sustainable power solution, owing to natural gas being methane rich and occurring naturally. This makes it a cost-effective alternative energy source, compared with wind and solar power.

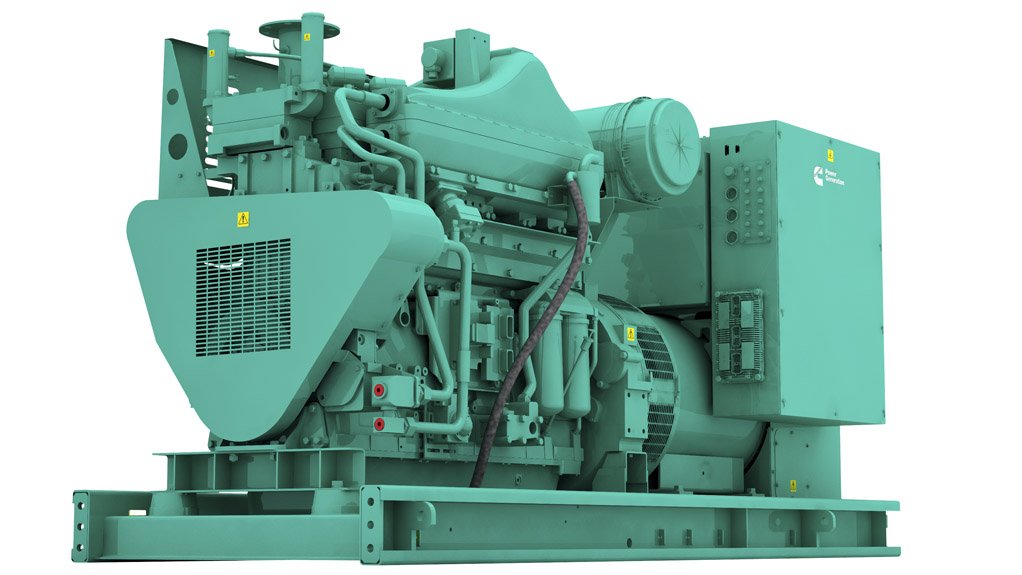

During the first leg of its power tour roadshow, which started in June, Cummins Southern Africa power generation director Kenny Gaynor said Cummins’s gas-powered gensets were individual standalone units ranging from 25 kVA to 2 000 kVA.

The gensets are configured and integrated to form multiple-unit power plants and the product range can cater for any business application, regardless of location.

“An important feature of the gas-powered gensets is the built-in heat-recovery process, which negates the need for air-compressor-driven cooling systems. The heat expelled from the exhaust of the genset is recycled to provide air pressure for the refrigeration unit,” he explained.

Gaynor further indicated that this was a major innovation, as older generators used dump radiators to keep the system cool. The heat-recovery system made the generators more efficient, as additional energy to drive the refrigeration system was no longer required, he added.

Cummins gas-powered gensets could return unused power back to the utility grid, enabling profit generation through the selling of surplus electricity, Gaynor said, adding that this, alongside the products’ added efficiency and reduced carbon tax liability meant that the products were self-sustaining in the long term.

“As South Africa begins its journey towards a less coal- dependent power mix, the decision-makers at the Department of Energy would be well tipped to observe this kind of new technology closely, as plans to establish gas as a source of power for the national grid are drawn out,” he pointed out.

Turning his attention to the importance of diesel-powered backup gensets, Gaynor emphasised two critical benefits. Firstly, operations and processes could continue seamlessly using backup gensets, “whether in a manufacturing environment or in a hospital”, he said.

Secondly, critical safety processes, such as headgear, liftshafts and ventilation systems, depended entirely on reliable and uninterrupted power supply, which could be ensured when using Cummins gensets, he added.

Moreover, Gaynor pointed to the company’s power systems that complement national grids, as well as gensets that were immediately and automatically available in the event of a power-supply interruption.

He said that the cost of alternative or complementary power generation would always be higher than baseload utility power generation, but that the benefits of uninterrupted power in business or industry were clear.

One of the three gensets showcased was the C315N5C natural-gas-powered generator, a gas genset with a fully integrated power-generation system that uses high-quality technology to provide optimum performance and efficient use of fuel for continuous duty, as well as combined heat and power and peaking applications. The product features a Cummins heavy-duty engine, with a rugged four-cycle lean-burn gas combustion engine, controlled by electronic engine management and monitoring technology.

Gaynor asserted that the company ensured the continuous and reliable supply of parts for maintaining and repairing the gensets, all of which were manufactured using Cummins parts only, which meant all the components in the gensets could be serviced and maintained by Cummins. “Cummins products are all backed by a comprehensive warranty, which includes the provision of professional support from the worldwide dealer network.”

He noted that the benefits tied to gas-generated power were multifaceted and that they easily outweighed the costs associated with the purchase of such a generator. “Operational safety is ensured by the introduction of a continuous uninterrupted power supply, while environmental impacts are decreased drastically when switching to gas-fuelled gensets,” he concluded.

Edited by: Zandile Mavuso

Creamer Media Senior Deputy Editor: Features

EMAIL THIS ARTICLE SAVE THIS ARTICLE

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here